Experimental study of passive control of jet deflection on wing upper surface

-

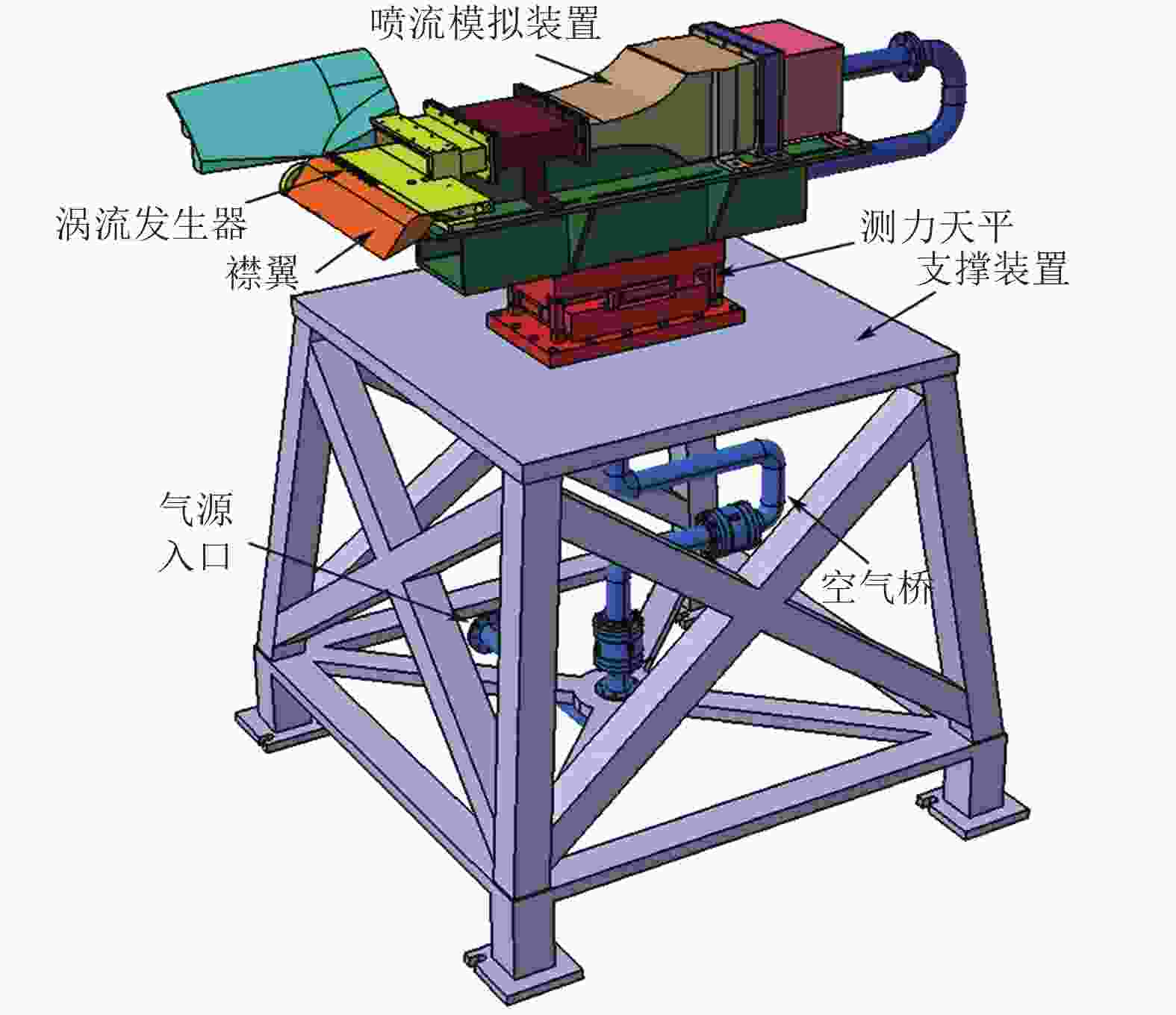

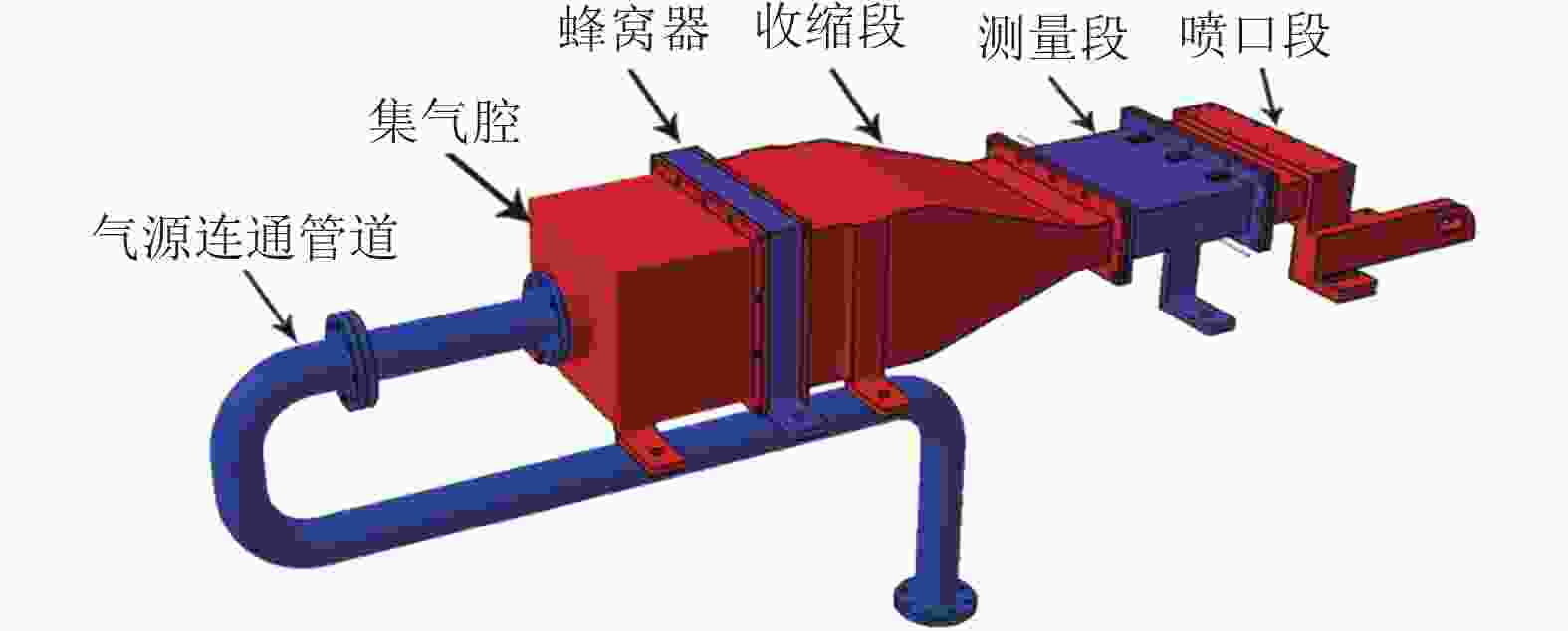

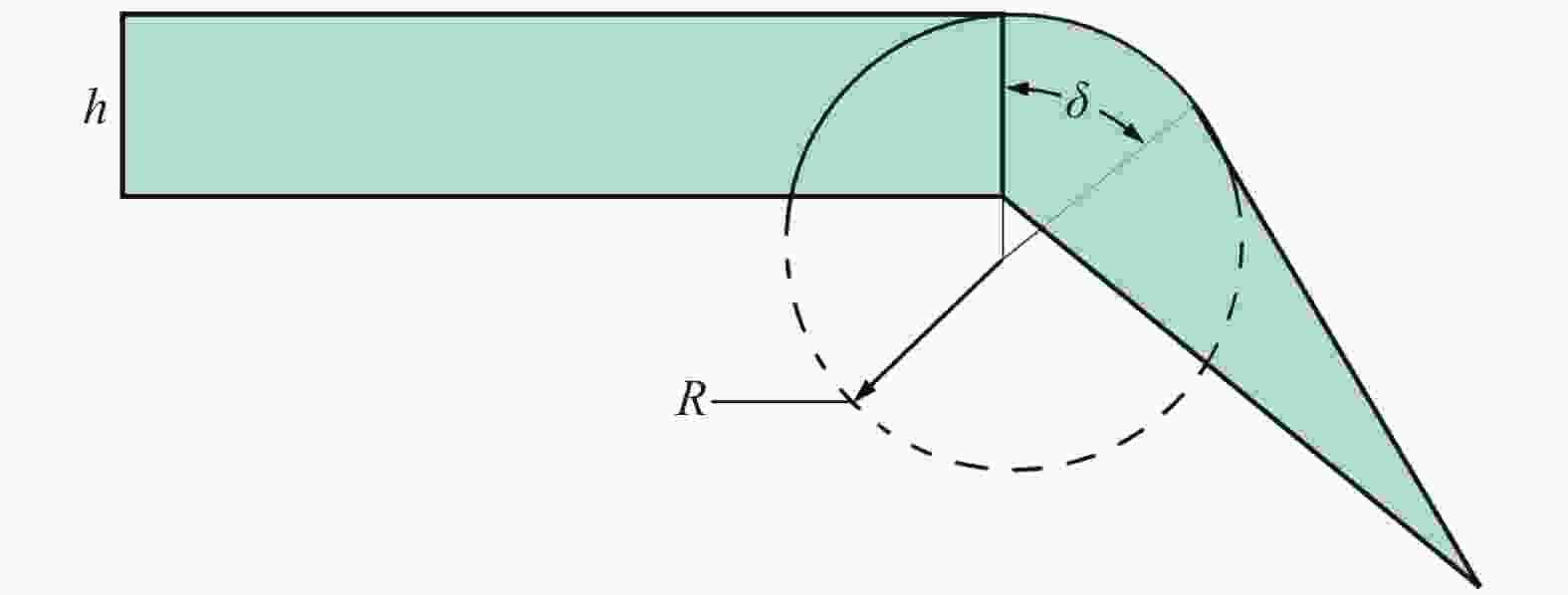

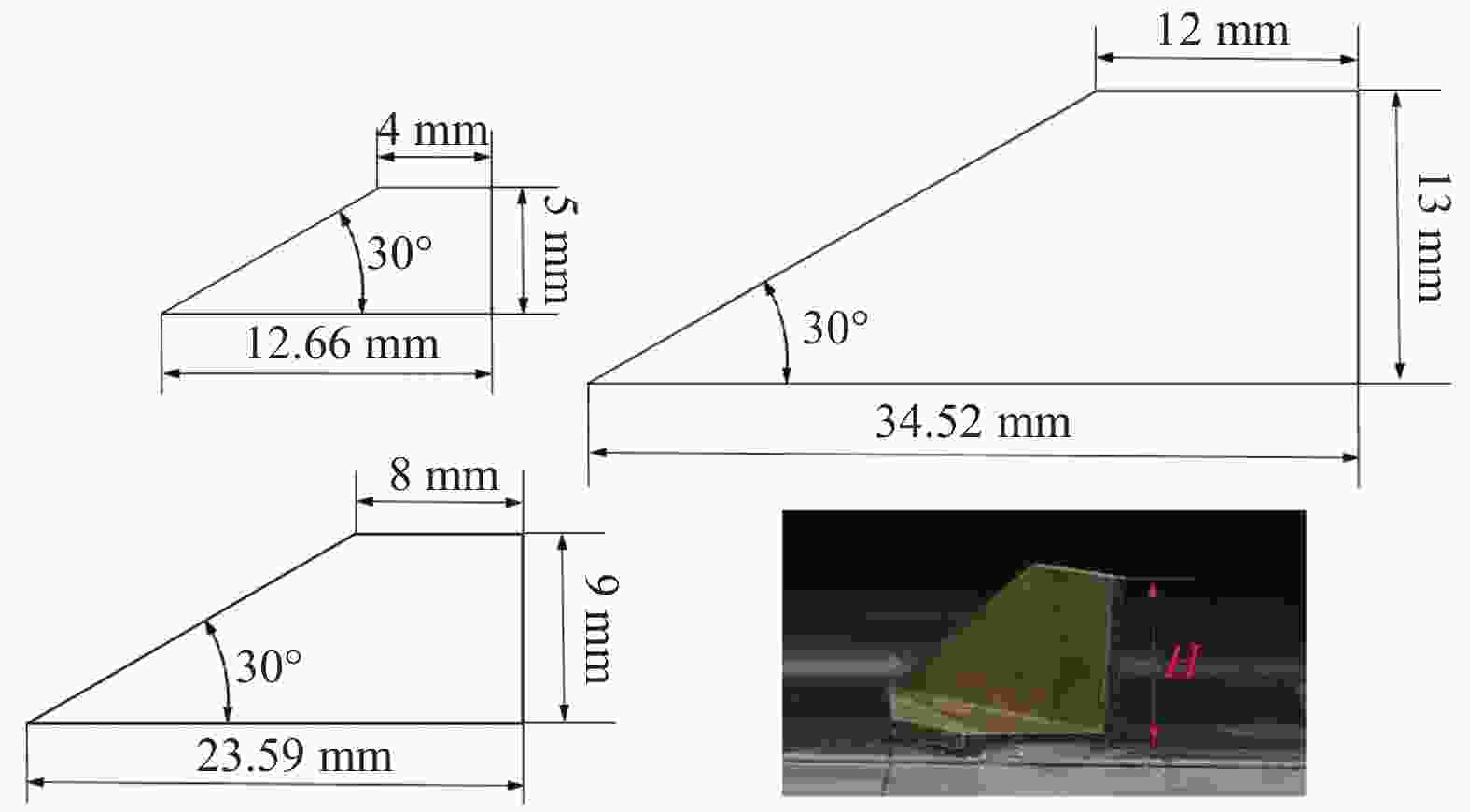

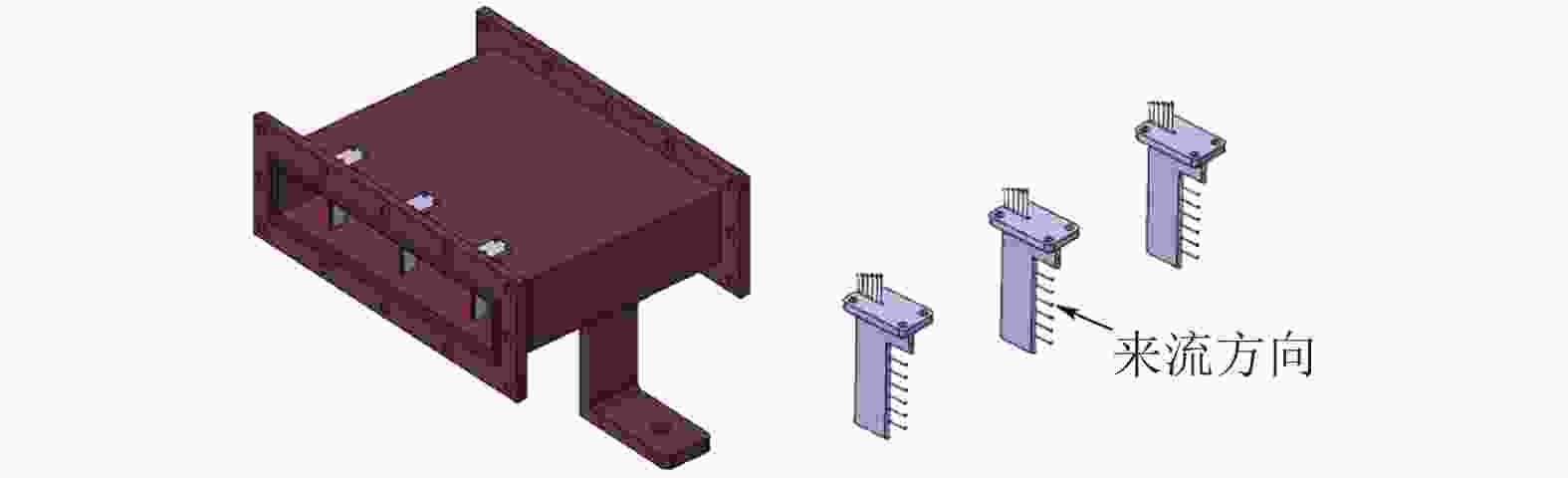

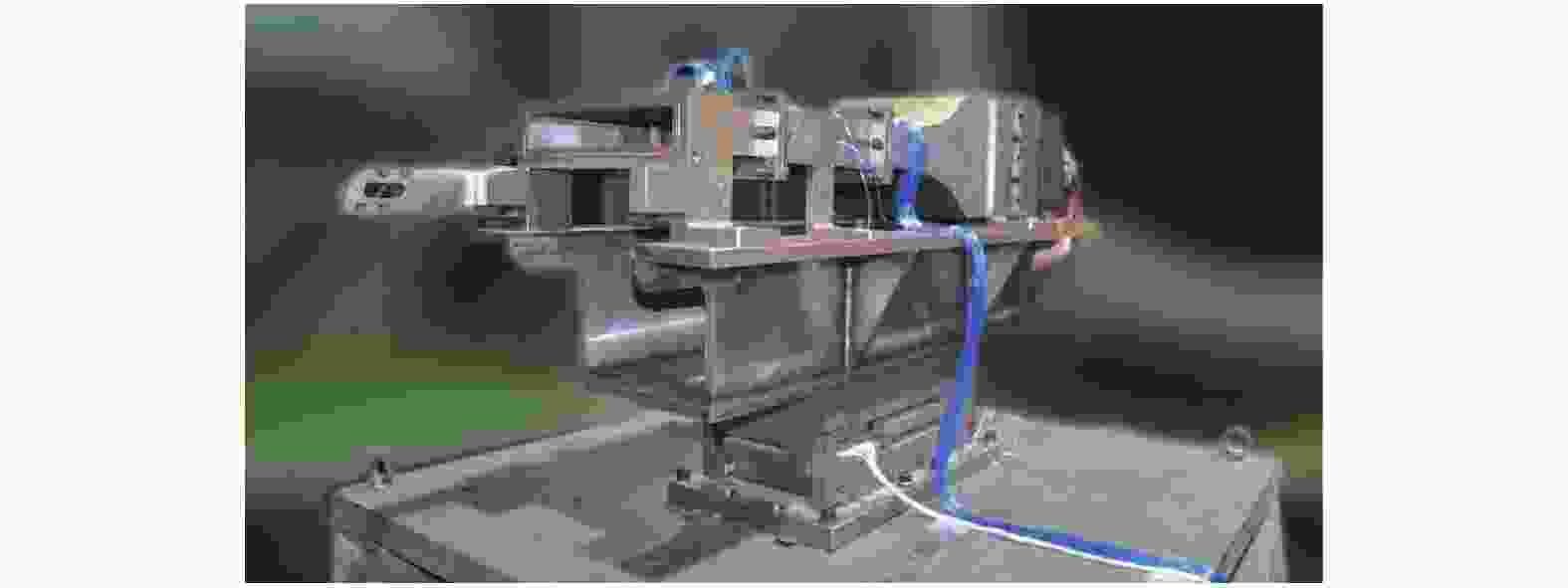

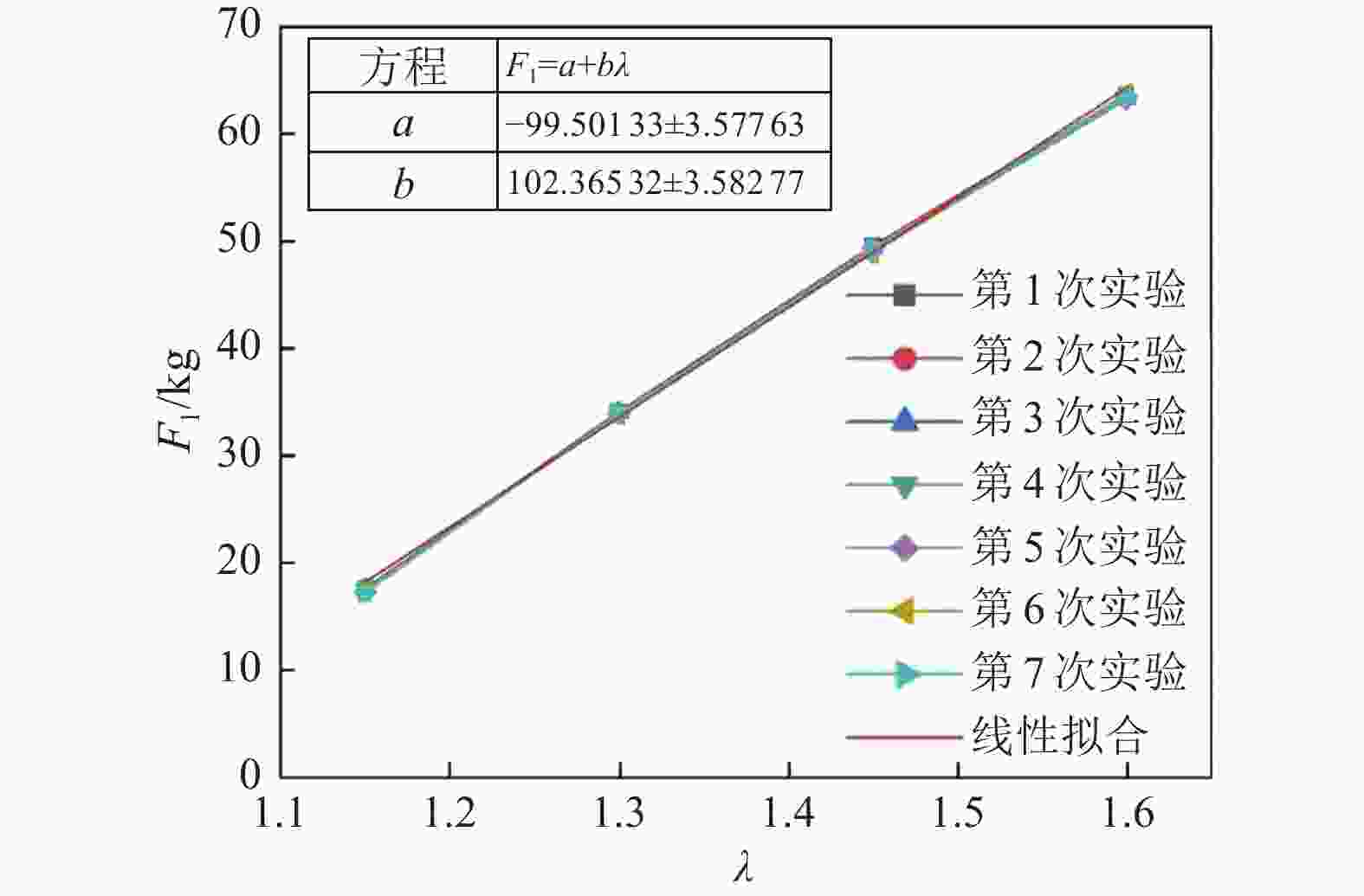

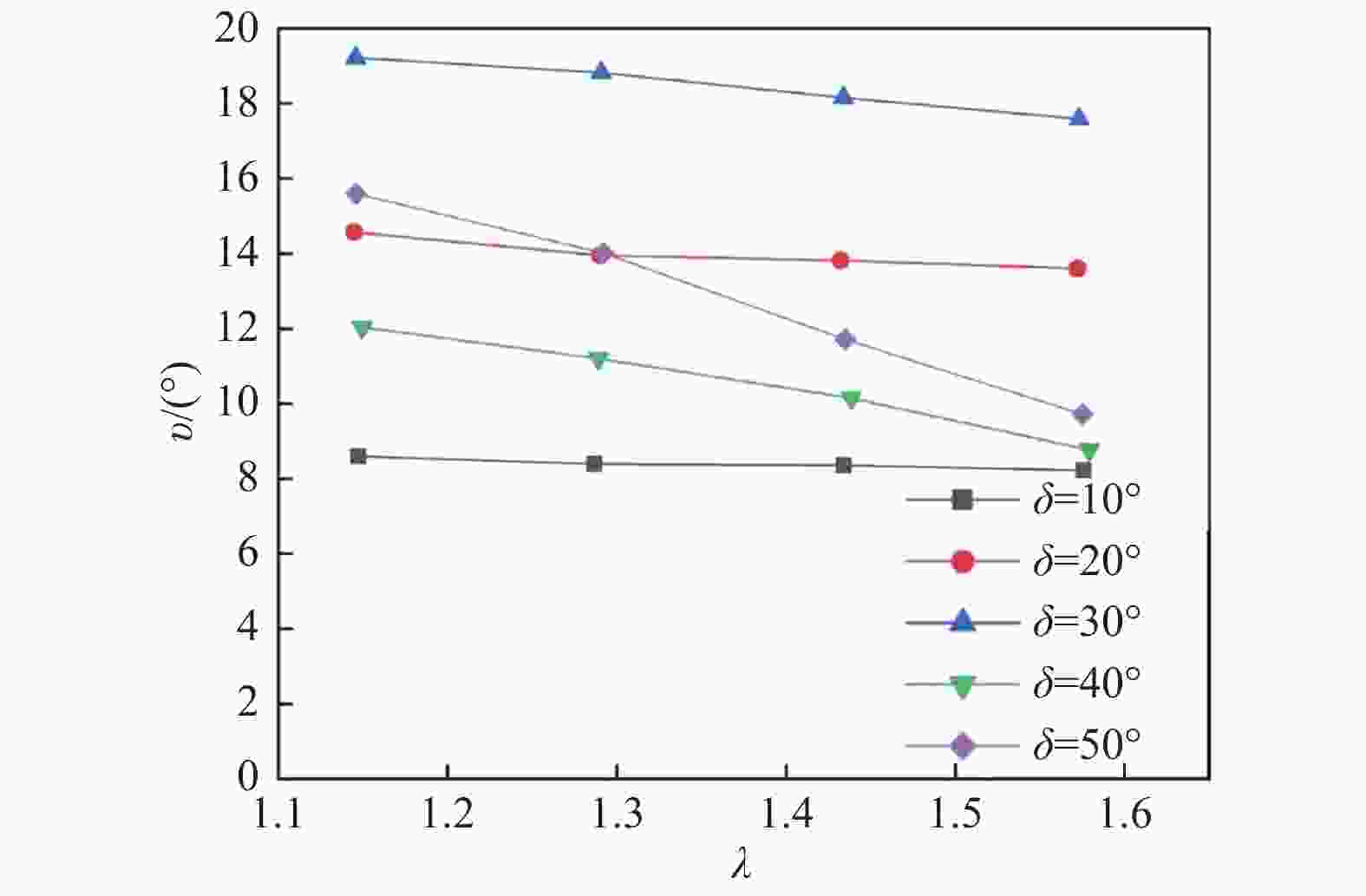

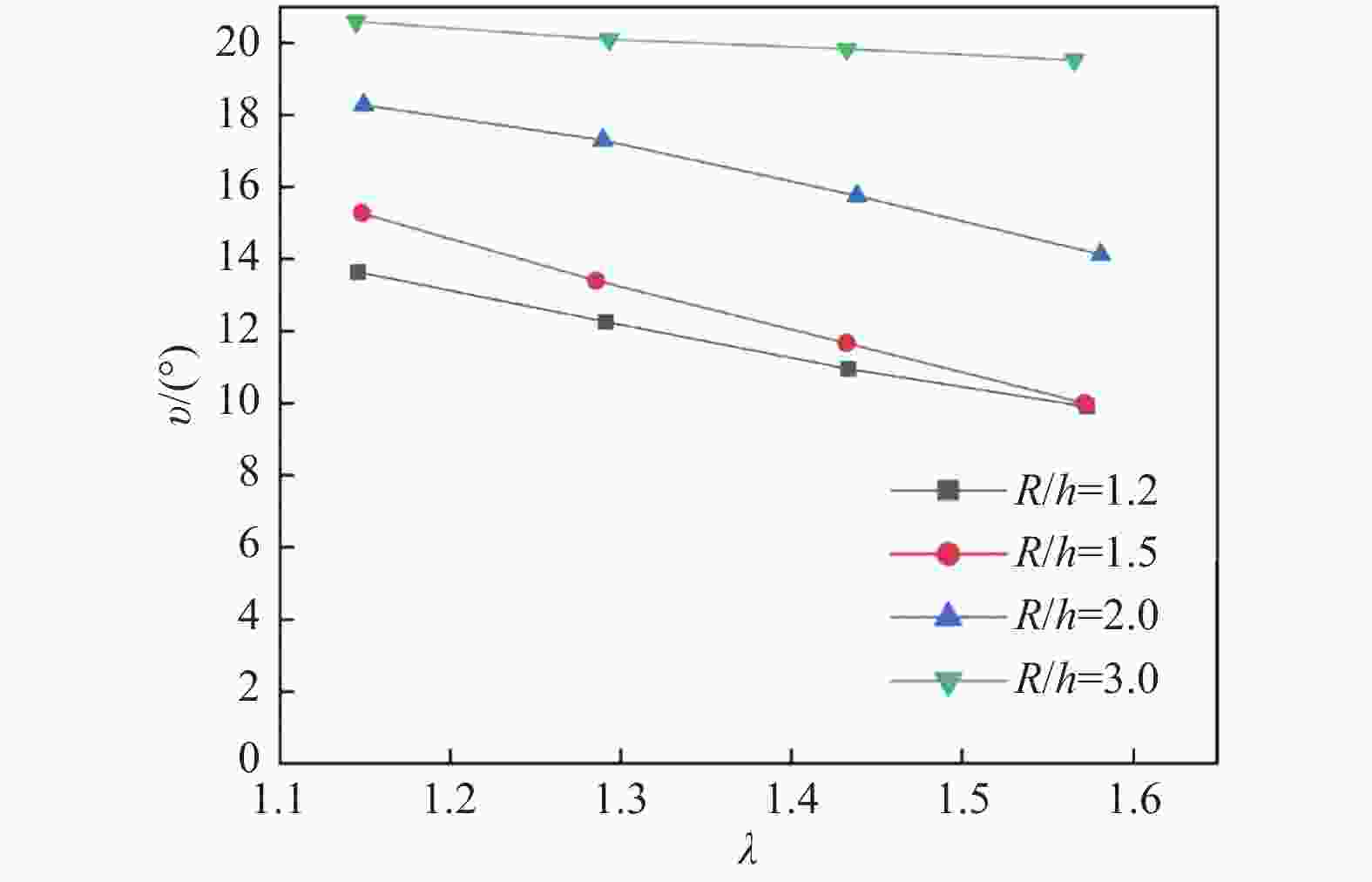

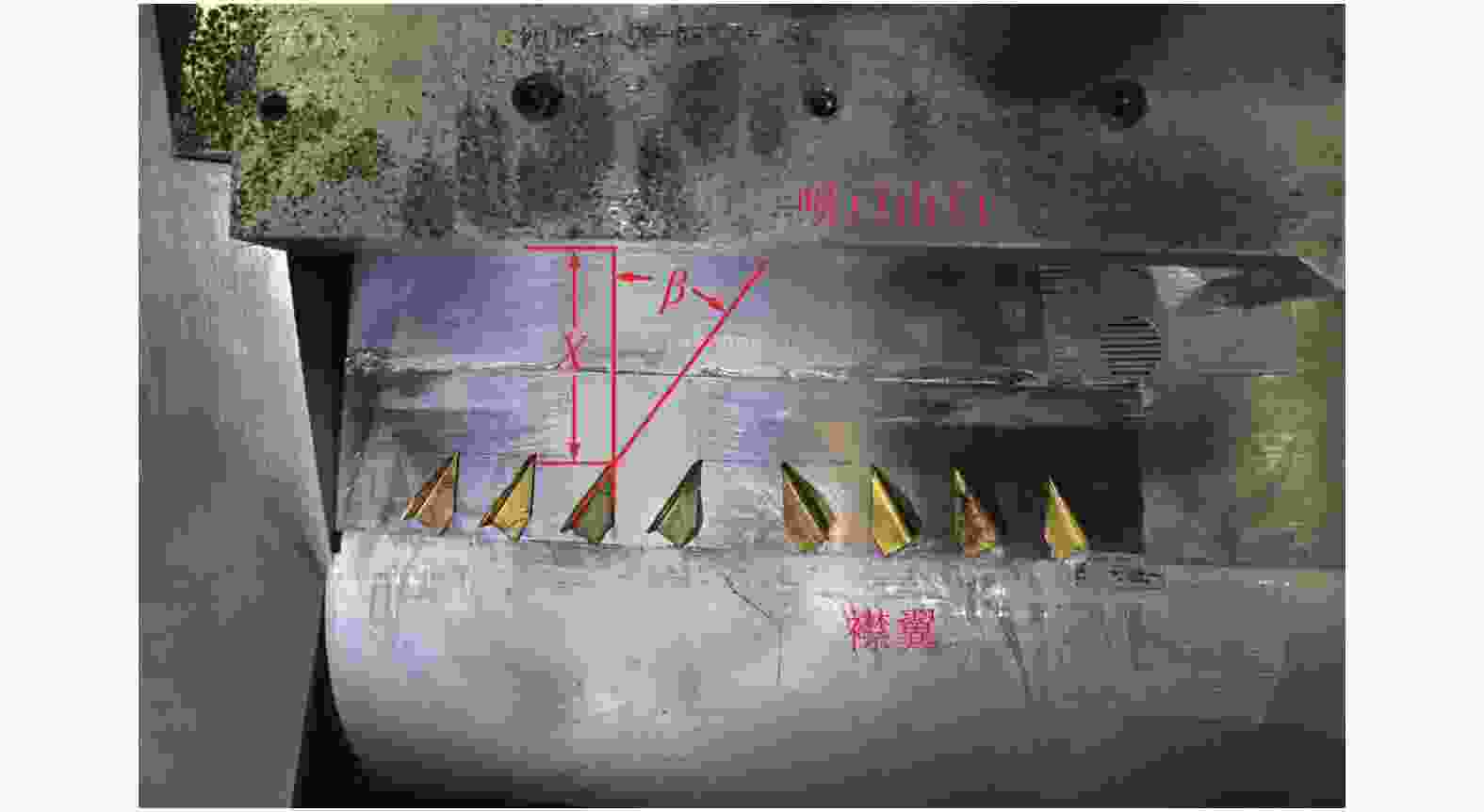

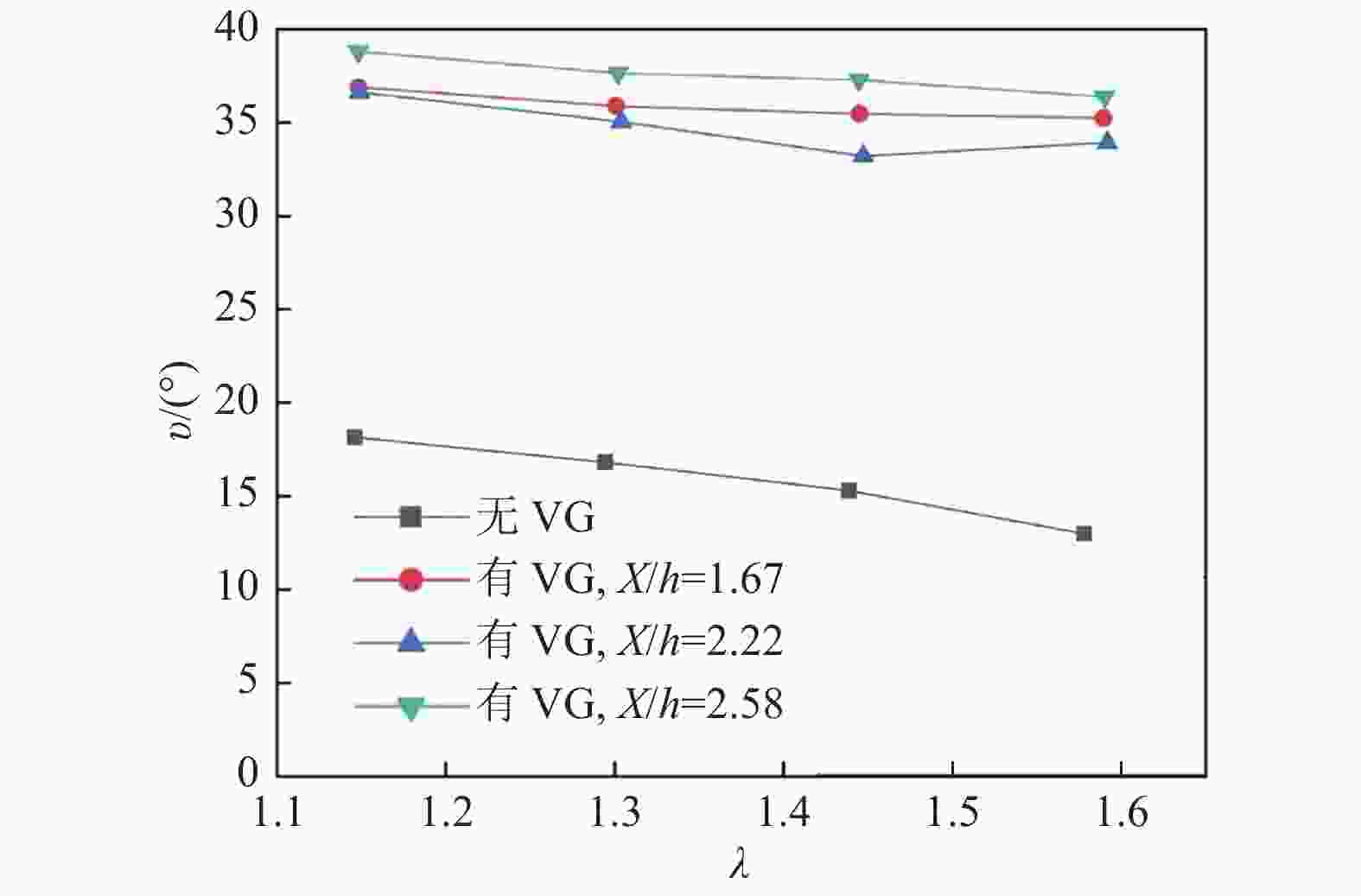

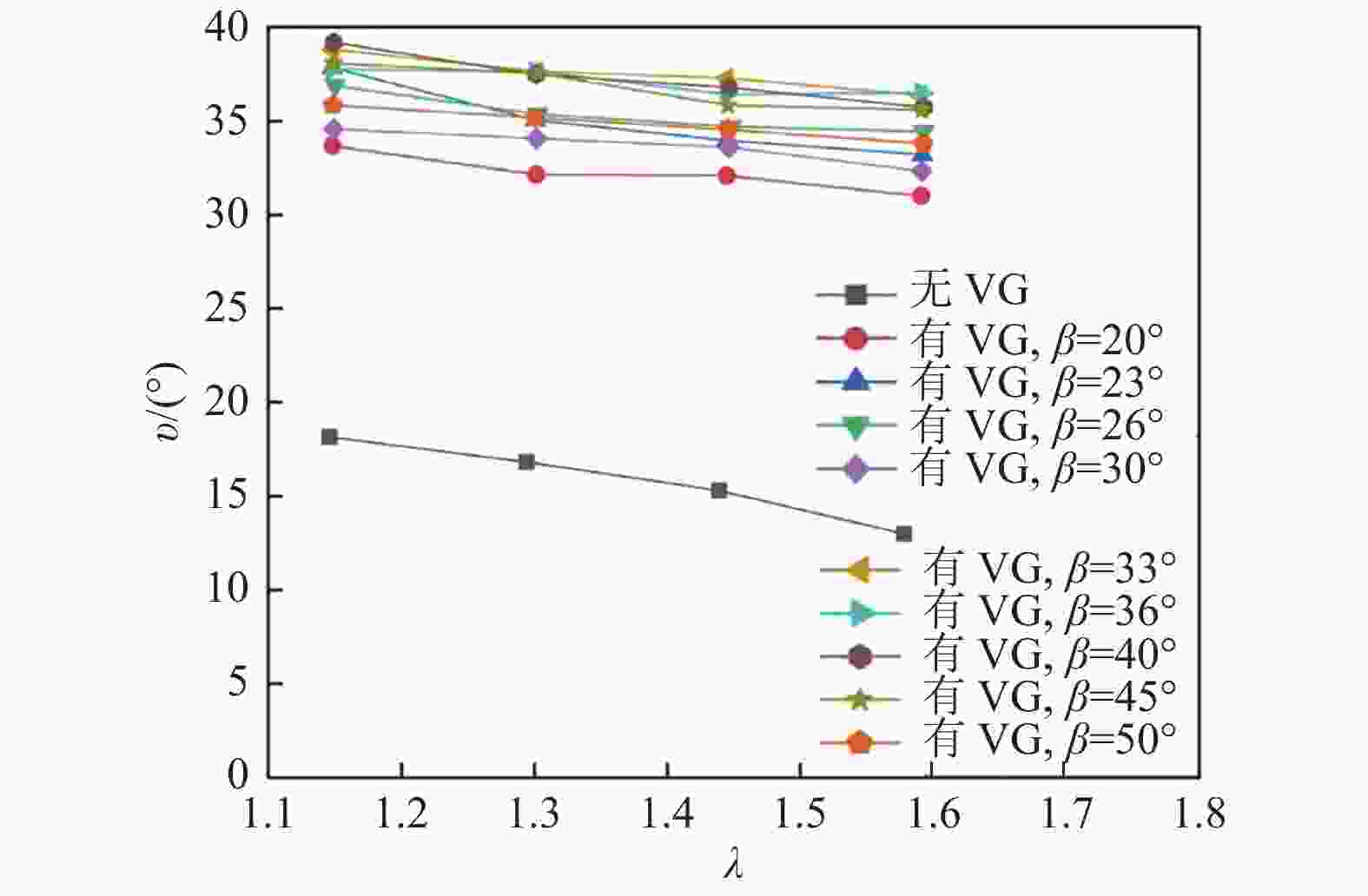

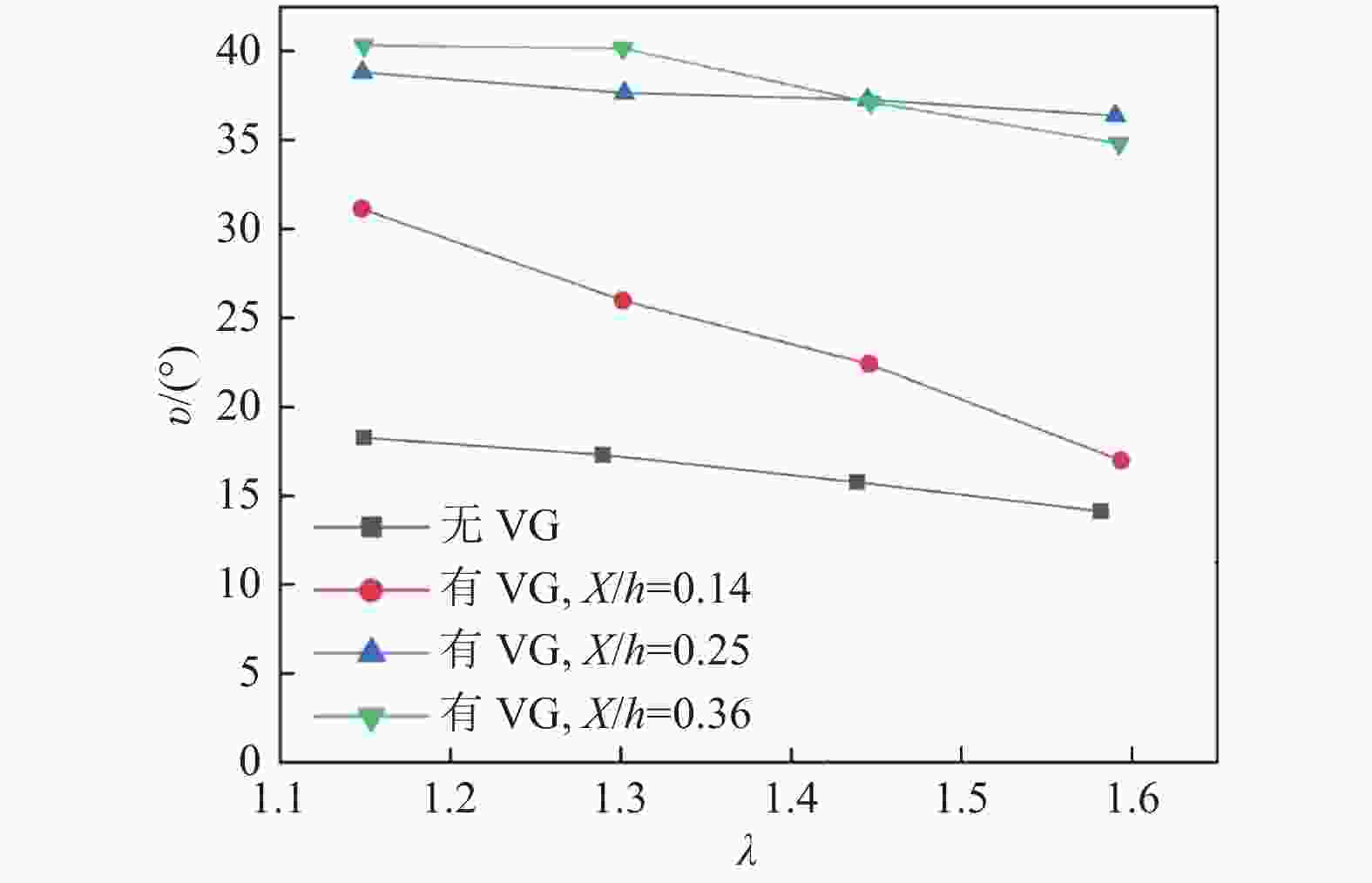

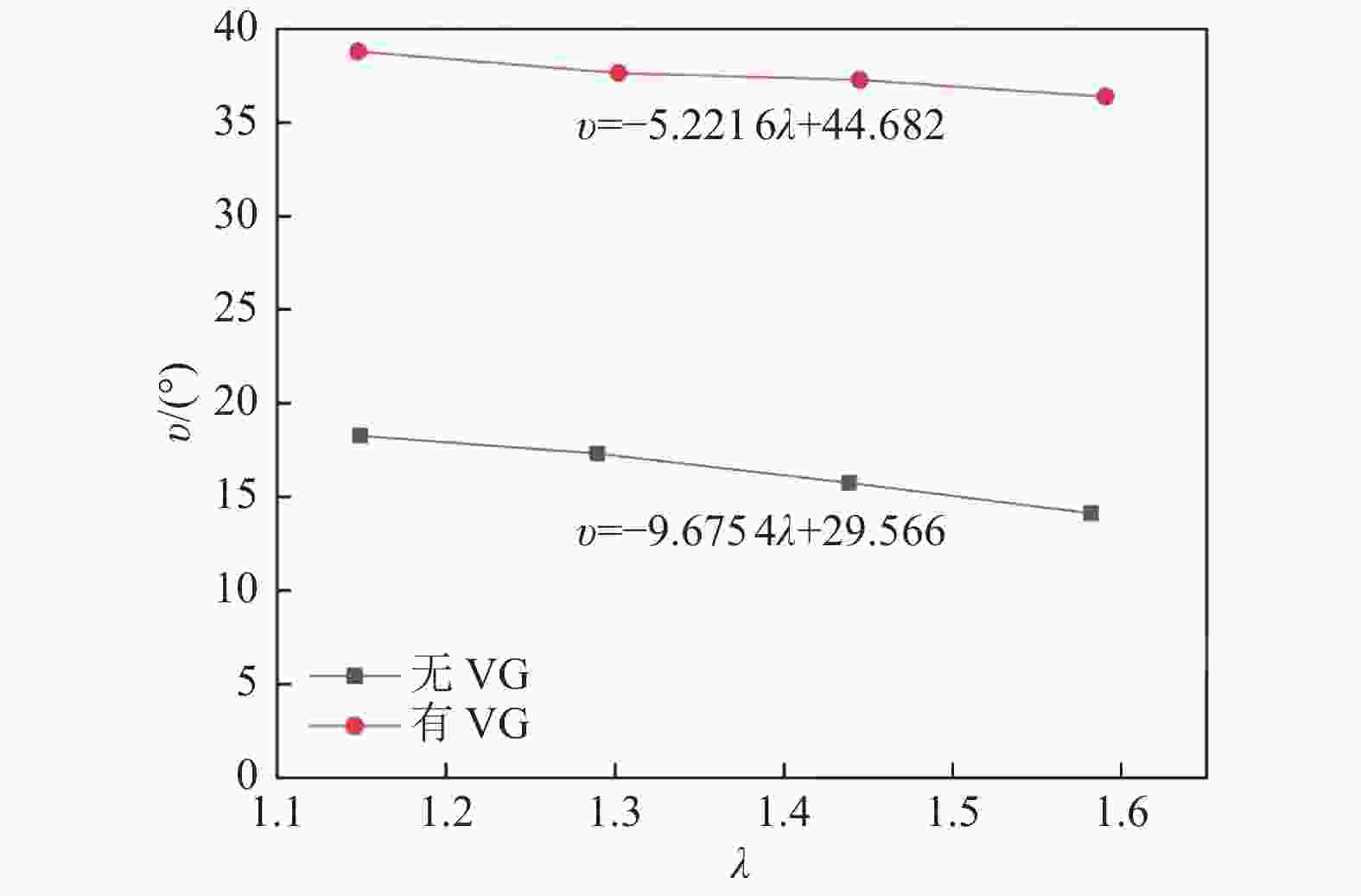

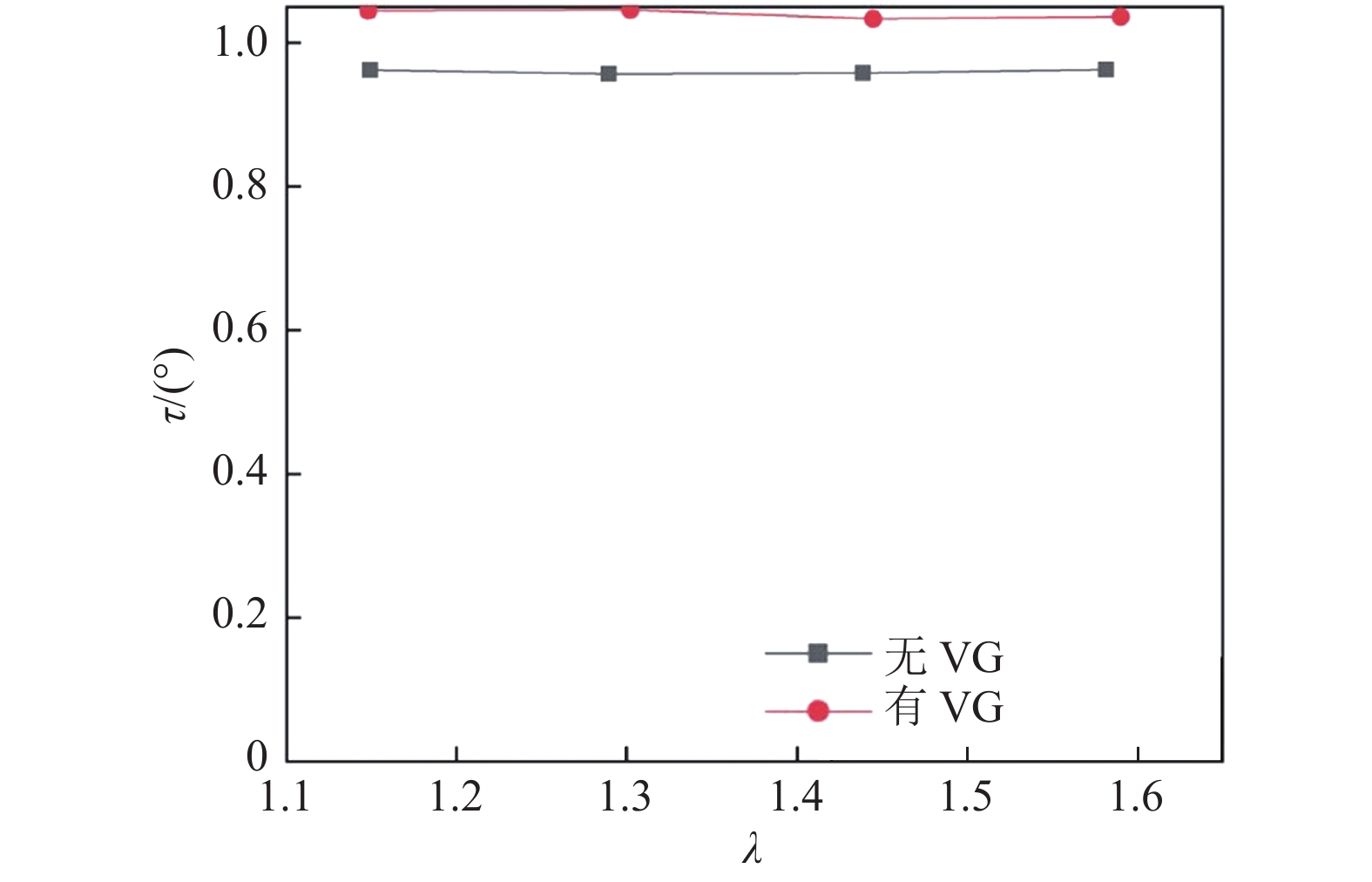

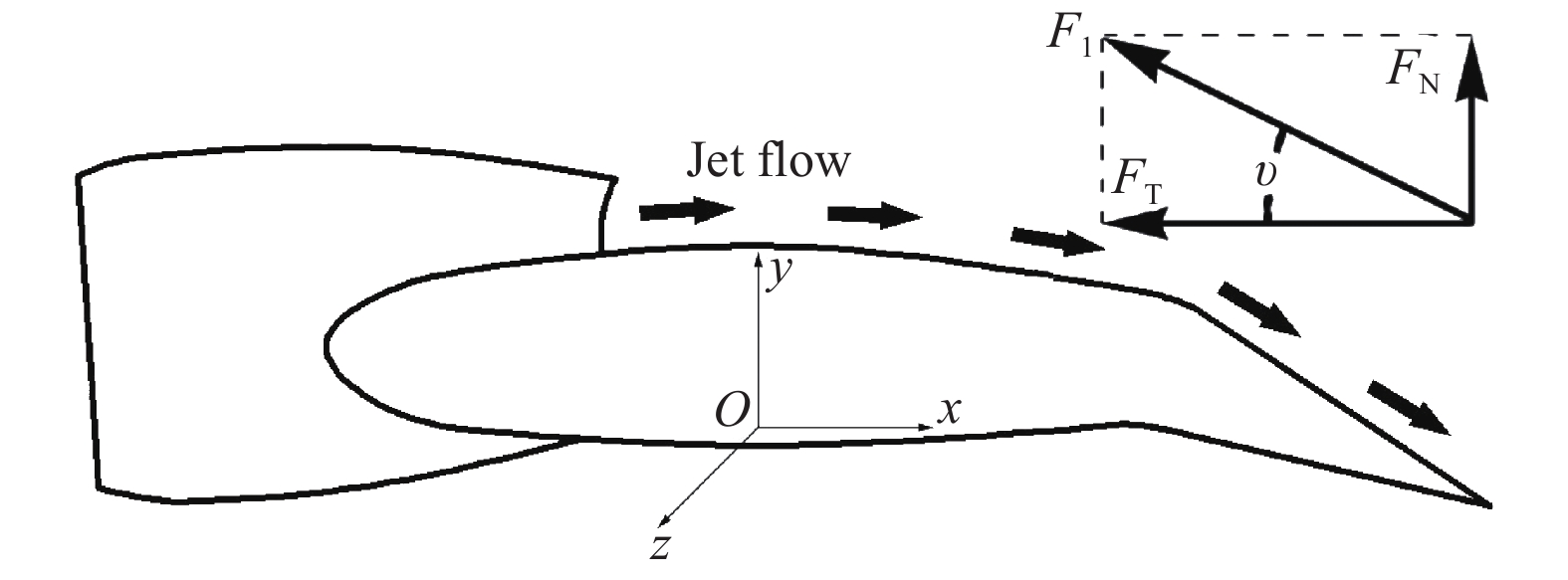

摘要: 通过静态推力实验,研究了襟翼形状对机翼上表面喷流偏转的影响。在此基础上,通过涡流发生器对喷流偏转进行被动控制,研究了涡流发生器安装位置、安装角和涡流发生器高度对喷流偏转性能的影响。结果表明:喷流偏角在襟翼偏角为30°时达到最大值,并随襟翼半径增大而增大;使用涡流发生器有助于促进喷流附着、增大喷流偏角;安装角和涡流发生器高度是影响喷流偏转性能的关键参数。Abstract: The effect of flap shape on jet deflection on the upper surface of the wing is studied by the static thrust experiment. On this basis, the jet deflection is passively controlled by the vortex generator, and the effects of the installation position, installation angle and height of the vortex generator on the jet deflection performance are studied. The results show that the jet deflection angle reaches the maximum when the flap deflection angle is 30° and increases with the increase of the flap radius. The use of vortex generators helps to promote the jet adhesion and to increase the jet deflection angle. Its height and installation angle are the key parameters that affect the deflection performance of the jet.

-

Key words:

- jet /

- upper surface blowing /

- vortex generator /

- control experiment

-

表 1 TH2003天平载荷及精度表

Table 1. Load and precision of TH2003 balance

分量 Fx Fy Fz Mx My Mz 设计载荷 1000 N 1500 N 1000 N 300 N·m 500 N·m 600 N·m 精度 0.02% 0.01% 0.01% 0.02% 0.02% 0.01% -

[1] 战培国,程娅红,赵昕. 主动流动控制技术研究[J]. 航空科学技术,2010,21(5):2-6. doi: 10.3969/j.issn.1007-5453.2010.05.001ZHAN P G,CHENG Y H,ZHAO X. A review of active flow control technology[J]. Aeronautical Science and Technology,2010,21(5):2-6. doi: 10.3969/j.issn.1007-5453.2010.05.001 [2] HARRISON N, VASSBERG J, DEHAAN M, et al. The design and test of a swept wing upper surface blowing concept[C]// Proc of the 51st AIAA Aerospace Sciences Meeting. 2013. doi: 10.2514/6.2013-1102 [3] YADLIN Y, SHMILOVICH A. Lift enhancement for upper surface blowing airplanes[C]//Proc of the 31st AIAA Applied Aerodynamics Conference. 2013. doi: 10.2514/6.2013-2796 [4] JENNETTE T L,AHUJA K K. Noise source location and scaling of subsonic upper-surface blowing[J]. International Journal of Aeroa-coustics,2020,19(3-5):191-206. doi: 10.1177/1475472x20930652 [5] YAMATO H,OKADA N,BANDO T. Flight test of the Japanese up-per surface blowing STOL experimental aircraft ASKA[J]. Journal of Aircraft,1991,28(10):630-637. doi: 10.2514/3.46075 [6] RUMSEY C L,NISHINO T. Numerical study comparing RANS and LES approaches on a circulation control airfoil[J]. International Journal of Heat and Fluid Flow,2011,32(5):847-864. doi: 10.1016/j.ijheatfluidflow.2011.06.011 [7] WIMPRESS J K. Upper surface blowing technology as applied to the YC-14 airplane[C]// Proc of the SAE Technical Paper Series. 1973. doi: 10.4271/730916 [8] 赵国昌,邢仕廷,宋丽萍,等. 机翼上表面吹气动力增升简化模型[J]. 飞行力学,2018,36(4):39-43.ZHAO G C,XING S T,SONG L P,et al. Simplified model of wing upper surface blowing dynamic lift enhancement[J]. Flight Dyna-mics,2018,36(4):39-43. [9] XIAO T H,ZHU Z H,DENG S H,et al. Effects of nozzle geometry and active blowing on lift enhancement for upper surface blowing configuration[J]. Aerospace Science and Technology,2021,111:106536. doi: 10.1016/j.ast.2021.106536 [10] ZHU Z H, XIAO T H, ZHAI C, et al. Numerical study on lift enhancement for upper surface blowing system with powered turbofan engine[C]//Proc of the AIAA Aviation 2019 Forum. 2019. doi: 10.2514/6.2019-3167 [11] 章荣平,王勋年,黄勇,等. 低速风洞全模TPS试验空气桥的设计与优化[J]. 实验流体力学,2012,26(6):48-52. doi: 10.3969/j.issn.1672-9897.2012.06.011ZHANG R P,WANG X N,HUANG Y,et al. Design and optimi-zation of the air bridge for low speed full-span TPS test[J]. Journal of Experiments in Fluid Mechanics,2012,26(6):48-52. doi: 10.3969/j.issn.1672-9897.2012.06.011 [12] 巫朝君,胡卜元,李东,等. 扁平融合式飞机整体式进/排气试验的推/阻校准方法[J]. 实验流体力学,2019,33(5):88-93. doi: 10.11729/syltlx20180141WU C J,HU B Y,LI D,et al. Thrust/drag calibrations for integral inlet and jet testing on a aircraft with blended wing/body[J]. Journal of Experiments in Fluid Mechanics,2019,33(5):88-93. doi: 10.11729/syltlx20180141 [13] 郝礼书,乔志德,宋文萍. 涡流发生器布局方式对翼型失速流动控制效果影响的实验研究[J]. 西北工业大学学报,2011,29(4):524-528. doi: 10.3969/j.issn.1000-2758.2011.04.005HAO L S,QIAO Z D,SONG W P. Experimentally studying effects of different layouts of vortex generator on controlling stall flow over airfoil[J]. Journal of Northwestern Polytechnical University,2011,29(4):524-528. doi: 10.3969/j.issn.1000-2758.2011.04.005 [14] 李宝山,龚玉祥,张建军,等. 涡流发生器高度和长度对风力机翼型的影响研究[J]. 机电工程技术,2020,49(11):148-150. doi: 10.3969/j.issn.1009-9492.2020.11.044LI B S,GONG Y X,ZHANG J J,et al. Research on the influence of height and length of vortex generators on wind turbine airfoil[J]. Mechanical & Electrical Engineering Technology,2020,49(11):148-150. doi: 10.3969/j.issn.1009-9492.2020.11.044 -

下载:

下载: