Experimental study on characteristic calibration of separated exhaust system

-

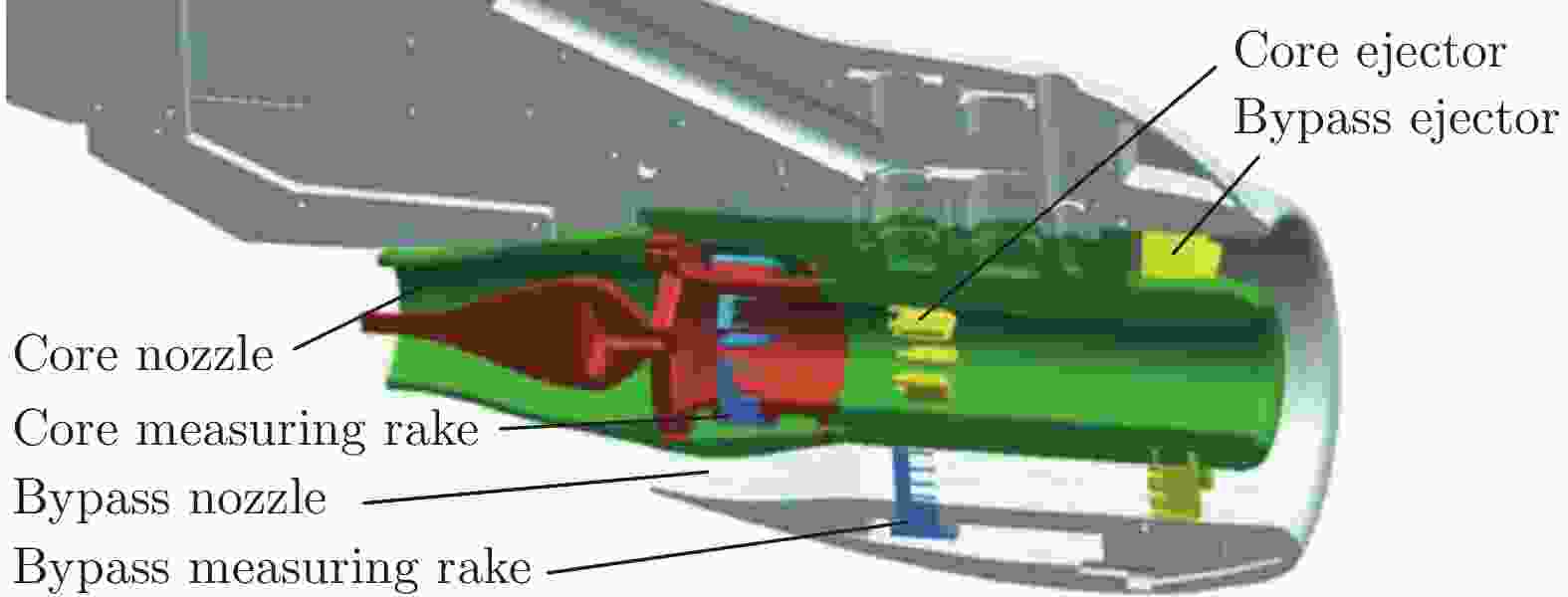

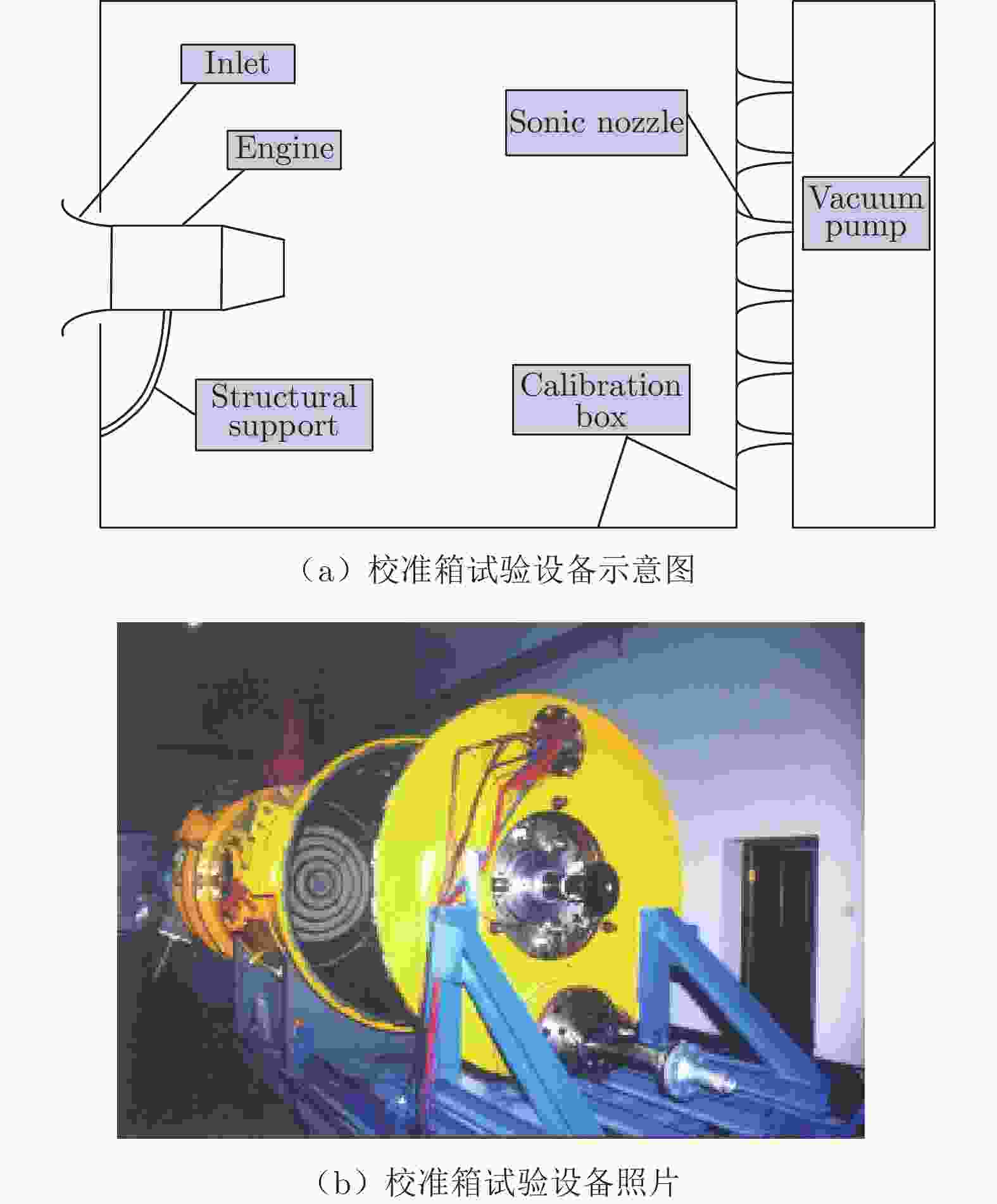

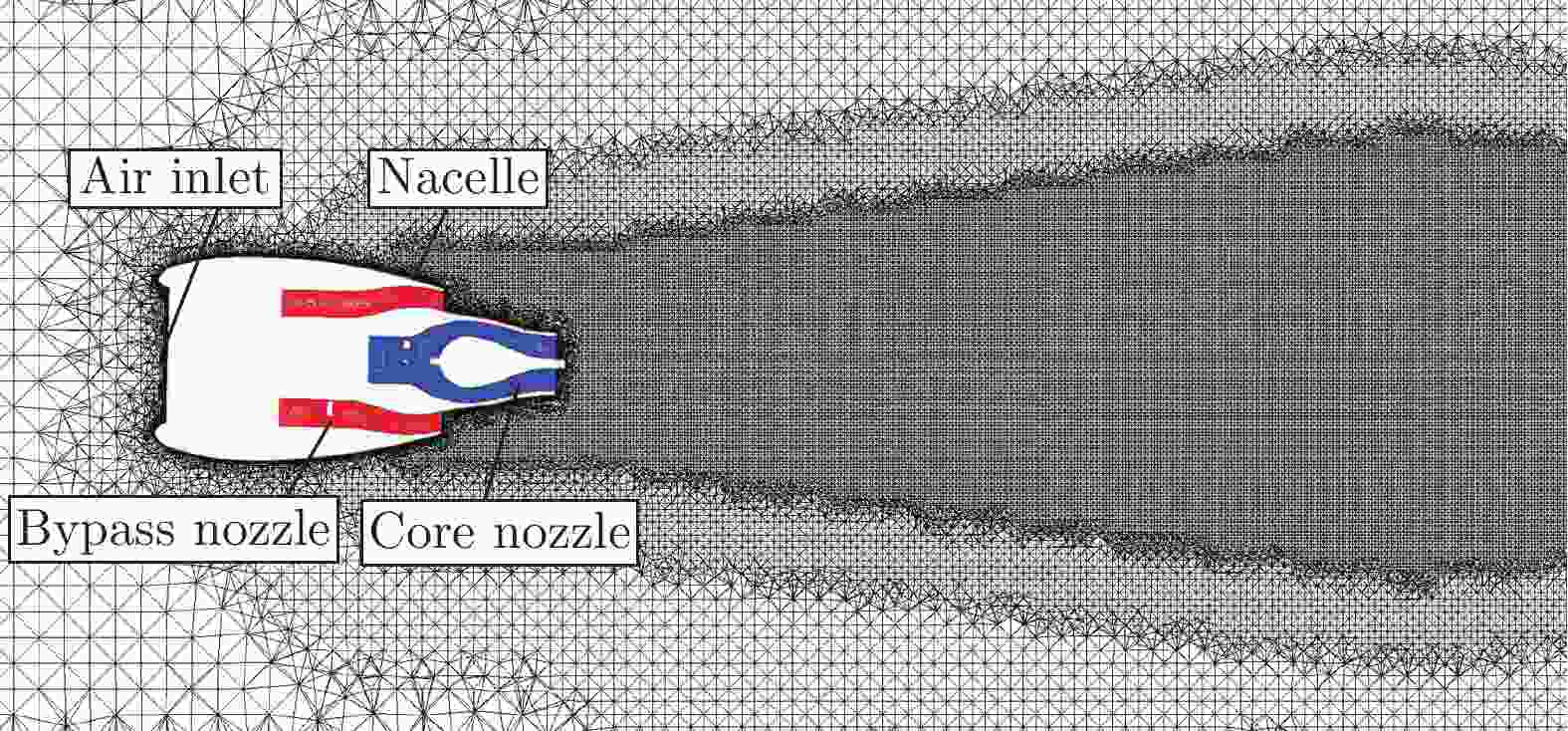

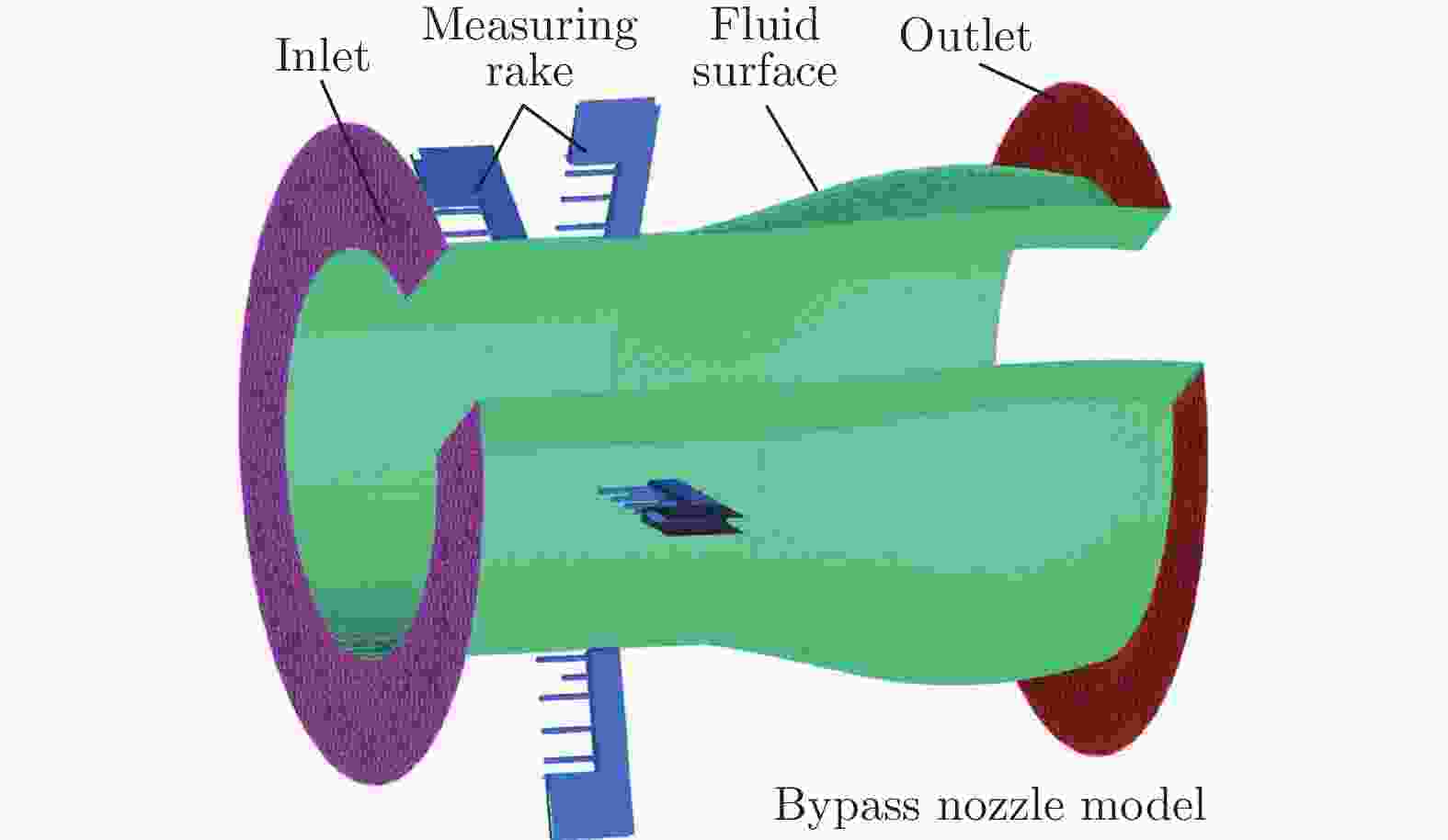

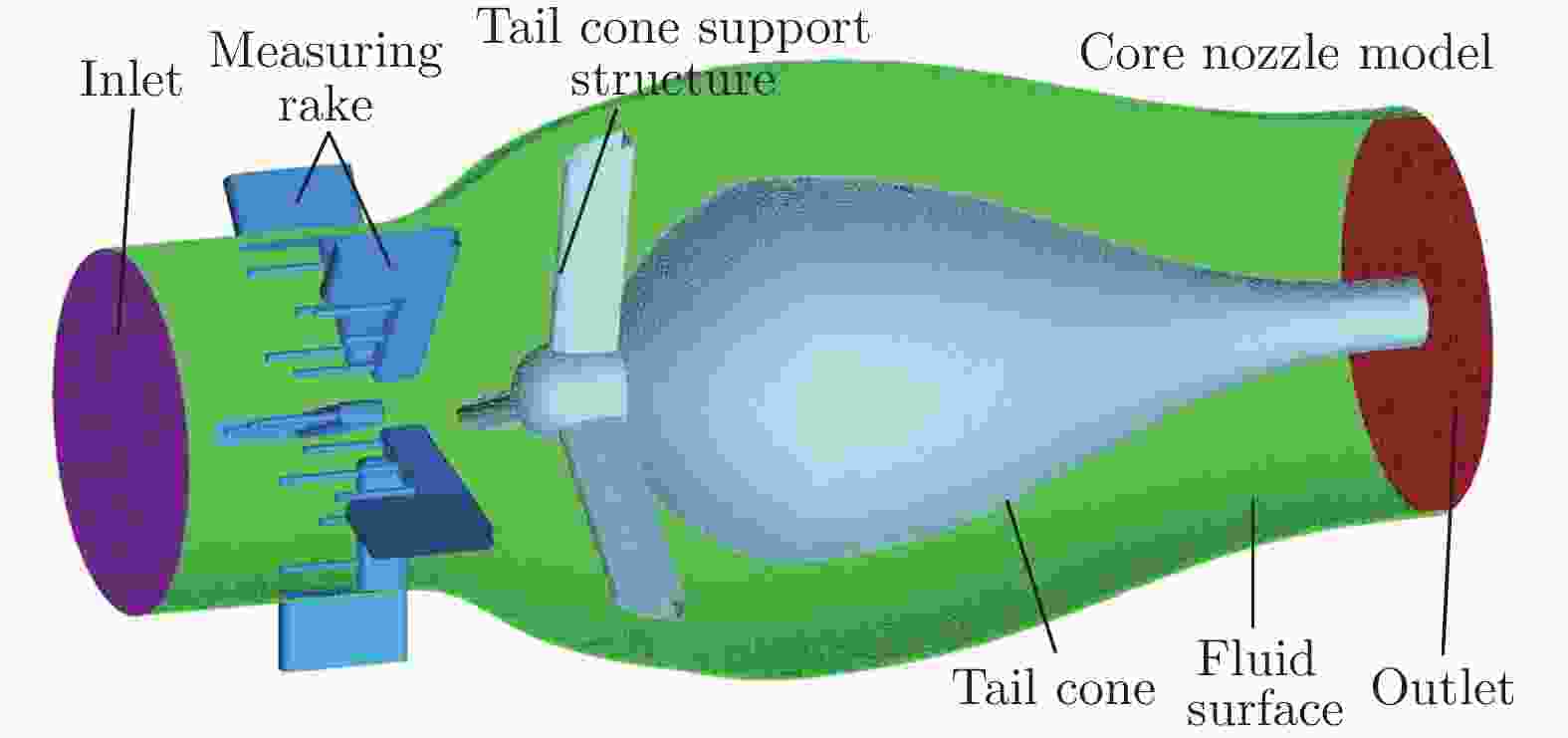

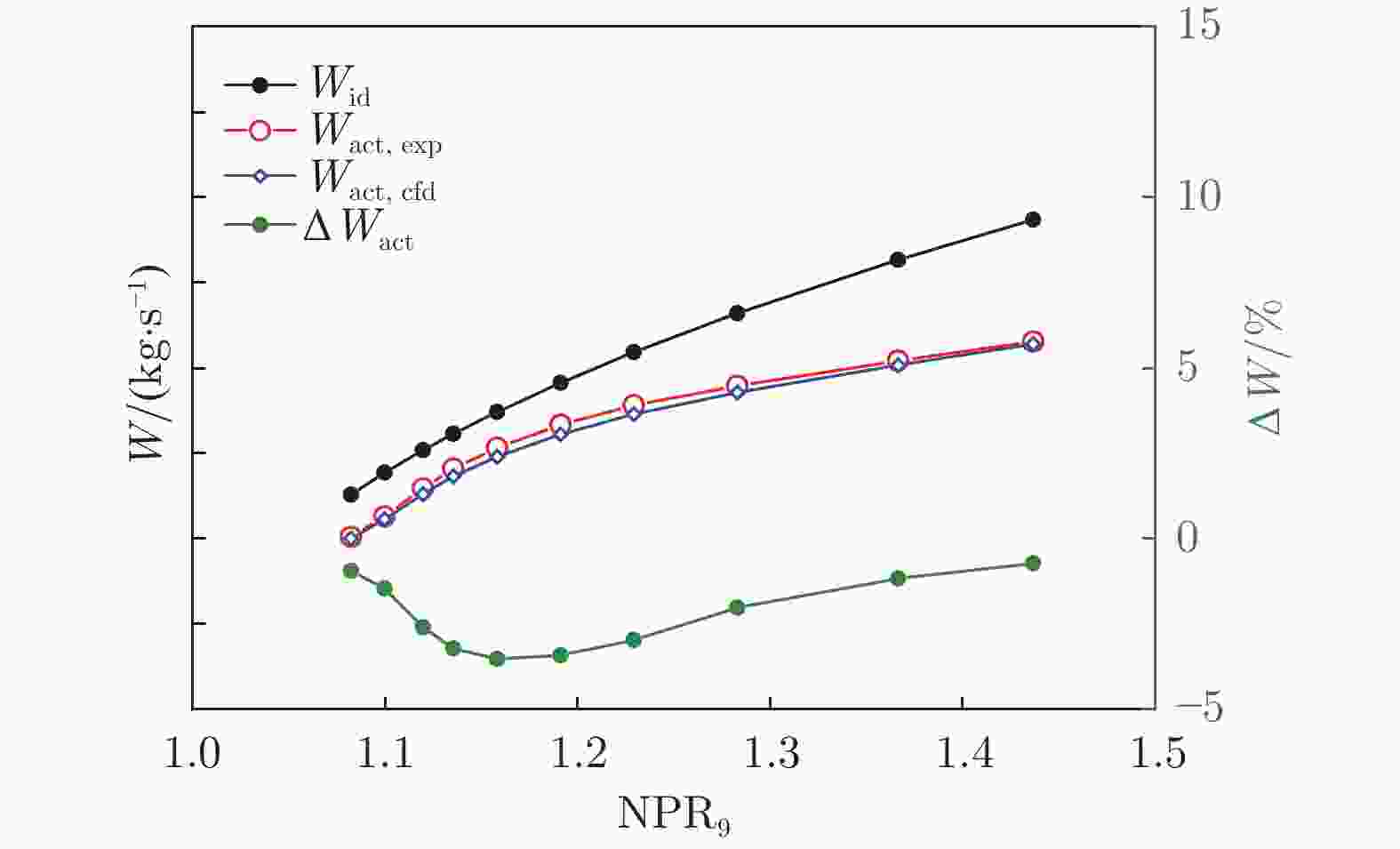

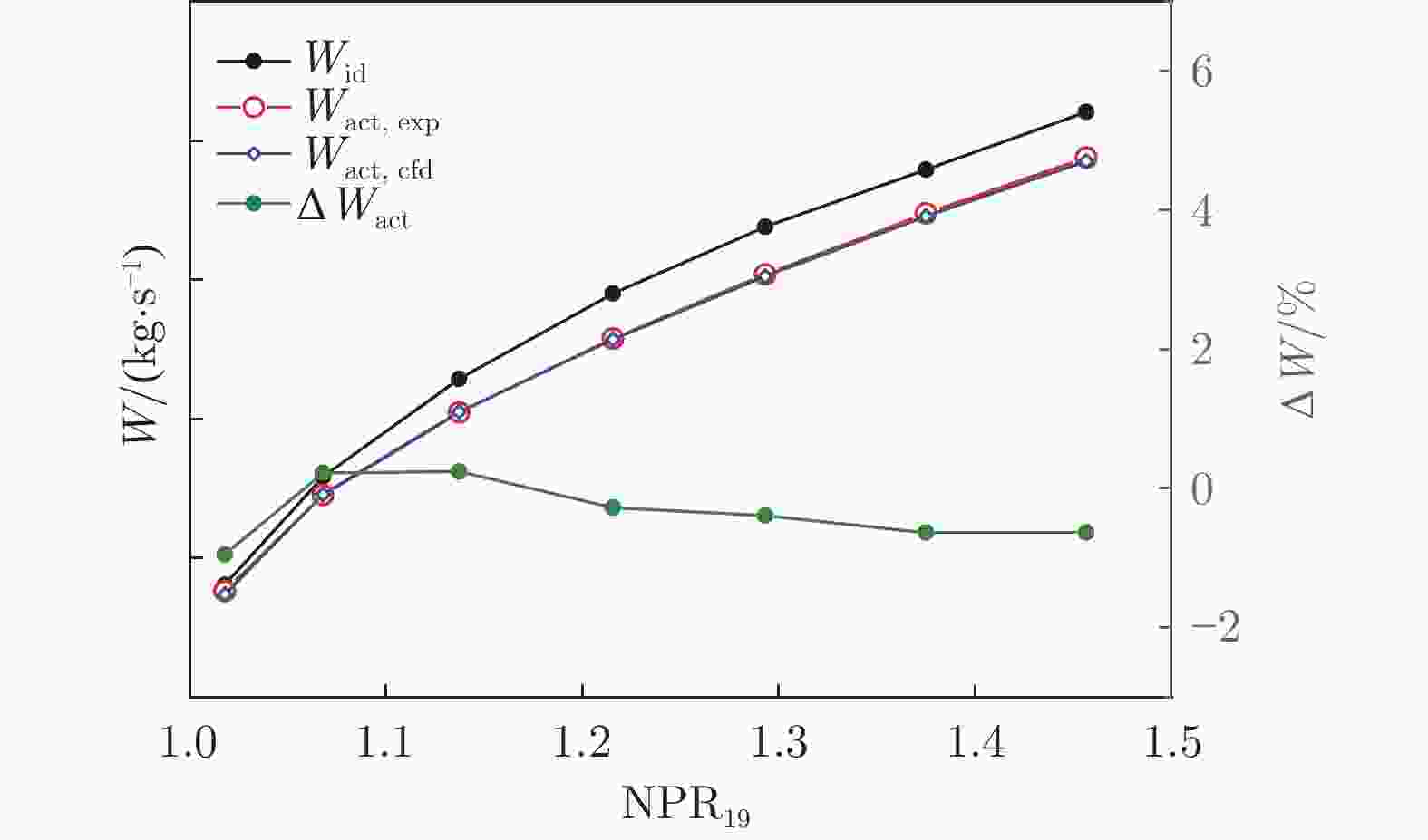

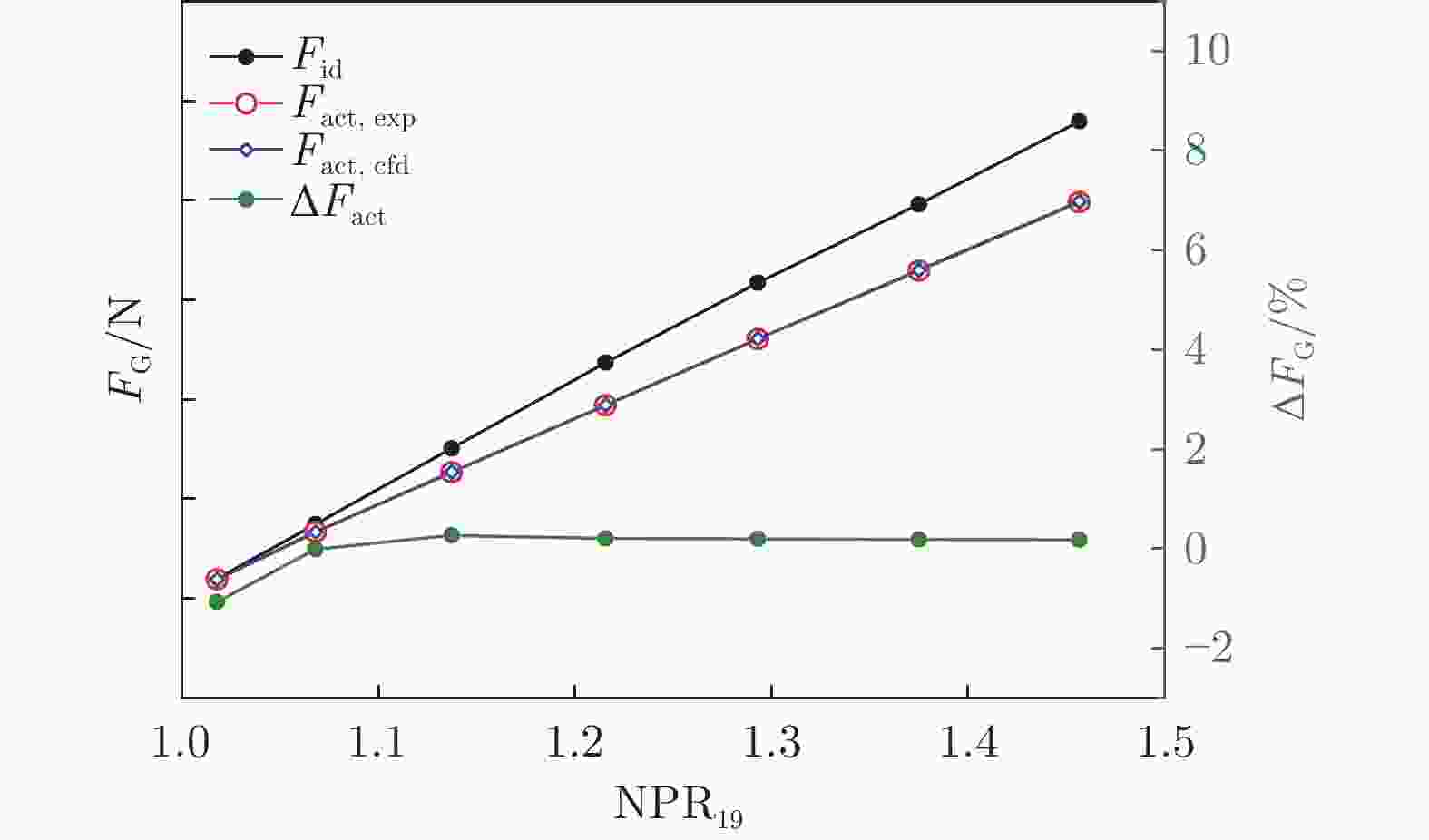

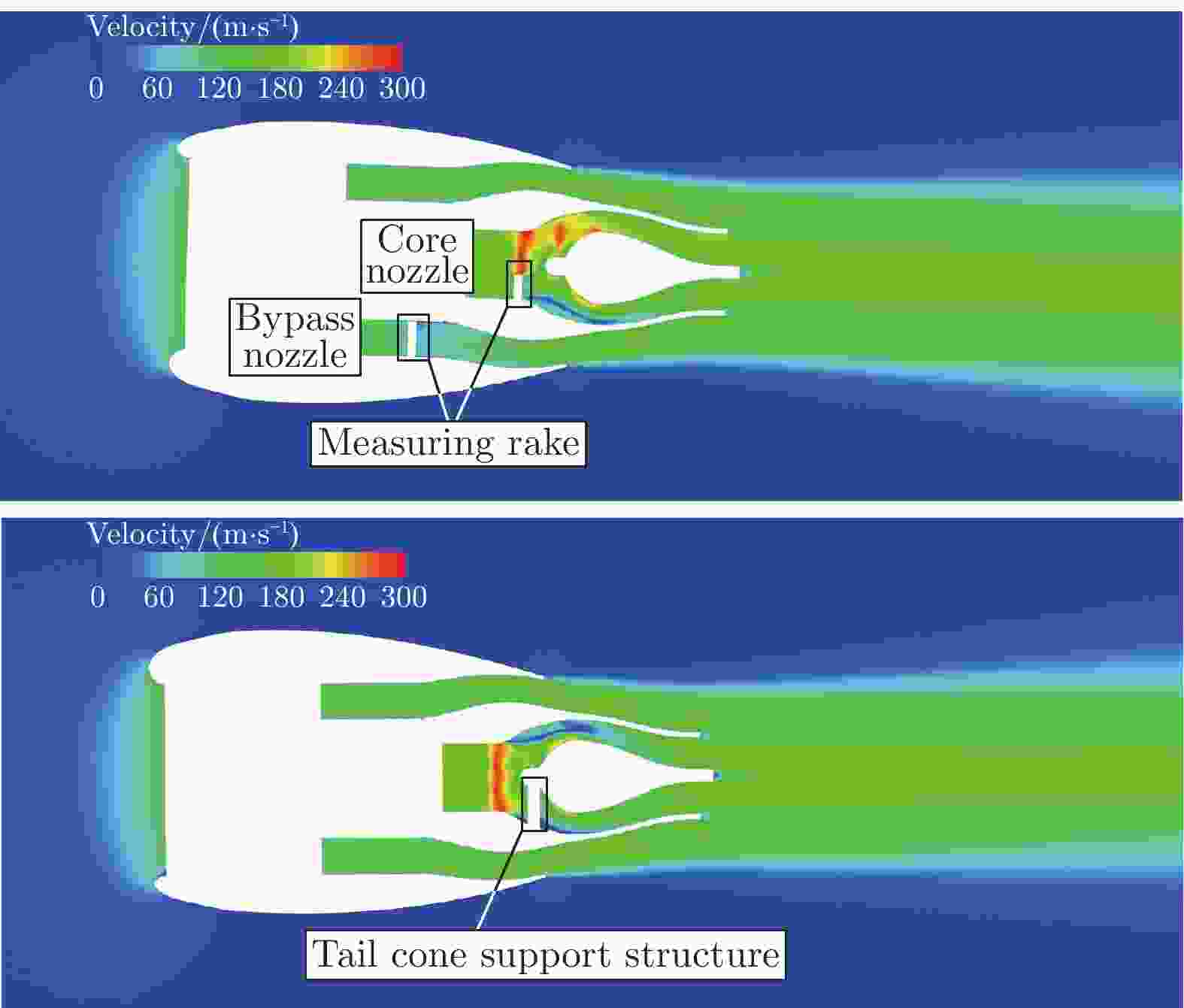

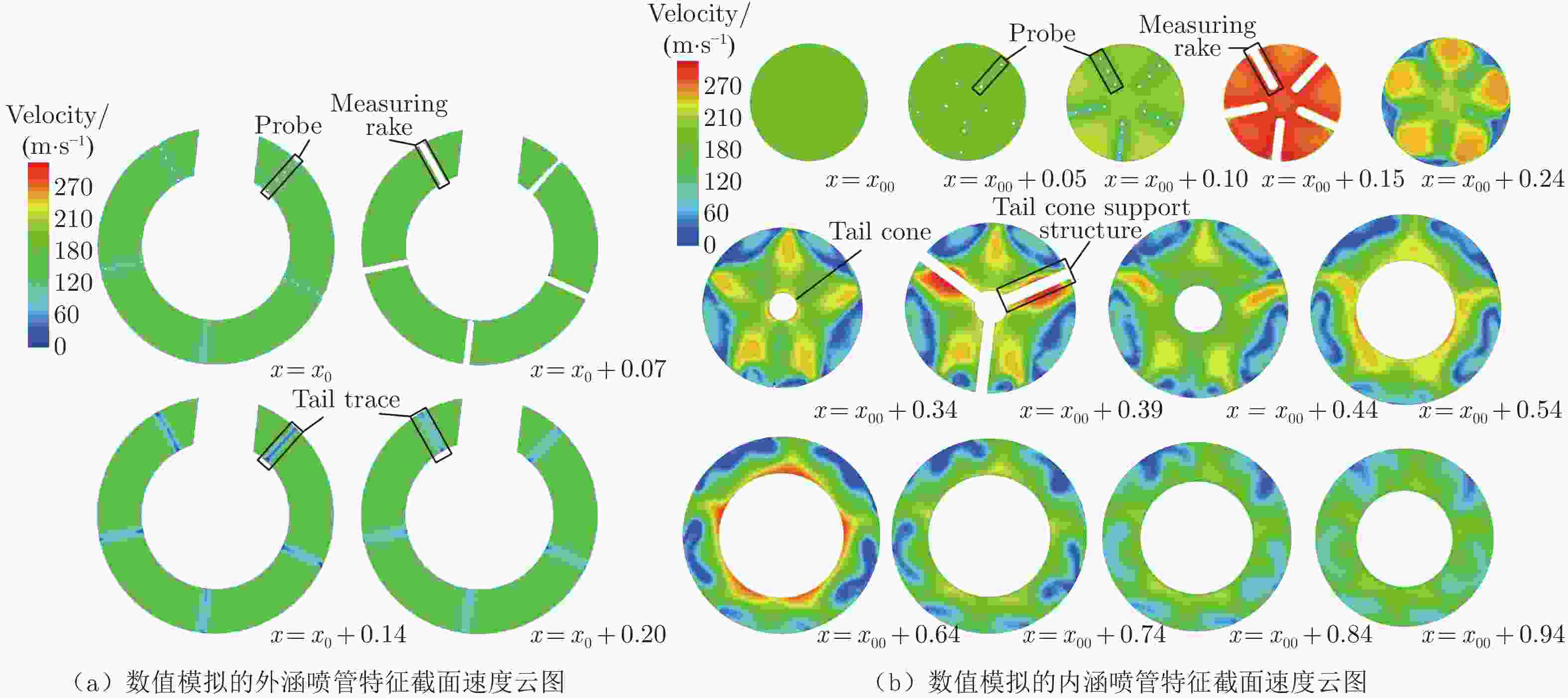

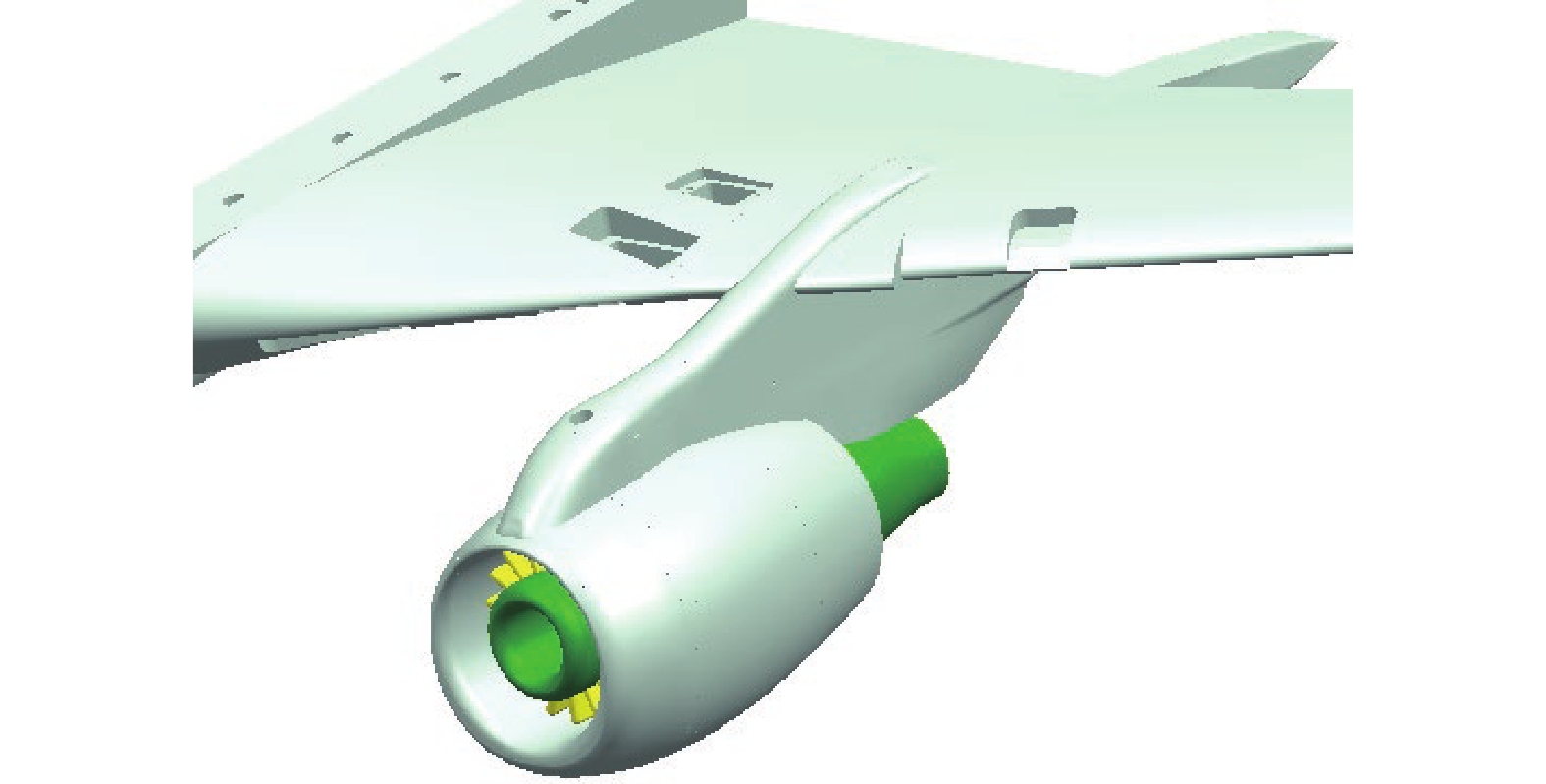

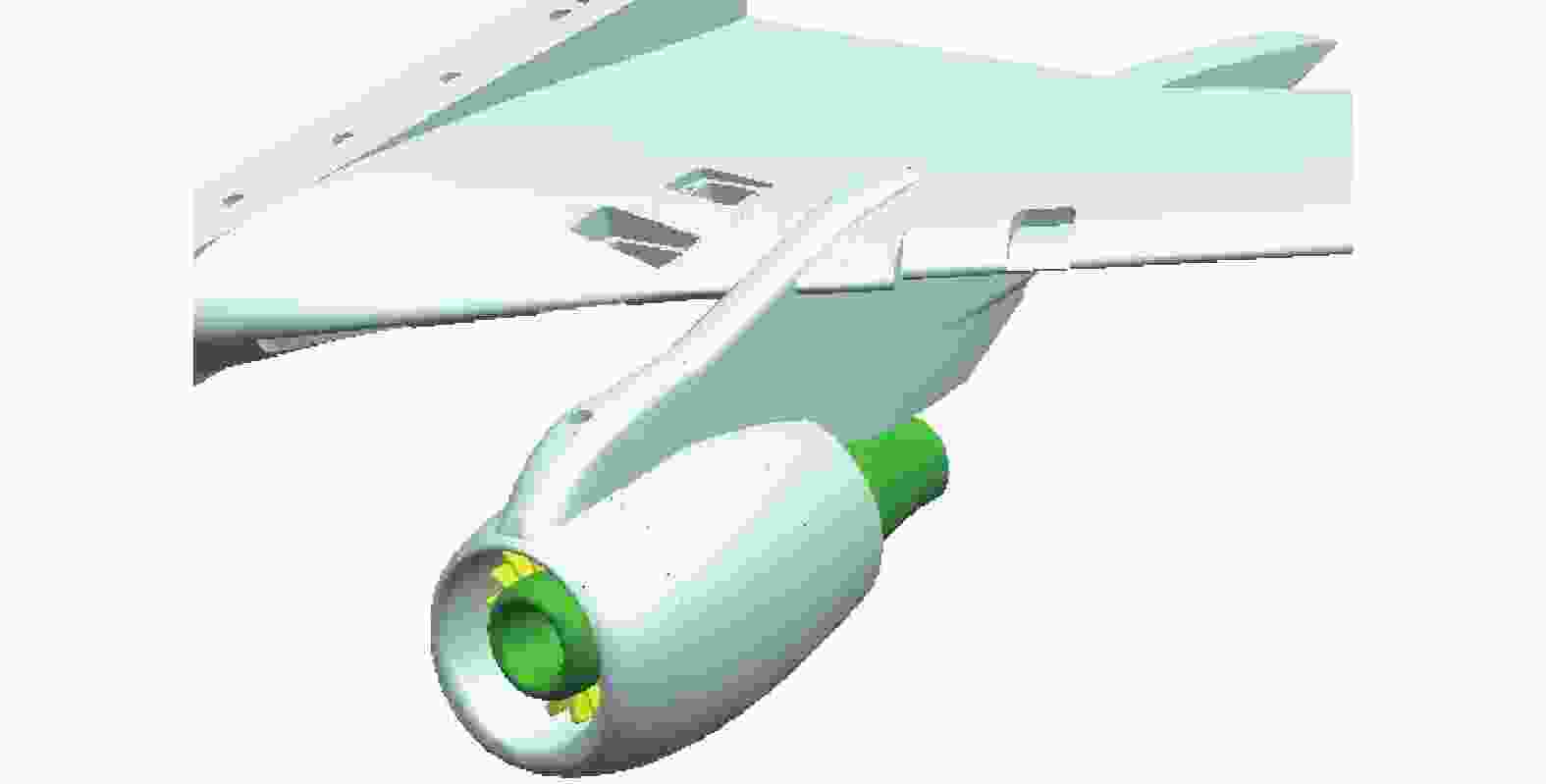

摘要: 飞行试验时,采用燃气发生器法间接获取航空发动机飞行推力。为提高飞行推力计算精度,需准确获取航空发动机排气系统特性。采用某大涵道比分开排气系统缩比模型开展了实验室校准箱吹风试验及数值模拟研究,结果表明:采用实验室校准箱吹风试验、数值模拟获取的单独内涵喷管特性趋势一致、数值接近,最大内涵喷管压比为1.44时,喷管流量和推力偏差分别为0.73%、0.18%;通过试验和数值模拟获取的内外涵分开排气系统特性趋势一致、数值接近,最大外涵喷管压比为1.46时,喷管流量和推力偏差分别为0.64%、0.18%;对大涵道比分开排气系统物理模型与几何模型进行合理简化后,试验和数值模拟获取的分开排气系统特性偏差满足工程精度要求。Abstract: In flight testing, the aeroengine flight thrust is indirectly obtained by the gas generator method. In order to improve the calculation accuracy of the flight thrust, it is necessary to accurately obtain the characteristics of the exhaust system. The laboratory calibration test and numerical simulation research were carried out by using the large bypass ratio separated exhaust system scale model. The results show that: the core nozzle characteristics obtained by the two methods are consistent, and the values are close. When the maximum core nozzle pressure ratio is 1.44, the deviations of the mass flow and the thrust are 0.73% and 0.18%, respectively; the characteristics of the separated exhaust system obtained by the two methods have the same trend and close values. When the max bypass nozzle pressure ratio equals 1.46, the deviations of the mass flow and the thrust are 0.64% and 0.18%, respectively; when the physical model and geometric model of the large bypass ratio separated exhaust system are reasonably simplified, the characteristic deviations of the separated exhaust system obtained by the two methods are in good agreement.

-

Key words:

- exhaust system /

- nozzle characteristic /

- calibration /

- large bypass ratio

-

L 流向特征尺寸 D 截面特征尺寸 NPRcr 喷管临界压比 NPR 喷管压比 NPR9 内涵喷管压比 NPR19 外涵喷管压比 Cd 喷管流量系数 Cfg 喷管推力系数 Cfg9 内涵喷管推力系数 Cfg19 外涵喷管推力系数 FG 推力/内外涵喷管总推力 FG9 内涵喷管推力 FG19 外涵喷管推力 FG, act 内外涵喷管实际总推力 FG9, act 内涵喷管实际推力 FG9, id, non 内涵喷管无量纲理想推力 FG9, id 内涵喷管理想推力 FG19, id 外涵喷管理想推力 Fid 内外涵喷管理想总推力 Fact, exp 内外涵实际总推力(校准试验) Fact, cfd 内外涵实际总推力(数值模拟) ΔFact Fact, cfd与Fact, exp之间的偏差 W 流量 Wid 内外涵喷管理想总流量 W9, act 内涵喷管实际流量 W19, act 外涵喷管实际流量 Wact, exp 内外涵实际总流量(校准试验) Wact, cfd 内外涵实际总流量(数值模拟) ΔWact Wact, cfd与Wact, exp之间的偏差 W9 内涵喷管流量 v9 喷管出口速度 A9 内涵喷管出口面积 ps0 环境压力 ps9 内涵喷管出口静压 pt9 内涵喷管出口总压 pt19 外涵喷管出口总压 Tt9 内涵喷管出口总温 k 绝热指数 S 系统偏差 B 固定偏差 t 测量值或计算结果 j t的影响因素的总数 xi t的第i个影响因素 ui 第i个因素对t的不确定度 Ut 所有因素对t的不确定度 ci t对第i个因素的敏感系数 表 1 试验传感器采集精度

Table 1. Sensor precision

传感器 精度 压力传感器 ±0.1% 温度传感器 ±0.5 K 流量计 ±0.05% 六分量测力天平 ±0.03% 表 2 单独内涵喷管试验主要状态参数

Table 2. The core nozzle test parameter

NPR9 pt9/kPa Tt9/K W9, act/(kg·s−1) 1.08 107.7 299.3 0.202 1.10 109.4 298.4 0.226 1.12 111.4 298.4 0.259 1.14 113.0 298.4 0.282 1.16 115.2 298.4 0.307 1.19 118.5 298.5 0.334 1.23 122.3 298.4 0.357 1.28 127.6 298.2 0.379 1.37 135.9 298.3 0.408 1.44 142.9 298.2 0.431 表 3 内外涵喷管试验主要状态参数

Table 3. The separated exhaust system test parameter

NPR19 NPR9 pt19/kPa pt9/kPa Tt9/K W9, act/(kg·s−1) W19, act/(kg·s−1) 1.02 1.004 100.6 99.2 274.9 0.031 0.350 1.07 1.015 105.5 100.3 276.6 0.065 0.662 1.14 1.040 112.4 102.8 278.3 0.109 0.915 1.22 1.079 120.1 106.6 280.2 0.157 1.131 1.29 1.113 127.7 109.9 281.9 0.198 1.321 1.37 1.140 135.8 112.6 283.8 0.230 1.509 1.46 1.193 143.8 117.8 285.6 0.269 1.670 -

[1] 李新建, 齐海帆, 潘鹏飞. 某型分排涡扇发动机尾喷管特性影响参数研究[J]. 工程与试验, 2016, 56(1): 36–40, 84. doi: 10.3969/j.issn.1674-3407.2016.01.010LI X J, QI H F, PAN P F. Research on influencing parameters of jet nozzle characteristic of a certain type of turbofan engine[J]. Engineering & Test, 2016, 56(1): 36–40, 84. doi: 10.3969/j.issn.1674-3407.2016.01.010 [2] ASBURY S C, YETTER J A. Static performance of a wing-mounted thrust reverser concept[C]//Proc of the 34th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhi-bit. 1998: 3256. doi: 10.2514/6.1998-3256 [3] 高扬, 姜健, 屈霁云. 航空燃气涡轮发动机飞行推力确定[M]. 北京: 航空工业出版社, 2019. [4] 刘晓波, 孙宗祥, 钟萍, 等. 国外航空发动机空气动力学研究概况[J]. 燃气涡轮试验与研究, 2013, 26(4): 58–62. doi: 10.3969/j.issn.1672-2620.2013.04.013LIU X B, SUN Z X, ZHONG P, et al. An overview of aero-engine aerodynamics overseas research[J]. Gas Turbine Experiment and Research, 2013, 26(4): 58–62. doi: 10.3969/j.issn.1672-2620.2013.04.013 [5] HOLST K R. A method for performance analysis of a ramjet engine in a free-jet test facility and analysis of performance uncertainty contributors[D]. Knoxville: University of Tennes-see Knoxville, 2012. [6] ONERA. Annual report 2021[R/OL]. (2021) [2022-11-12]. https://www.onera.fr/sites/default/files/ressources_documentaires/RA-2021-VA.pdf. [7] MASSONNAT J-M, COTON T. Development in turbine testing at ONERA[C]//Proc of the 27th AIAA Aerodynamic Measurement Technology and Ground Testing Conference. 2010. [8] MODANE-AVRIEUX CENTER OF ONERA. BD2 Nozzle Thrust Measurement Bench[R/OL]. (2018) [2022-11-12]. https://www.onera.fr/sites/default/files/windtunnel/pdf/BD2%20test%20bench%20version%202018.pdf. [9] MODANE-AVRIEUX CENTER OF ONERA. TPS and nozzle mass flow and thrust measurements [R/OL]. (2004) [2022-11-12]. https://www.onera.fr/sites/default/files/windtunnel/pdf/S4B.pdf. [10] BURCHAM F W Jr. An investigation of two variations of the gas generator method to calculate the thrust of the afterburning turbofan engines installed in an F-111A air-plane[R]. NASA TN D-6297, 1971. [11] KURTENBACH F J, BURCHAM F W Jr. Flight evalua-tion of a simplified gross thrust calculation technique using an F100 turbofan engine in an F-15 airplane[R]. NASA-TP-1782, 1981. [12] RAY R J, COBLEIGH B R, VACHON M J, et al. Flight test techniques used to evaluate performance benefits during formation flight[C]//Proc of the AIAA Atmospheric Flight Mechanics Conference and Exhibit. 2002: 4492. doi: 10.2514/6.2002-4492 [13] 何成军, 李建强, 黄江涛, 等. 非对称超声速喷管内流动分离非定常特性[J]. 航空学报, 2022, 43(1): 302–312. doi: 10.7527/S1000-6893.2020.24930HE C J, LI J Q, HUANG J T, et al. Unsteadiness of flow separation in an asymmetric supersonic nozzle[J]. Acta Aero-nautica et Astronautica Sinica, 2022, 43(1): 302–312. doi: 10.7527/S1000-6893.2020.24930 [14] 刘福海, 朱荣, 董凯, 等. 拉瓦尔喷管结构模式对超音速射流流动特性的影响[J]. 工程科学学报, 2020, 42(S1): 54–59. doi: 10.13374/j.issn2095-9389.2020.03.15.s15LIU F H, ZHU R, DONG K, et al. Effect of Laval nozzle structure on behaviors of supersonic oxygen jet flow field[J]. Chinese Journal of Engineering, 2020, 42(S1): 54–59. doi: 10.13374/j.issn2095-9389.2020.03.15.s15 [15] 孙鹏, 周莉, 王占学. 出口宽高比对双涵道S弯喷管流动特性的影响[J]. 推进技术, 2022, 43(6): 122–132. doi: 10.13675/j.cnki.tjjs.201033SUN P, ZHOU L, WANG Z X. Effects of aspect ratio on flow characteristic of serpentine nozzle for turbofan[J]. Journal of Propulsion Technology, 2022, 43(6): 122–132. doi: 10.13675/j.cnki.tjjs.201033 [16] 何成军, 李建强, 范召林, 等. 单边膨胀喷管内流动分离非定常特性[J]. 航空动力学报, 2019, 34(11): 2339–2346. doi: 10.13224/j.cnki.jasp.2019.11.005HE C J, LI J Q, FAN Z L, et al. Flow separation unsteadiness in single expansion ramp nozzle[J]. Journal of Aerospace Power, 2019, 34(11): 2339–2346. doi: 10.13224/j.cnki.jasp.2019.11.005 [17] 孙鹏, 周莉, 王占学, 等. 双S弯喷管的流固耦合特性研究[J]. 推进技术, 2022, 43(10): 158–167. doi: 10.13675/j.cnki.tjjs.210349SUN P, ZHOU L, WANG Z X, et al. Fluid-structure interaction characteristic of double serpentine nozzle[J]. Journal of Propulsion Technology, 2022, 43(10): 158–167. doi: 10.13675/j.cnki.tjjs.210349 [18] 周莉, 孟钰博, 王占学. S弯收扩喷管流动特性数值研究[J]. 推进技术, 2021, 42(1): 103–113,2. doi: 10.13675/j.cnki.tjjs.200271ZHOU L, MENG Y B, WANG Z X. Numerical study on flow characteristics of serpentine convergent-divergent nozzle[J]. Journal of Propulsion Technology, 2021, 42(1): 103–113,2. doi: 10.13675/j.cnki.tjjs.200271 [19] 汪文杰, 王占学, 周莉, 等. 大涵道比短舱/排气系统耦合影响的数值研究[J]. 工程热物理学报, 2019, 40(9): 1981–1987.WANG W J, WANG Z X, ZHOU L, et al. A numerical simulation on the coupled influence of the high bypass ratio nacelle and exhaust system[J]. Journal of Engineering Thermophysics, 2019, 40(9): 1981–1987. [20] 张睿琳, 周莉, 王占学, 等. S弯喷管喷流噪声特性研究[J]. 推进技术, 2022, 43(7): 185–193. doi: 10.13675/j.cnki.tjjs.210049ZHANG R L, ZHOU L, WANG Z X, et al. Jet noise characteristics of S-shaped nozzle[J]. Journal of Propulsion Technology, 2022, 43(7): 185–193. doi: 10.13675/j.cnki.tjjs.210049 [21] 罗明东, 吉洪湖, 黄伟, 等. 无加力涡扇发动机二元喷管的红外辐射特性实验[J]. 航空动力学报, 2006, 21(4): 631–636. doi: 10.13224/j.cnki.jasp.2006.04.003LUO M D, JI H H, HUANG W, et al. An experimental investigation on infrared radiation characteristics of 2-D nozzles of turbofan engine afterburner[J]. Journal of Aero-space Power, 2006, 21(4): 631–636. doi: 10.13224/j.cnki.jasp.2006.04.003 [22] 额日其太, 王强, 陈渭鹏. 两种涡扇发动机排气系统红外辐射特性的比较[J]. 推进技术, 2003, 24(4): 334–336, 367. doi: 10.13675/j.cnki.tjjs.2003.04.013ERIQITAI, WANG Q, CHEN W P. Comparative investi-gation of the infrared characteristics for two exhaust systems of a turbofan engine[J]. Journal of Propulsion Technology, 2003, 24(4): 334–336, 367. doi: 10.13675/j.cnki.tjjs.2003.04.013 [23] 宫禹. 涡扇发动机排气系统红外隐身实验装置的总体设计及性能仿真研究[D]. 南京: 南京航空航天大学, 2007.GONG Y. Design and performance simulation of an experimental rig for infrared stealth research of exhaust system of a turbofan engine[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2007. [24] 是介, 周莉, 史经纬, 等. 三轴承矢量喷管红外辐射特性[J]. 航空动力学报, 2022, 37(6): 1195–1205. doi: 10.13224/j.cnki.jasp.20210268SHI J, ZHOU L, SHI J W, et al. Infrared radiation signature of three bearing swivel nozzle[J]. Journal of Aerospace Power, 2022, 37(6): 1195–1205. doi: 10.13224/j.cnki.jasp.20210268 [25] 蒋建峰, 征建生. 锯齿矢量喷管气动和红外辐射特性研究[J]. 激光与红外, 2022, 52(2): 234–239. doi: 10.3969/j.issn.1001-5078.2022.02.014JIANG J F, ZHENG J S. Research on aerodynamic and infrared signature of vectoring nozzle with chevron[J]. Laser & Infrared, 2022, 52(2): 234–239. doi: 10.3969/j.issn.1001-5078.2022.02.014 [26] 宋宇, 杨青真, 高翔, 等. 介质涂覆位置对二元塞式喷管的电磁散射特性影响[J]. 推进技术, 2022, 43(11): 161–168. doi: 10.13675/j.cnki.tjjs.210509SONG Y, YANG Q Z, GAO X, et al. Electromagnetic scattering characteristics of binary plug nozzle with coating medium at different part[J]. Journal of Propulsion Techno-logy, 2022, 43(11): 161–168. doi: 10.13675/j.cnki.tjjs.210509 [27] 高翔, 高扬, 朱彦伟. 某型混合排气涡扇发动机喷管特性计算方法研究[J]. 机械研究与应用, 2017, 30(1): 1–4. doi: 10.16576/j.cnki.1007-4414.2017.01.001GAO X, GAO Y, ZHU Y W. Study on nozzle characteristics computation method of a mixed exhaust turbofan engine[J]. Mechanical Research & Application, 2017, 30(1): 1–4. doi: 10.16576/j.cnki.1007-4414.2017.01.001 [28] 高翔, 高扬, 李密. 基于响应面法的混合排气涡扇发动机喷管特性研究[J]. 航空科学技术, 2016, 27(11): 19–24. doi: 10.3969/j.issn.1007-5453.2016.11.004GAO X, GAO Y, LI M. Research on nozzle characteristics of a mixed exhaust turbofan engine based on response surface methodology[J]. Aeronautical Science & Technology, 2016, 27(11): 19–24. doi: 10.3969/j.issn.1007-5453.2016.11.004 [29] 邵万仁. 基于数值模拟的轴对称矢量喷管内流特性研究[J]. 航空动力学报, 2008, 23(5): 52–59. doi: 110.13224/j.cnki.jasp.2008.05.009SHAO W R. Study of internal performance for an axisym-metric vectoring exhaust nozzle using numerical simulation[J]. Journal of Aerospace Power, 2008, 23(5): 52–59. doi: 110.13224/j.cnki.jasp.2008.05.009 [30] 李秋锋, 李密, 王定奇. 测量耙对小尺寸发动机性能影响的研究[J]. 测控技术, 2022, 41(3): 38–43. doi: 10.19708/j.ckjs.2022.03.007LI Q F, LI M, WANG D Q. Research on the effect of measuring rake on performance of the small-size engine[J]. Measurement & Control Technology, 2022, 41(3): 38–43. doi: 10.19708/j.ckjs.2022.03.007 [31] 李宁. 二元矢量喷管气动特性数值模拟[C]//北京力学会第二十三届学术年会会议论文集. 2017: 147–150. [32] 王殿磊, 叶留增, 汪东, 等. 不同宽高比的二元收–扩喷管内流特性数值研究[C]//探索 创新 交流(第7集)——第七届中国航空学会青年科技论坛文集(上册). 2016: 365–369. [33] 白伟, 高为民, 任智博, 等. 喷管面积比对推力矢量发动机特性的影响[J]. 航空动力学报, 2021, 36(7): 1426–1433. doi: 10.13224/j.cnki.jasp.20210129BAI W, GAO W M, REN Z B, et al. Influences of nozzle area ratio on thrust vector engine characteristic[J]. Journal of Aerospace Power, 2021, 36(7): 1426–1433. doi: 10.13224/j.cnki.jasp.20210129 [34] 汤伟, 刘李涛, 陈洪, 等. 矢量喷管推力特性的风洞试验技术[J]. 航空动力学报, 2018, 33(4): 858–864. doi: 10.13224/j.cnki.jasp.2018.04.011TANG W, LIU L T, CHEN H, et al. Thrust characteristics test technique of vectoring nozzle in wind tunnel[J]. Journal of Aerospace Power, 2018, 33(4): 858–864. doi: 10.13224/j.cnki.jasp.2018.04.011 [35] 陈雪冬, 唐贵明, 王发民. 用于脉冲风洞的热喷流实验方法初步研究[C]//第八届全国实验流体力学学术会议论文集. 2010: 195–204. [36] B. A. 索苏诺夫, B. M. 切普金. 航空发动机和动力装置的原理、计算及设计[Z]. 莫斯科国立航空学院, 2003: 424–423. [37] 史经纬. 固定几何气动矢量喷管流动机理及性能评估技术研究[D]. 西安: 西北工业大学, 2015.SHI J W. Investigation on flow mechanism and performance estimation of fixed-geometric thrust vectoring nozzle[D]. Xi'an: Northwestern Polytechnical University, 2015. [38] ABERNETHY R B, ADAMS G R, ASCOUGH J C, et al. In-flight thrust determination[R]. SAE AIR 1703, 1986: 48–54. [39] 廉筱纯, 吴虎. 航空发动机原理[M]. 西安: 西北工业大学出版社, 2005: 16–17. [40] 李秋锋, 李密, 高翔. 测量耙对尾喷管内流流场性能参数的影响[J]. 现代机械, 2017(6): 29–33. doi: 10.13667/j.cnki.52-1046/th.2017.06.008LI Q F, LI M, GAO X. Influence of measurement rake on performance parameters of internal flow field in nozzle[J]. Modern Machinery, 2017(6): 29–33. doi: 10.13667/j.cnki.52-1046/th.2017.06.008 [41] 高扬. ARJ21–700飞机飞行推力确定(IFTD)技术论文[G]. 中国飞行试验研究院, 2011. [42] 战培国. 美国AIAA风洞试验不确定度评定标准研究[J]. 标准科学, 2014(1): 68–71.ZHAN P G. Research on American AIAA standard of assessment uncertainty for wind tunnel testing[J]. Standard Science, 2014(1): 68–71. [43] 朱新新, 隆永胜, 赵顺洪, 等. 基于总温探针的高精度总焓测量方法优化研究[J]. 实验流体力学, doi: 10.11729/syltlx20210149.ZHU X X, LONG Y S, ZHAO S H, et al. Optimization of total enthalpy measurement method based on the total temperature probe[J]. Journal of Experiments in Fluid Mechanics, doi: 10.11729/syltlx20210149. [44] ABERNETHY R B, ADAMS G R, STEURER J W. Uncertainty of in-flight thrust determination[R]. SAE AIR 1678, 1986: 23–26. -

下载:

下载: