| [1] |

朱延鑫, 谭晓茗, 郭文, 等.出流孔型对平板气膜冷却影响机理的研究[J].推进技术, 2013, 34(4):499-505. http://d.old.wanfangdata.com.cn/Periodical/tjjs201304011Zhu Y X, Tan X M, Guo W, et al. Numerical simulation on effects of different film cooling holes on plat[J]. Journal of Propulsion Technology, 2013, 34(4):499-505. http://d.old.wanfangdata.com.cn/Periodical/tjjs201304011

|

| [2] |

葛绍岩, 徐靖中.气膜冷却[M].北京:科学出版社, 1985.Ge S Y, Xu J Z. Film cooling[M]. Beijing:Science Press, 1985.

|

| [3] |

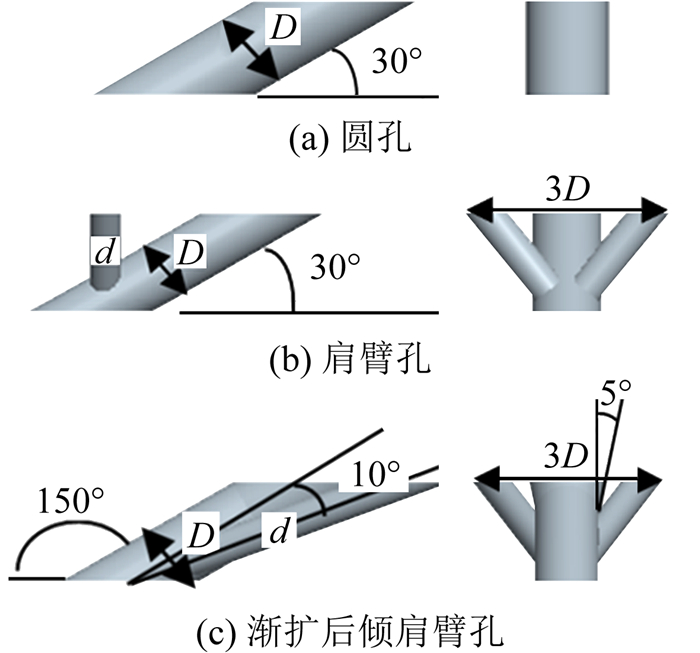

李少华, 宋东辉, 刘建红, 等.不同孔型平板气膜冷却的数值模拟[J].中国电机工程学报, 2006, 26(17):112-116. doi: 10.3321/j.issn:0258-8013.2006.17.020Li S H, Song D H, Liu J H, et al. Numerical simulations of flat plate film cooling using respectively different shaped jet holes[J]. Proceedings of the CSEE, 2006, 26(17):112-116. doi: 10.3321/j.issn:0258-8013.2006.17.020

|

| [4] |

Leylek J H, Zerkle R D. Discrete jet film-cooling:a comparison of computational results with experiments[J]. ASME Journal of Transaction, 1994, 116(3):358-368.

|

| [5] |

Goldstein R J, Eckert E R, Burggraf F. Effects of hole geometry and density on three-dimensional film cooling[J]. International Journal of Heat & Mass Transfer, 1974, 17(5):595-607.

|

| [6] |

Okita Y, Nishiura M. Film effectiveness performance of an arrow head-shaped film-cooling hole geometry[J]. Journal of Turbomachinery, 2007, 129(2):331-339. doi: 10.1115/1.2437781

|

| [7] |

Kusterer K, Bohn D, Sugimoto T, et al. Double-jet ejection of cooling air for improved film cooling[J]. Journal of Turboma-chinery, 2007, 129(4); 809-815. doi: 10.1115/1.2720508

|

| [8] |

Heidmann J D, Ekkad S. A novel antivortex turbine film-cooling hole concept[J]. Journal of Turbomachinery, 2008, 130(3):031020. doi: 10.1115/1.2777194

|

| [9] |

Mhetras S, Yang H T, Gao Z H, et al. Film-cooling effectiveness on squealer rim walls and squealer cavity floor of a gas turbine blade tip using pressure sensitive paint[R]. GT2005-68387, 2005.

|

| [10] |

Suryanarayanan A, Mhetras S P, Schobeiri M T, et al. Film-cooling effectiveness on a rotating blade platform[J]. Journal of Turbomachinery, 2009, 131(1):011014. doi: 10.1115/1.2752184

|

| [11] |

Gao Z H, Wright L M, Han J. Assessment of steady state PSP and transient ir measurement techniques for leading edge film cooling[C]//Proc of ASME 2005 International Mechanical Engineering Congress and Expositon. 2005.

|

| [12] |

Shadid J N, Eckert E R G. The mass transfer to heat transfer in fluids with temperature-dependent properties[J]. Journal of Turbomachinery, 1991, 113(1):27-33. doi: 10.1115/1.2927734

|

| [13] |

Caciolli G, Facchini B, Picchi A, et al. Comparison between PSP and TLC steady state techniques for adiabatic effectiveness measurement on a multiperforated plate[J]. Experimental Thermal and Fluid Science, 2013, 48:122-133. doi: 10.1016/j.expthermflusci.2013.02.015

|

| [14] |

Jones T V. Theory for the use of foreign gas in simulating film cooling[J]. International Journal of Heat & Fluid Flow, 1999, 20:349-354. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=2bb9574e2809f39f5fb4ddd510c7ed46

|

| [15] |

Yang Z F, Hu H. An experimental investigation on the trailing edge cooling of turbine blades by using PIV and PSP techniques[J]. Propulsion & Power Research, 2012, 1(1):36-47. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=CC0212472186

|

| [16] |

Ekkad S V, Zapata D, Han J C. Film Effectiveness over a flat surface with air and CO2 injection through compound angle holes using a transient liquid crystal image method[J]. Journal of Turbomachinery, 1997, 119(3):587-593. doi: 10.1115/1.2841162

|

| [17] |

Saumweber C, Schulz A, Wittig S. Free-stream turbulence effects on film cooling with shaped holes[J]. Journal of Turbomachinery, 2003, 125(1):65-73. doi: 10.1115/1.1515336

|

| [18] |

Gustafson R, Mahmood G I, Acharya S. Flowfield in a film-cooled three-dimensional endwall passage: aerodynamic mea-surements[C]. ASME Paper 2007, No. GT2007-28154.

|

| [19] |

Bunker R S. A review of shaped hole turbine film-cooling technology[J]. Journal of Heat Transfer Transactions of the ASME, 2005, 127(4):441-453. doi: 10.1115/1.1860562

|

| [20] |

Ekkad S V, Ou S, Rivir R B. Effect of jet pulsation and duty cycle on film cooling from a single jet on a leading edge model[J]. Journal of Turbomachinery, 2006, 128(3):564-571. doi: 10.1115/1.2185122

|

| [21] |

Bogard D G, Thole K A. Gas turbine film cooling[J]. Journal of Propulsion & Power, 2005, 22(2):249-270. http://d.old.wanfangdata.com.cn/Periodical/zgdjgcxb201129016

|

| [22] |

Sinha A K, Bogard D, Crawford M E. Film-cooling effectiveness downstream of a single row of holes with variable density ratio[J]. Journal of Turbomachinery, 1991, 113(3):441-449. doi: 10.1115-1.2927894/

|

| [23] |

李佳, 韩昌, 任静, 等.基于压敏漆的带横槽气膜冷却实验与数值研究[J].工程热物理学报, 2010, 31(2):239-242. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201000068855Li J, Han C, Ren J, et al. Film cooling performance of the embedded holes in trenches with compound angles[J]. Journal of Engineering Thermophysics, 2010, 31(2):239-242. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201000068855

|

| [24] |

Kapadia S, Roy S, Heidmann J. First hybrid turbulence modeling for turbine blade cooling[J]. Journal of Thermophysics & Heat Transfer, 2015, 18(1):154-156. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=1223dac0471065d9431efadde430a255

|

| [25] |

Bunker R S. Film cooling effectiveness due to discrete holes within a transverse surface slot[C]//Proc of ASME Turbo Expo 2002: Power for Land, Sea, and Air. 2002.

|

下载:

下载: