Experimental and theoretical model study on effective thermal conductivity of SOFC porous electrode

-

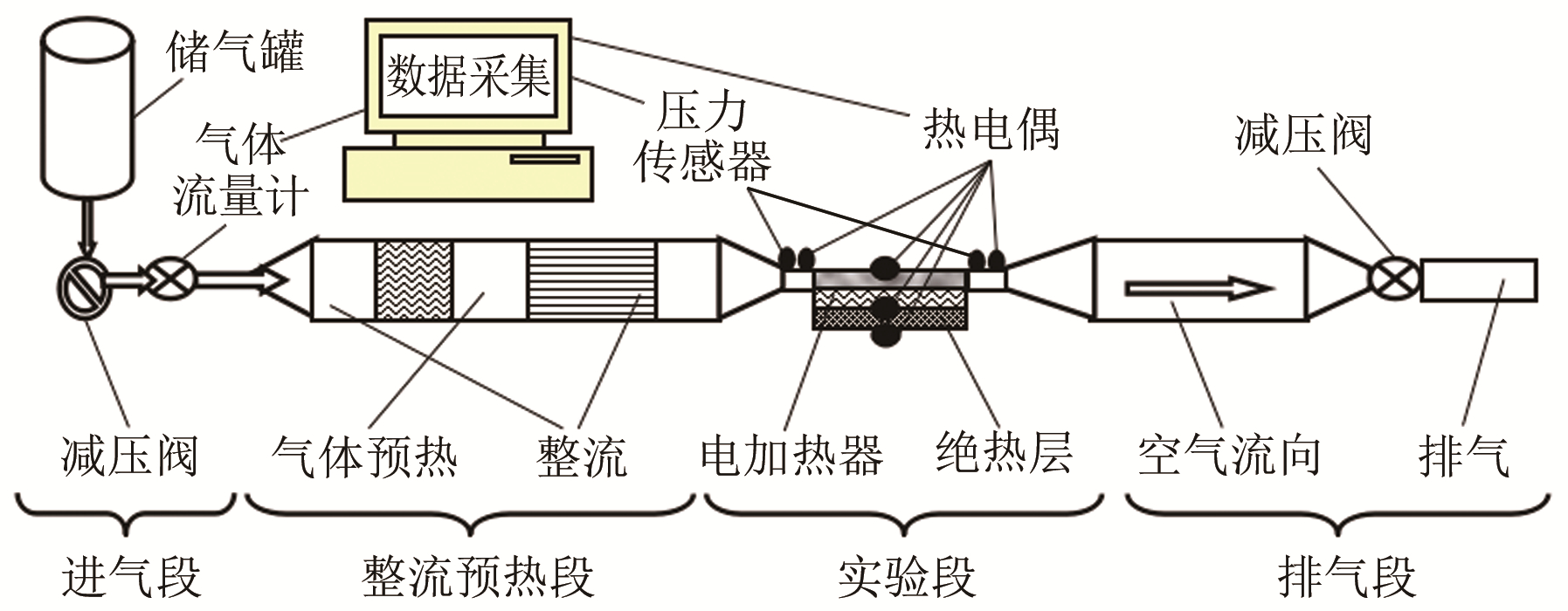

摘要: 固体氧化物燃料电池(SOFC)内部流动传热和化学反应复杂,容易产生热不平衡区。获取高精度的多孔电极有效导热系数对于建立多物理场耦合数值分析模型和电池热管理具有重要的意义。基于稳态法设计并搭建了多孔材料有效导热系统实验平台和测量系统,在372.1~932.4 K温度范围内详细测量了多孔电极实验样件温度分布,通过多孔材料内传热理论分析,基于现有EMT和ME1数学模型,利用比例因子t构造了温度修正的SOFC多孔电极综合有效导热系数的计算模型。同时通过对比孔隙率为0.2349~0.4178的3个实验样件表面温度的计算值和实验测量值,验证了该有效导热系数模型的有效性和高精度。Abstract: The flow heat transfer and chemical reaction inside the Solid Oxide Fuel Cell (SOFC) are complex, and it is easy to generate thermal imbalance zones. Obtaining high-precision effective thermal conductivity of porous electrodes is of great significance for the establishment of numerical analysis models of multi-physics field coupling and the thermal management. In this paper, an experimental platform and measurement system for the effective heat conduction system of porous materials was designed and constructed, which is based on the steady-state method. The temperature distribution of the porous electrode test specimens was measured in detail in the temperature range of 372.1~932.4K. Through the theoretical analysis of heat transfer in porous materials, the calculation model of the comprehensive effective thermal conductivity of temperature-corrected SOFC porous electrodes was constructed using the scale factor t, which combines the existing EMT and ME1 mathematical models. In addition, the validity and high precision of the effective thermal conductivity model were verified by comparing the calculated values with the experimental measurements of the surface temperatures of the three test specimens with the porosity of 0.2349~0.4178.

-

Key words:

- SOFC /

- porous electrode /

- effective thermal conductivity /

- porous model

-

表 1 不同加热温度下实验测量值

Table 1. Experimental measurements at different heating temperatures

工况 电压/V 电流/A 加热器温度/K 气体温度/K 外壁/K 多孔电极测点温度/K TheatL TheatH Tgasin Tgasout Tsurf 测点7 测点17 测点23 测点37 测点45 测点52 1 40 0.46 363.5 372.1 293.5 295.8 294.3 335.4 339.4 343.8 350.8 353.8 354.7 2 80 0.92 578.4 612.4 295.7 312.6 297.3 479.1 504.4 516.4 551.0 560.3 574.8 3 120 1.34 810.8 861.2 298.9 345.7 297.3 670.3 738.8 759.0 814.4 828.6 834.3 4 160 1.78 877.7 932.4 300.9 360.4 305.3 706.7 808.1 845.0 887.8 890.8 906.1 注:TheatL为近气体入口端加热器温度, TheatH为近气体出口端加热器温度 表 2 不同加热温度下各比例因子对应的标准差

Table 2. Standard deviation corresponding to each scale factor at different heating temperatures

T/K 比例因子t 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 372.1 2.33031 2.32619 2.32447 2.32399 2.32667 2.33107 2.33726 2.34496 2.35466 612.4 6.75532 6.69697 6.65073 6.61661 6.59789 6.59404 6.59349 6.60450 6.63037 861.2 6.94167 6.32564 5.80576 5.40128 5.09935 4.94486 4.93141 5.05898 5.30833 932.4 8.30279 7.39442 6.54582 5.76892 5.12351 4.57371 4.20319 4.04781 4.10757 表 3 不同孔隙率下实验测量值

Table 3. Experimental measurements at different porosity

工况 孔隙率εp 加热器温度/K 气体温度/K 外壁/K 多孔电极测点温度/K TheatL TheatH Tgasin Tgasout Tsurf 测点7 测点17 测点23 测点37 测点45 测点52 1 0.2349 602.1 635.3 295.7 322.2 306.4 445.5 505.6 532.6 548.1 557.0 565.3 2 0.3471 578.4 612.4 295.7 312.6 297.3 479.1 504.4 516.4 551.0 560.3 574.8 3 0.4178 611.9 642.2 315.5 345.6 329.7 511.3 566.0 590.5 603.1 604.5 616.6 注:TheatL为近气体入口端加热器温度, TheatH为近气体出口端加热器温度 -

[1] Gupta N, Yadav G D. Solid oxide fuel cell: a review[J]. International Research Journal of Engineering and Technology, 2016, 3(6): 1006-1011. http://d.old.wanfangdata.com.cn/Periodical/xyjsclygc200508001 [2] Koteswararao P, Suresh M B, Wanic B N, et al. Review on ceramics for solid oxide fuel cells[J]. International Journal of Scientific Research in Science, Engineering and Technology, 2017, 3(8): 342-346. [3] Zeng S M, Xu M, Parbey J, et al. Thermal stress analysis of a planar anode-supported solid oxide fuel cell: Effects of anode porosity[J]. International Journal of Hydrogen Energy, 2017, 42(31): 20239-20248. doi: 10.1016/j.ijhydene.2017.05.189 [4] Barelli L, Bidini G, Ottaviano A. Solid oxide fuel cell modeling: Electrochemical performance and thermal management during load following operation[J]. Energy, 2016, 115: 107-119. doi: 10.1016/j.energy.2016.08.107 [5] Boaro M, Aricò A S. Advances in medium and high temperature solid oxide fuel cell technology[M]. Cham, Switzerland: Springer, 2017. [6] Rao Z H, Wang Q C, Huang C L. Investigation of the thermal performance of phase change material/mini-channel coupled battery thermal management system[J]. Applied Energy, 2016, 164: 659-669. doi: 10.1016/j.apenergy.2015.12.021 [7] 姚凯, 郑会保, 刘运传, 等.导热系数测试方法概述[J].理化检验(物理分册), 2018, 54(10): 741-747. http://d.old.wanfangdata.com.cn/Periodical/lhjy-wl201810007Yao K, Zheng H B, Liu Y C, et al. Survey of measurement methods for thermal conductivity[J]. Physical Testing and Chemical Analysis (Part A: Physical Testing), 2018, 54(10): 741-747. http://d.old.wanfangdata.com.cn/Periodical/lhjy-wl201810007 [8] 刘世杰, 吴鹏章, 王梦蛟, 等.一种基于稳态热流法的导热系数测定仪器及方法[J].橡塑技术与装备, 2017, 43(17): 45-47. http://d.old.wanfangdata.com.cn/Periodical/xsjsyzb201717010Liu S J, Wu P Z, Wang M J, et al. An instrument and method for measuring the thermal conductivity based on steady-state heat flow method[J]. China Rubber/Plastics Technology and Equipment, 2017, 43(17): 45-47. http://d.old.wanfangdata.com.cn/Periodical/xsjsyzb201717010 [9] 任佳, 蔡静.导热系数测量方法及应用综述[J].计测技术, 2018, 38(S1): 46-49. http://d.old.wanfangdata.com.cn/Periodical/hkjcjs2018z1014Ren J, Cai J. Summary of measurement methods and applications of thermal conductivity[J]. Metrology & Measure-ment Technology, 2018, 38(S1): 46-49. http://d.old.wanfangdata.com.cn/Periodical/hkjcjs2018z1014 [10] Radovic M, Lara-Curzio E, Trejo R M, et al. Thermophysical properties of YSZ and Ni-YSZ as a function of temperature and porosity[J]. Advances in Solid Oxide Fuel Cells Ⅱ: Ceramic Engineering and Science Proceedings, 2009, 27(4): 79-85. http://cn.bing.com/academic/profile?id=8bebe7971bd1bf149388c9bc1e7ce6f1&encoded=0&v=paper_preview&mkt=zh-cn [11] 付文强, 高辉, 薛征欣, 等.多孔材料有效导热系数的实验和模型研究[J].中国测试, 2016, 42(5): 124-130. http://d.old.wanfangdata.com.cn/Periodical/zgcsjs201605026Fu W Q, Gao H, Xue Z X, et al. Experimental measurement and calculation of thermal conductivity of porous material[J]. China Measurement & Test, 2016, 42(5): 124-130. http://d.old.wanfangdata.com.cn/Periodical/zgcsjs201605026 [12] 王刚, 魏高升, 黄平瑞, 等.改进的新有效介质理论模型分析多孔绝热材料的有效导热系数[J].中国电机工程学报, 2016, 36(9): 2465-2469. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgdjgcxb201609019Wang G, Wei G S, Huang P R, et al. Effective thermal conductivity analysis on porous thermal insulation material by the improved novel effective medium theory model[J]. Proceedings of the CSEE, 2016, 36(9): 2465-2469. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgdjgcxb201609019 [13] 付俊鹏, 蔡九菊.基于谢尔宾斯基地毯模型对烧结矿散料有效导热系数的研究[J].冶金能源, 2017, 36: 59-61. http://www.cqvip.com/QK/95660X/2017A01/673049683.htmlFu J P, Cai J J. Research of the effective thermal conductivity of sinter packed based on sierpinski carpet[J]. Energy for Metallurgical Industry, 2017, 36: 59-61. http://www.cqvip.com/QK/95660X/2017A01/673049683.html [14] 王世芳, 吴涛.多孔介质有效热导率的一种新模型[J].工程热物理学报, 2016, 37(12): 2626-2630. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gcrwlxb201612022Wang S F, Wu T. A new fractal model for the effective thermal conductivity of porous media[J]. Journal of Engineering Thermophysics, 2016, 37(12): 2626-2630. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gcrwlxb201612022 [15] Zhai S P, Zhang P, Shi B, et al. Effective thermal conductivity of polymer composites: Theoretical models and simulation models[J]. International Journal of Heat and Mass Transfer, 2018, 117: 358-374. doi: 10.1016/j.ijheatmasstransfer.2017.09.067 [16] Carson J K, Lovatt S J, Tanner D J, et al. Predicting the effective thermal conductivity of unfrozen, porous foods[J]. Journal of Food Engineering, 2006, 75(3): 297-307. doi: 10.1016/j.jfoodeng.2005.04.021 -

下载:

下载: