Investigation on target jet mill based on the entrainment of the annular supersonic flow

-

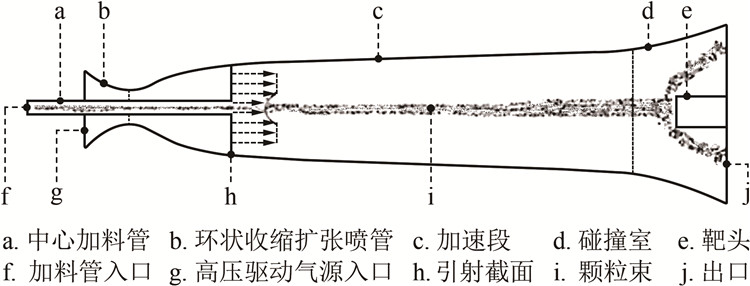

摘要: 气流磨作为生产超精细粉末的设备在工业界得到了广泛应用。通过数值模拟和试验验证,提出了一种超声速靶式气流磨。该气流磨采用环状超声速气流引射颗粒流,使其达到超声速状态并获得极大动能,以颗粒束形式维持于气流中心,准确碰撞靶头,实现超声速粉碎。对颗粒速度和运动轨迹的两相流数值模拟结果表明:在总压1.5 MPa、马赫数3.0的超声速气流引射作用下,粒径为25~1 μm的颗粒可加速至440~530 m/s,并精准地碰撞靶头。在此基础上,设计制造了超声速靶式气流磨并进行了铁粉粉碎试验和靶头侵蚀试验,结果表明:颗粒具有极大的碰撞能量,且与靶头发生了聚焦式碰撞。Abstract: The jet mill widely used in many industrial fields is a kind of apparatus to produce superfine powder. A new supersonic jet mill, whose design is based on numerical simulations and collision experiments, is presented and manufactured. In our design an annular supersonic flow produced by an annular converging-diverging nozzle is used to entrain the central subsonic flow with particles. After the supersonic flow's entrainment, the particle beam concentrated in the flow center impacts on the target accurately with a great kinetic energy. The multiphase numerical studies show that the collision speed of particles of 25 μm to 1 μm in diameter can reach 440 m/s to 530 m/s approximately in the entrainment of the supersonic flow with the Mach number of 3.0 and the total pressure of 1.5 MPa, and particles can precisely collide on the target. The collision experiments implemented in the new-made jet mill manifest the huge collision energy and the precise supersonic collision in the jet mill by the target erosion and the iron particles size reduction.

-

Key words:

- target jet mill /

- supersonic annular flow /

- entrainment /

- supersonic collision /

- multi-phases flow

-

表 1 超声速气流磨的参数

Table 1. The parameters of supersonic jet mill

几何参数 热力学参数 动力学参数 环状喷管 Athr=15.7 mm2

Aex=66.5 mm2p0=1.5 MPa

T0=300 K

pex=40.8 kPa

Tex=107 KMa=3.0

uex=622 m/s

加料管 A=7.07 mm2

L=0.1 mpatm=0.1 MPa

Tatm=300 Kuex=317 m/s

加速段 L=0.4 m

Φin=10.02 mm

Φex=14.00 mm碰撞室 β=3° pout=0.1 MPa

T0,out=300 K靶头 Φ=4.00 mm 壁面 χ=0.03 表 2 超声速气流磨流场验证试验结果

Table 2. The validation test of the jet mill supersonic field

p0 /MPa p/MPa Ma v/(m·s-1) Kinetic energy/(J·g-1) 0.5 0.091 1.77 481 115 1.0 0.082 2.29 555 154 1.5 0.058 2.77 604 182 2.0 0.053 3.02 623 194 表 3 铁粉的统计粒径

Table 3. The statistic radius of iron particles size distributions

d10/μm d50/μm d90/μm Before 28.2 64.3 150.8 After 2.6 7.8 29.9 -

[1] BERTHIAUX H, DODDS J. Modelling fine grinding in a fluidized bed opposed jet mill: Part I: Batch grinding kinetics[J]. Powder Technology, 1999, 106(1-2): 78-87. doi: 10.1016/S0032-5910(99)00049-2 [2] MIDOUX N, HOŠEK P, PAILLERES L, et al. Micronization of pharmaceutical substances in a spiral jet mill[J]. Powder Technology, 1999, 104(2): 113-120. doi: 10.1016/S0032-5910(99)00052-2 [3] HIROAKI M, KO H, HIDETO Y. Powder technology handbook[M]. 3rd ed. Boca Raton: CRC Press, 2006. [4] TASIRIN S M, GELDART D. Experimental investigation on fluidized bed jet grinding[J]. Powder Technology, 1999, 105(1-3): 337-341. doi: 10.1016/S0032-5910(99)00156-4 [5] NAKACH M, AUTHELIN J R, CHAMAYOU A, et al. Comparison of various milling technologies for grinding pharmaceutical powders[J]. International Journal of Mineral Processing, 2004, 74(S): S173-S181. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=80f601f866356b302780bebdf0ba9d85 [6] CHAMAYOU A, DODDS J A. Air jet milling[M]//Salman A D, Ghadiri M, Hounslow M J. Handbook of Powder Technology: vol 12. Amsterdam: Elsevier, 2007: 421-435. [7] GHAMBARI M, SHAIBANI M E, ESHRAGHI N. Produc-tion of grey cast iron powder via target jet milling[J]. Powder Technology, 2012, 221: 318-324. doi: 10.1016/j.powtec.2012.01.020 [8] LEVY A, KALMAN H. Numerical study of particle motion in jet milling[J]. Particulate Science and Technology, 2007, 25(2): 197-204. doi: 10.1080/02726350701257618 [9] RAJESWARI M S R, AZIZLI K A M, HASHIM S F S. CFD simulation and experimental analysis of flow dynamics and grinding performance of opposed fluidized bed air jet mill[J]. International Journal of Mineral Processing, 2011, 98(1-2): 94-105. doi: 10.1016/j.minpro.2010.10.012 [10] RODNIANSKI V, KRAKAUER N, DARWESH K, et al. Aerodynamic classification in a spiral jet mill[J]. Powder Technology, 2013, 243: 110-119. doi: 10.1016/j.powtec.2013.03.018 [11] ESKIN D, VOROPAYEV S, VASILKOV O. Simulation of jet milling[J]. Powder Technology, 1999, 105(1-3): 257-265. doi: 10.1016/S0032-5910(99)00146-1 [12] DOGBE S, GHADIRI M, HASSANPOUR A, et al. Fluid-particle energy transfer in spiral jet mill[J]. Powders and Grains, 2017, 140: 09040. https://www.researchgate.net/publication/318070564_Fluid-particle_energy_transfer_in_spiral_jet_milling [13] WHITE F M. Fluid mechanics[M]. 4th ed. New York: McGraw-Hill Press, 2005. [14] SAFFMAN P G. The lift on a small sphere in a slow shear flow[J]. Journal of Fluid Mechanics, 1965, 22(2): 385-400. doi: 10.1017/S0022112065000824 [15] WU W J, GIESE R F J, VAN OSS C J. Change in surface properties of solids caused by grinding[J]. Powder Technology, 1996, 89(2): 129-132. doi: 10.1016/S0032-5910(96)03158-0 [16] XIAO Z L, CHEN Q Y, YIN Z L, et al. Calorimetric investigation of mechanically activated storage energy mechanism of sphalerite and pyrite[J]. Thermochimica Acta, 2005, 436(1-2): 10-14. doi: 10.1016/j.tca.2005.06.042 [17] CROWE C T. Review-numerical models for dilute gas-particle flows[J]. Journal of Fluids Engineering, 1982, 104(3): 297-303. doi: 10.1115/1.3241835 [18] ZHOU L X. Theory and numerical modeling of turbulent gas-particles flows and combustion[M]. Beijing: Science press and Florida: CRC press, 1993. -

下载:

下载: