The validity analysis of ground simulation test for non-ablative thermal protection materials

-

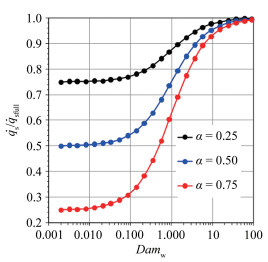

摘要: 流场化学非平衡度与材料表面催化反应的耦合控制着服役于化学非平衡流场中非烧蚀防热材料表面的气动热载荷,若在该类防热材料性能模拟研究中忽略这一耦合效应,地面模拟试验将无法获得材料的有效使用性能。为此,本文依据钝头体高超声速飞行器边界层驻点热流关系式,分析了影响驻点热流的主要流场参数、地面高焓模拟设备所提供的高焓超声速流场特点以及与飞行热环境之间的主要差异,采用CFD分析了"三参数"模拟方法的有效性。针对化学非平衡边界层驻点传热分析,提出"四参数"模拟方法并分析了"四参数"模拟方法中离解焓无法模拟时的防热材料性能并提出初步解决方法。Abstract: The aerodynamic heat load on the surface of the non-ablative thermal protection materials which served in the chemical non-equilibrium flow field, is controlled by the coupling of chemical non-equilibrium degree of flow field and the surface catalytic reaction of the materials. If the coupled effect is neglected in the performance simulation, the effective service performance cannot be obtained through the ground simulation test. Therefore, according to the stagnation-point heat flux relationship within the boundary layer of the blunt body supersonic vehicle, the present paper analyzes the principal flow field parameters, the characteristics of high-enthalpy supersonic field provided by ground simulation equipment, and the differences between ground and flight environments. The validity of the Three-Parameter-Simulation method is analyzed by the CFD simulation. A Four-Parameter-Simulation method is presented for analyzing the heat transfer of the chemical non-equilibrium stagnation-point boundary layer. Besides, the properties of the thermal protection materials is analyzed and a preliminary solution is proposed when the dissociation enthalpy in the Four-Parameter-Simulation is unable to be simulated.

-

表 1 The states of supersonic flow fields in arc-heated wind tunnels for calculation

Table 1. The states of supersonic flow fields in arc-heated wind tunnels for calculation

AHWT In-chamber pressure/kPa 180.0 In-chamber enthalpy/(kJ·kg-1) 2.3×104 Nozzle throat/mm Φ30.0 Nozzle outlet/mm Φ200.0 表 2 The flight conditions

Table 2. The flight conditions

RnF/mm U∞F/(m·s-1) p∞F/Pa T∞F/K CFO2 CFN2 COF CNF CNOF Case 1

Case 2200

356930 8 229.5 0.234 0.766 0 0 0 表 3 The AHWT simulation conditions

Table 3. The AHWT simulation conditions

RnS/mm U∞S(m·s-1) p∞S/Pa T∞S/K CSO2 CSN2 COS CNS CNOS Case 1 35 4654 107 920 0 0.508 0.234 0.258 0 表 4 The stagnation-point heat flux & pressure for flight environment

Table 4. The stagnation-point heat flux & pressure for flight environment

RnF/mm pFs/Pa Heat flux of full surface catalysis /(kW·m-2) Heat flux of non surface catalysis /(kW·m-2)

Case 1 200 5540 1096 830 1926 1089 0 1089 0.565 Case 2 35 5540 3247 1531 4778 3176 50 3176 0.665 表 5 The stagnation-point heat flux & pressure for simulated environment

Table 5. The stagnation-point heat flux & pressure for simulated environment

RnF/mm psF/Pa Heat flux of full surface catalysis /(kW·m-2) Heat flux of non surface catalysis /(kW·m-2)

Case 1 35.00 5500 1118 834 1952 1120 0 1120 0.574 Case 2 26.65 5500 2483 2391 4874 2229 0 2229 0.457 表 6 The compared of conduction & diffussion stagnation-point heat flux between flight and simulated environment

Table 6. The compared of conduction & diffussion stagnation-point heat flux between flight and simulated environment

Case 1 2.01% 0.482% 1.35% 2.85% 2.85% Case 2 -23.53% 56.17% 2.01% -29.82% -29.82% -

[1] Matthew M, Eric M, Ronald P. Effect of surface catalysis on measured heat transfer in expansion tunnel facility[R]. AIAA-2012-0651, 2012. [2] Kurotaki T. Construction of catalytic model on SiO2-based surface and application to real trajectory[R]. AIAA-2000-2366, 2000. [3] Voinov L, Zalogin G N, Lunev V V, et al. Comparative analysis of laboratory and full-scale data on the catalycity of the heat shield for the Bor and Buran orbital vehicles[J]. Cosmonautics and Rocket Production. 1994(2): 51-57. http://www.sciencedirect.com/science/article/pii/0966979594900515 [4] Kolodziej P, Stewart D A. Nitrogen recombination on high-temperature reusable surface insulation and the analysis of its effect on surface catalysis[R]. AIAA-1987-1637, 1987. [5] Scott C D. Catalytic recombination of nitrogen and oxygen on hig-temperature reusable surface insulation[R]. AIAA-1980-1477, 1980. [6] Stewart D A, Rakich J V, Lanfranco M J. Catalytic surface effects experiments on space shuttle[R]. AIAA-1981-1143, 1981. [7] Rakich J V, Stewart D A, Lanfranco M J. Results of a flight experiment of the catalytic efficiency of the space shuttle heat shield[R]. AIAA-1982-944, 1982. [8] Zoby E V, Gupta R N, Simmonds A L. Temperature dependent reaction-rate expression for oxygen recombination at shuttle entry conditions[R]. AIAA-1984-224, 1984. [9] Shim J L, Moss J N, Simmonds A L. Viscous-shock-layer heating analysis for the shuttle windward symmetry plane with surface finite catalytic recombination rates[R]. AIAA-1982-0842, 1982. [10] Jumper E J. Recombination of oxygen and nitrogen on silica-based thermal protection surfaces: mechanism and implication[R]. AIAA-1993-477, 1993. [11] Melin G A, Madix R J. Energy accommodation during oxygen atom recombination on metal surface[J]. Transactions of the Faraday Society, 1971, 67: 198-211. doi: 10.1039/tf9716700198 [12] Halpern B, Rosner D E. Chemical energy accommodation at catalyst surface. Flow reactor studies of the association of nitrogen atoms on metals at high temperatures[J]. Journal of the Chemical Society Faraday Transactions, 1978, 74: 1883-1912. doi: 10.1039/f19787401883 [13] Kolesnikov A F. The concept of local simulation for stagnation point heat transfer in hypersonic flow: applications and validation[R]. AIAA-2000-2515, 2000. [14] Kovalev V L, Kolesnikov A F. Experimental and theoretical simulation of heterogeneous catalysis in aerothermochemistry(a review)[J]. Fluid Dynamics, 2005, 40(5): 669-693. doi: 10.1007/s10697-005-0106-4 [15] Fay J A, Riddell F R. Theory of stagnation point heat transfer in dissociated air[J]. Journal of the Aeronautical Sciences, 1958, 25(2): 73-85. http://www.ams.org/mathscinet-getitem?mr=94043 [16] Goulard R. On catalytic recombination rates in hypersonic stagnation on heat transfer[J]. Journal of Jet Propulsion, 1958, 28(11): 737-745. doi: 10.2514/8.7444 -

下载:

下载: