Measurements on compressor dynamic total pressure with dynamic correction of pneumatic probe

-

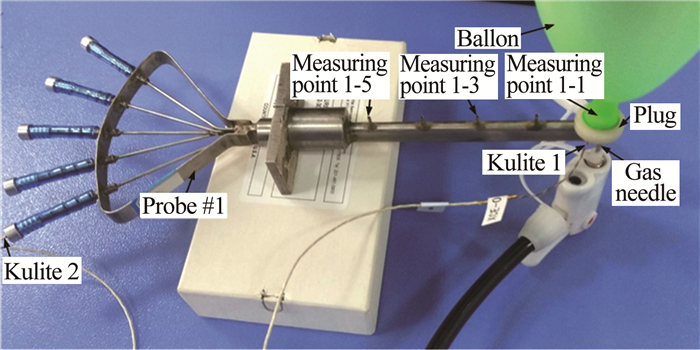

摘要: 为方便安全地获取压气机内部多点动态总压信号,采用气动探针将测点压力引出,并通过动态修正还原测点处的压力信号。利用爆破气球装置产生的向下阶跃输入信号和探针响应输出信号,辨识得到探针管路的离散传递函数模型,以此来修正测量信号,获得测点真实压力。所用标定方法能够实现1000Hz以内信号的动态修正,探针信号经过修正后能够消除相位延迟,且管路谐振效应对信号的放大作用显著减小。压气机动态总压测试结果表明:随着进气流量的减小,转子进口叶片通过频率信号幅值逐渐增大,静子出口宽频扰动增强,在近失速点宽频扰动最大;压气机突尖型旋转失速先兆首先出现在转子叶片前缘叶顶附近,而后向叶根方向迅速扩展,并形成全叶高范围的旋转失速团,完全发展的失速团传播速度约为30%转子转速。Abstract: The pressure signals at measurement points are extracted via pneumatic probes and restored by dynamic correction in order to obtain the multi-point dynamic total pressures in the compressor conveniently and safely. The discrete transfer function models are used to correct the measured signals and obtain the real pressures at the measurement points. These models are identified by the downward step input signals and probe response output signals generated by the burst balloon device. It is proved that the method is reliable for the signal dynamic correction within 1000Hz, the phase delay can be eliminated virtually and the tube resonance effect on the signal amplification can be reduced obviously after correction of the probe signal. The measurement results of dynamic total pressure in compressor show that the signal amplitude of blade passing frequency at rotor inlet increases gradually with the decrease of mass flow rate, meanwhile, the broadband disturbance intensity at stator outlet increases and reaches the maximum at the near rotating stall point. In addition, the spike-type rotating stall inception first appears near the tip of the rotor blade leading edge, then expands rapidly to the blade root and develops into a full-span rotating stall cell. The propagation speed of the fully developed stall cell is about 30% of the rotor rotating speed.

-

Key words:

- compressor /

- pneumatic probe /

- transfer function /

- dynamic correction /

- rotating stall /

- spike

-

表 1 压气机设计参数

Table 1. Design parameters of tested compressor

Parameters Value Outer diameter/mm 1400 Rotational speed/(r·min-1) 3600 Mass flow rate/(kg·s-1) 65 Total pressure ratio 1.2 Hub-tip ratio 0.824 Rotor tip clearance/mm 1.5 IGV/Rotor/Stator blade numbers 35/37/67 -

[1] Javed A, Arpagaus C, Bertsch S, et al. Small-scale turbocompressors for wide-range operation with large tip-clearances for a two-stage heat pump concept[J]. International Journal of Refrigeration, 2016, 69:285-302. doi: 10.1016/j.ijrefrig.2016.06.015 [2] Brouckaert J F. Fast response aerodynamic probes for measurements in turbomachines[J]. Proceedings of the Institution of Mechanical Engineers, Part A:Journal of Power and Energy, 2007, 221(6):811-813. doi: 10.1243/09576509JPE460 [3] 高永卫, 黄鹏, 朱奇亮, 等.采用长细管法进行脉动压力转捩探测的实验研究[J].实验流体力学, 2014, 28(6):98-103. http://www.syltlx.com/CN/abstract/abstract10797.shtmlGao Y W, Huang P, Zhu Q L, et al. Experimental study on pressure fluctuation sensor-based diagnostic for boundary layer transition with long-fine tubing system[J]. Journal of Experiments in Fluid Mechanics, 2014, 28(6):98-103. http://www.syltlx.com/CN/abstract/abstract10797.shtml [4] Shalash K, Şahin F C, Schiffmann J. Non-linear transfer function identification of pressure probes using Siren Disks[J]. Experimental Thermal and Fluid Science, 2018, 91:459-469. doi: 10.1016/j.expthermflusci.2017.11.001 [5] Stecki J S, Davis D C. Fluid transmission lines-distributed parameter models part 1:A review of the state of the art[J]. Proceedings of the Institution of Mechanical Engineers, Part A:Journal of Power and Energy, 1986, 200(4):215-228. doi: 10.1243/PIME_PROC_1986_200_032_02 [6] Bergh H, Tijdeman H. Theoretical and experimental results for the dynamic response of pressure measuring systems[R]. NLR-TR F.238, 1965. [7] Grimshaw S D, Taylor J V. Fast settling millimetre-scale five-hole probes[R]. ASME GT-2016-56628, 2016. [8] 马文勇, 刘庆宽, 刘小兵, 等.风洞试验中测压管路信号畸变及修正研究[J].实验流体力学, 2013, 27(4):71-77. doi: 10.3969/j.issn.1672-9897.2013.04.013Ma W Y, Liu Q K, Liu X B, et al. Study on correction and distortion effects caused by tubing systems of pressure measure-ments in wind tunnel[J]. Journal of Experiments in Fluid Mechanics, 2013, 27(4):71-77. doi: 10.3969/j.issn.1672-9897.2013.04.013 [9] Paniagua G, Dénos R. Digital compensation of pressure sensors in the time domain[J]. Experiments in fluids, 2002, 32(4):417-424. doi: 10.1007/s003480100355 [10] 杨慧, 西姆斯-威廉姆斯·戴维, 何力.非定常压力测量中信号失真的管传递函数修正方法[J].实验流体力学, 2007, 21(1):70-75. http://www.syltlx.com/CN/abstract/abstract9573.shtmlYang H, Sims-Williams D B, He L. Tubing-transfer-function correction on signal distortion for unsteadypressure measurements[J]. Journal of Experiments in Fluid Mechanics, 2007, 21(1):70-75. http://www.syltlx.com/CN/abstract/abstract9573.shtml [11] 叶挺, 梁庭, 张文栋.压力测试中引压管的动态特性研究[J].中北大学学报(自然科学版), 2011, 32(2):222-226. doi: 10.3969/j.issn.1673-3193.2011.02.021Ye T, Liang T, Zhang W D. Dynamic characteristic of transmission tube in pressure measurement system[J]. Journal of North University of China:Natural Science Edition, 2011, 32(2):222-226. doi: 10.3969/j.issn.1673-3193.2011.02.021 [12] Kobata T, Ooiwa A. Method of evaluating frequency characteristics of pressure transducers using newly developed dynamic pressure generator[J]. Sensors and Actuators A:Physical, 2000, 79(2):97-101. doi: 10.1016/S0924-4247(99)00271-X [13] Diniz A, Oliveira A B S, Vianna J, et al. Dynamic calibration methods for pressure sensors and development of standard devices for dynamic pressure[C]//Proc of XVⅢ Imeko World Congress Metrology for a Sustainable Development. 2006. [14] Persico G, Gaetani P, Guardone A. Dynamic calibration of fast-response probes in low-pressure shock tubes[J]. Measurement Science and Technology, 2005, 16(9):1751-1759. doi: 10.1088/0957-0233/16/9/006 [15] 李继超, 王偲臣, 林峰, 等.一种容腔效应标定技术及其在高频响动态探针中的应用[J].航空动力学报, 2011, 26(12):2749-2756. http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201112019Li J C, Wang S C, Lin F, et al. A technique to calibrate cavity effect in unsteady pressure probes with high frequency response[J]. Journal of Aerospace Power, 2011, 26(12):2749-2756. http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201112019 [16] 杨林, 王偲臣, 林峰, 等.基于半无限引压管效应的动态压力测量方法[J].航空动力学报, 2014, 29(10):2457-2463. http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201410024Yang L, Wang S C, Lin F, et al. Method of dynamic pressure measurement based on semi-infinite pressure tube effect[J]. Journal of Aerospace Power, 2014, 29(10):2457-2463. http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201410024 [17] 马宏伟, 魏巍, 张良, 等.欠频响压力探针测量压气机动态流场的结果分析[J].航空发动机, 2016, 42(2):67-72. http://d.old.wanfangdata.com.cn/Periodical/hkfdj201602013Ma H W, Wei W, Zhang L, et al. Analysis of measured unsteady flow field using a quasi fast response pressure probe[J]. Aeroengine, 2016, 42(2):67-72. http://d.old.wanfangdata.com.cn/Periodical/hkfdj201602013 [18] 陈峰, 时培杰, 刘东健, 等.周向畸变进气下压气机动态失速特性研究[J].推进技术, 2018, 39(6):1283-1292. http://d.old.wanfangdata.com.cn/Periodical/tjjs201806011Chen F, Shi P J, Liu D J, et al. Investigation on compressor dynamic stall characteristics with circumferential inlet distortion[J]. Journal of Propulsion Technology, 2018, 39(6):1283-1292. http://d.old.wanfangdata.com.cn/Periodical/tjjs201806011 -

下载:

下载: