Orthogonal analysis of the influencing factors of gas-solid two-phase jet particles

-

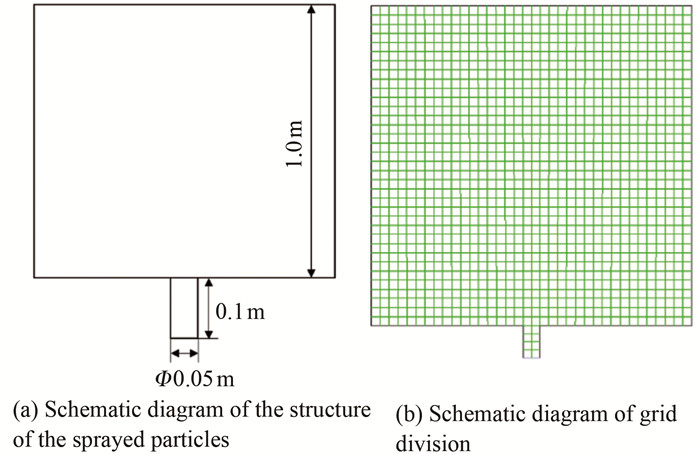

摘要: 气固两相颗粒喷射技术应用广泛,故对其影响因素的研究具有重要的工程意义。首先利用正交实验设计原理对压强与质量2个因素进行安排实验;然后基于CFD-DEM模型利用FLUENT进行数值模拟,将计算的结果进行极差分析和方差分析;最后设计一套喷射实验,拍摄颗粒喷射轨迹,并将拍摄图片进行颜色直方图处理。得出以下结论:通过极差分析和方差分析得出压强的影响大于质量,且当压强为0.3 MPa、质量为2 g时,其均值最小;当压强取值为0.3 MPa、质量取值为2 g时,其喷射效果达到最优化,且拍摄的效果最佳,与数值模拟的结果一致。Abstract: Since the gas-solid two-phase particle injection technology is widely used, it is of great engineering significance to study its influencing factors. Firstly, to inverstigate two factors, pre-ssure and mass, experiments are arranged by the orthogonal experimental design principle. Then, based on the CFD-DEM model, the FLUENT software is used for numerical simulation, and the results are analyzed by range analysis and variance analysis. Finally, a set of jet experiments is designed to obtain the particle injection trajectory, and the photographs are processed by color histogram. The following conclusions are drawn: the influence of pressure is greater than that of mass by range analysis and variance analysis, and the mean value is the smallest when the pressure is 0.3 MPa and the mass is 2 g. When the pressure is 0.3 MPa and the mass is 2 g, the injection effect is optimized, and the shooting effect is the best, which is consistent with the results of numerical simulation.

-

Key words:

- gas-solid two-phase /

- orthogonal analysis /

- CFD-DEM /

- numerical simulation /

- color histogram

-

表 1 Specified parameters

Table 1. Specified parameters

Factors Exp. 1 Exp. 2 Exp. 3 Exp. 4 Exp. 5 Exp. 6 Exp. 7 Exp. 8 Exp. 9 Exp.10 Exp.11 Exp.12 Exp.13 Exp.14 Exp.15 Exp.16 Pressure/MPa 0.2 0.2 0.2 0.2 0.3 0.3 0.3 0.3 0.4 0.4 0.4 0.4 0.5 0.5 0.5 0.5 Quality/g 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 表 2 Tracking the number of particles trapping and the total number of particles (500 steps)

Table 2. Tracking the number of particles trapping and the total number of particles (500 steps)

Factors Exp.1 Exp.2 Exp.3 Exp.4 Exp.5 Exp.6 Exp.7 Exp.8 Exp.9 Exp.10 Exp.11 Exp.12 Exp.13 Exp.14 Exp.15 Exp.16 Trap number 40 74 81 66 42 21 39 31 44 30 35 41 66 45 42 87 Total number 321 327 259 251 186 215 146 349 146 151 93 114 143 190 140 179 表 3 Variance analysis of pressure and quality impact

Table 3. Variance analysis of pressure and quality impact

Factors Square of

devianceDegree of

freedomF

ratioF

critical-valuePressure 0.093 3 1.431 4.760 Quality 0.037 3 0.569 4.760 Error 0.130 6 — — 表 4 Experimental measurement instrument list

Table 4. Experimental measurement instrument list

Serial number Device name Model number Manufacturing company 1 Air compressor OD1012 FujianJuba Machinery Co. LTD 2 Ball valve FG-55658 FEGEER 3 DMF-Z DMF-Z-20 CHCR 4 Powder particle —— HenanSuhe Biotechnology Co. LTD 5 Electronic scales JM1003 Yuyao Jiming Weighing and Verifying Equipment Co. LTD 6 High-speed camera Fastcam Ultima APX Photron Corporation of Japan -

[1] DINTWA E, TIJSKENS E, OLIESLAGERS R, et al. Calibration of a spinning disc spreader simulation model for accurate site-specific fertiliser application[J]. Biosystems Engineering, 2004, 88(1): 49-62. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=58aa3492d73cdc3b749f5f2a8fb821be [2] VILLETTE S, COINTAULT F, PIRON E, et al. Centrifugal spreading: an analytical model for the motion offertiliser particles on a spinning disc[J]. Biosystems Engineering, 2005, 92(2): 157-164. http://europepmc.org/abstract/AGR/IND43755294 [3] 雷小龙, 李蒙良, 张黎骅, 等.颗粒化肥水平气送式螺旋组合可调定量供肥装置设计与试验[J].农业工程学报, 2018, 34(19): 9-18. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=nygcxb201819002LEI X L, LI M L, ZHANG L H, et al. Design and experiment of horizontal pneumatic screw combination adjustable quantitative fertilizer feeding device for granular fertilizer[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(19): 9-18. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=nygcxb201819002 [4] NAJJAR F M, FERRY J P, HASELBACHER A, et al. Simulations of solid-propellant rockets: effects of aluminum droplet size distribution[J]. Journal of Spacecraft and Rockets, 2006, 43(6): 1258-1270. doi: 10.2514/1.17326 [5] 刘辉, 邢玉明.燃气喷射推力矢量喷管气固两相流数值模拟[J].航空动力学报, 2013, 28(1): 151-157. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hkdlxb201301021LIU H, XING Y M. Numerical simulation of gas-particle flow in hot gas injection thrust vector nozzle[J]. Journal of Aerospace Power, 2013, 28(1): 151-157. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hkdlxb201301021 [6] 谢剑波, 周建安, 李志强, 等.冶金炉外底喷粉气-固喷射器效率影响因素[J].中国冶金, 2016, 26(9): 59-62. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgyj201609012XIE J B, ZHOU J N, LI Z Q, et al. Influence factors of efficiency of gas-solid ejector with bottom powder injection outside furnace[J]. China Metallurgy, 2016, 26(9): 59-62. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgyj201609012 [7] 黄荣国, 陈星晶, 张红泉.直流燃烧器一次风通道气固两相流实验研究[J].水动力学研究与进展A辑, 2009, 24(1): 7-14. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=sdlxyjyjz200901002HUANG R G, CHEN X J, ZHANG H Q. Experimental studyof gas-particle two-phase flow in the primary air channel of direct-flow pulverized coal burner[J]. Journal of Hydrodynamics, 2009, 24(1): 7-14. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=sdlxyjyjz200901002 [8] LI W Y, HUANG C J, YU M, et al. Investigation of high temperature oxidation behavior andtribological performance on cold sprayed nickel-alumina composite coating[J]. Surface and Coatings Technology, 2014, 239: 95-101. http://www.sciencedirect.com/science/article/abs/pii/S0257897213011006 [9] 华敏, 徐大用, 潘旭海, 等.超细微粒灭火剂运动特性的数值模拟[J].安全与环境学报, 2013, 13(06): 181-185. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=aqyhjxb201306040HUA M, XU D Y, PAN X H, et al. Simulated research on the dynamic features of the superfine fire-extinguishing powder[J]. Journal of Safety and Environment, 2013, 13(6): 181-185. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=aqyhjxb201306040 [10] LI M, CHRISTOFIDES P D. Multi-scale modeling and analysis of an industrial HVOF thermal spray process[J]. Chemical Engineering Science, 2005, 60(13): 3649-3669. doi: 10.1016/j.ces.2005.02.043 [11] 张海峰, 余柄辰, 田世伟.气固喷射器收缩型喷嘴的仿真模拟及实验[J].煤炭技术, 2018, 37(1): 245-247. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=mtjs201801092ZHANG H F, YU B C, TIAN S W. Simulation and experiment of converging nozzle in gas-solid injector[J]. Coal Technology, 2018, 37(1): 245-247. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=mtjs201801092 [12] 王军, 赵英涛, 曹丽, 等.钛渣喷动床沸腾氯化气固两相流数值模拟[J].矿产保护与利用, 2017(6): 66-74. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=kcbhyly201706014WANG J, ZHAO Y T, CAO L, et al. Numerical simulation of titanium slag flow fluid-bed chlorination in spout fluidized bed[J]. Conservation and Utilization of Mineral Resources, 2017(6): 66-74. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=kcbhyly201706014 [13] WANG Z Q, HU Y J, CHENG X X, et al. Influence of offset angle of mid-secondary air nozzles on gas-particle flow characte-ristics in a furnace[J]. RSC Advances, 2018, 8(32): 17764-17772. doi: 10.1039/C8RA02405G [14] WANG Y M, LYU X Q, LI W T, et al. Investigation on measurement of size and concentration of solid phase particles in gas-solid two phase flow[J]. Chinese Journal of Electronics, 2018, 27(2): 381-385. doi: 10.1049/cje.2017.12.005 [15] SOKOLOV E Y, ZINGER N M. Ejector[M]. Moscow: Energy Press, 1970. [16] CHELLAPPAN S, RAMAIYAN G. Experimental study of design parameters of a gas-solid injector feeder[J]. Powder Technology, 1986, 48(2): 141-144. doi: 10.1016/0032-5910(86)80072-9 [17] 郑金宝, 史慧玲, 梁译远.气固喷射器的理论和实验研究[J].水泥, 1993(7): 14-18. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000002822488ZHENG J B, SHI H L, LIANG Y Y. Theoretical and experimental study of gas-solid ejector[J]. Cement, 1993(7): 14-18. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000002822488 [18] CAI D J, SHU Q, XU B Q, et al. Orthogonaltest design for optimization of the extraction of flavonid from the fructus gardeniae[J]. Biomedical and Environmental Sciences, 2011, 24(6): 688-693. http://www.cqvip.com/QK/84046X/201106/40729777.html [19] 宋鑫华, 闫鸿浩.基于尖点突变理论的浆砌块石边坡稳定性研究[J].岩土力学, 2016, 37(12): 3499-3505. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ytlx201612019SONG X H, YAN H H. Analysis of stability of masonry slope based on cusp catastrophe theory[J]. Rock and Soil Mechanics, 2016, 37(12): 3499-3505. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ytlx201612019 [20] 宋鑫华, 闫鸿浩, 马征征, 等.基于传输线理论的电磁波反射系数正交分析[J].科学技术与工程, 2018, 18(12): 137-141. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=kxjsygc201812021SONG X H, YAN H H, MA Z Z, et al. Orthogonal analysis of electromagnetic wave reflection coefficient based on transmission line theory[J]. Science Technology and Engineering, 2018, 18(12): 137-141. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=kxjsygc201812021 [21] ZHONG W Q, YU A B, LIU X J, et al. DEM/CFD-DEM modelling of non-spherical particulate systems: theoretical developments and applications[J]. Powder Technology, 2016, 302: 108-152. doi: 10.1016/j.powtec.2016.07.010 [22] YE M, VAN DER HOEF M A, KUIPERS J A M. A numerical study of fluidization behavior of Geldart A particles using a discrete particle model[J]. Powder Technology, 2004, 139(2): 129-139. doi: 10.1016/j.powtec.2003.10.012 [23] 贾月梅, 赵秋霞, 赵广惠.流体力学[M].北京:国防工业出版社, 2006.JIA Y M, ZHAO Q X, ZHAO G H. Fluid dynamics[M]. Beijing: National Defense Industry Press, 2009. [24] 北京工业学院.爆炸及其作用(上册)[M].北京:国防工业出版社, 1979. [25] 童秉纲, 孔祥言, 邓国华.气体动力学[M]. 2版.北京:高等教育出版社, 2012.TONG B G, KONG X Y, DENG G H. Gas dynamics. 2nd edition[M]. Beijing: Higher Education Press, 2012. [26] 吕晓兰, 张美娜, 常有宏, 等.果园风送喷雾机导流板角度对气流场三维分布的影响[J].农业工程学报, 2017, 33(15): 81-87. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=nygcxb201715010LYU X L, ZHANG M N, CHANG Y H, et al. Influence of deflector angles for orchard air-assisted sprayer on 3D airflow distribution[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(15): 81-87. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=nygcxb201715010 [27] 高宗升, 滕岩梅.复变函数与积分变换[M].北京:北京航空航天大学出版社, 2006.GAO Z S, TENG Y M. Complex variable function and integral transform[M]. Beijing: Beijing University of Aeronautics & Astronautics Press, 2006. [28] 阮竞兰, 张双, 张海红.基于FLUENT对袋式除尘器气流流场的数值模拟[J].河南工业大学学报(自然科学版), 2015, 36(4): 16-19, 39.RUAN J L, ZHANG S, ZHANG H H. Numerical simulation of air distribution of bag-filter based on FLUENT[J]. Journal of Henan University of Technology (Natural Science Edition), 2015, 36(4): 16-19, 39. [29] 段中喆. ANSYS FLUENT流体分析与工程实例[M].北京:电子工业出版社, 2015.DUAN Z Z. ANSYS FLUENT fluid analysis and engineering example[M]. Beijing: Electronic Industry Press, 2015. [30] 冈萨雷斯, 伍兹.数字图像处理(第三版)[M].北京:电子工业出版社, 2010.GONZALEZ R C, WOODS R E. Digital image processing. 3rd edition[M]. Beijing: Publishing House of Electronics Industry, 2010. [31] PETROU M, SEVILLA P G. Image processing: dealing with texture[M]. Rhineland-palatinate: DBLP, 2006. -

下载:

下载: