Wind tunnel experimental study on aerodynamics and noise based on the influence of automobile rearview mirror shapes

-

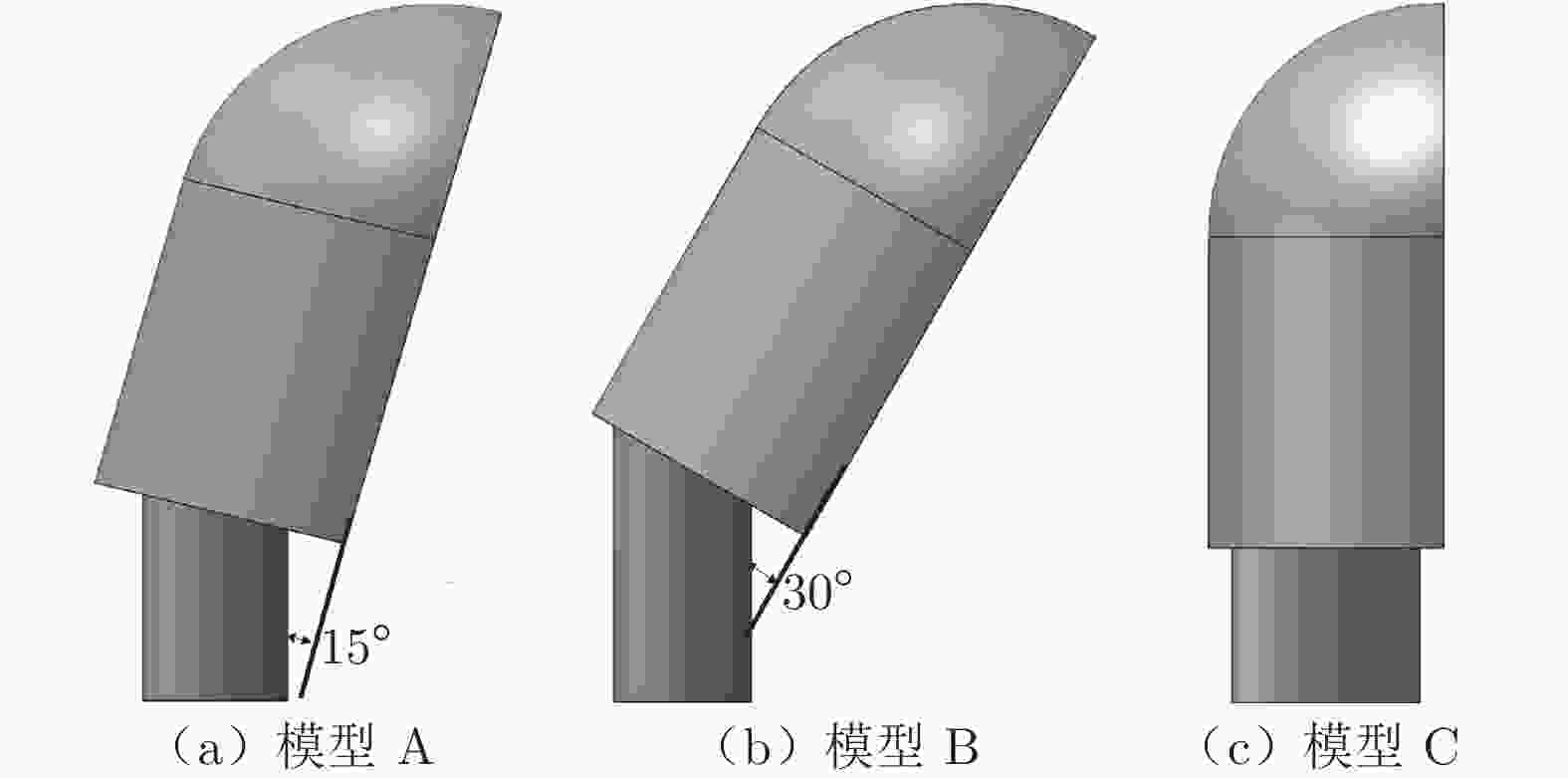

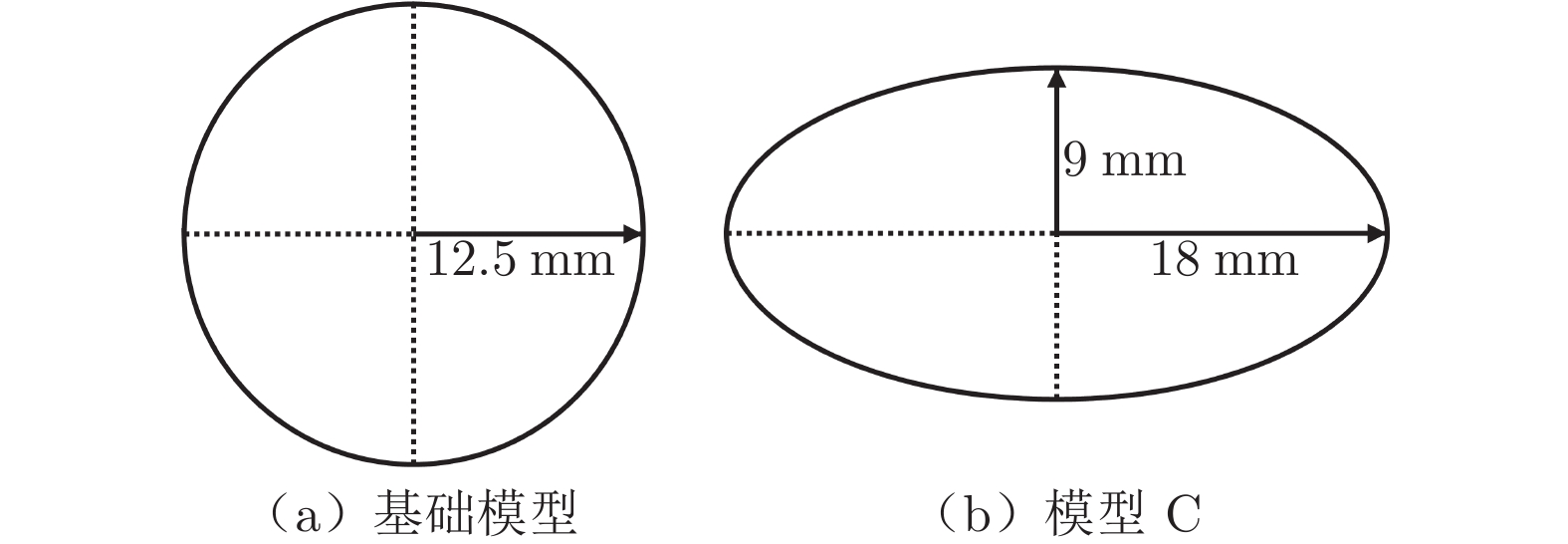

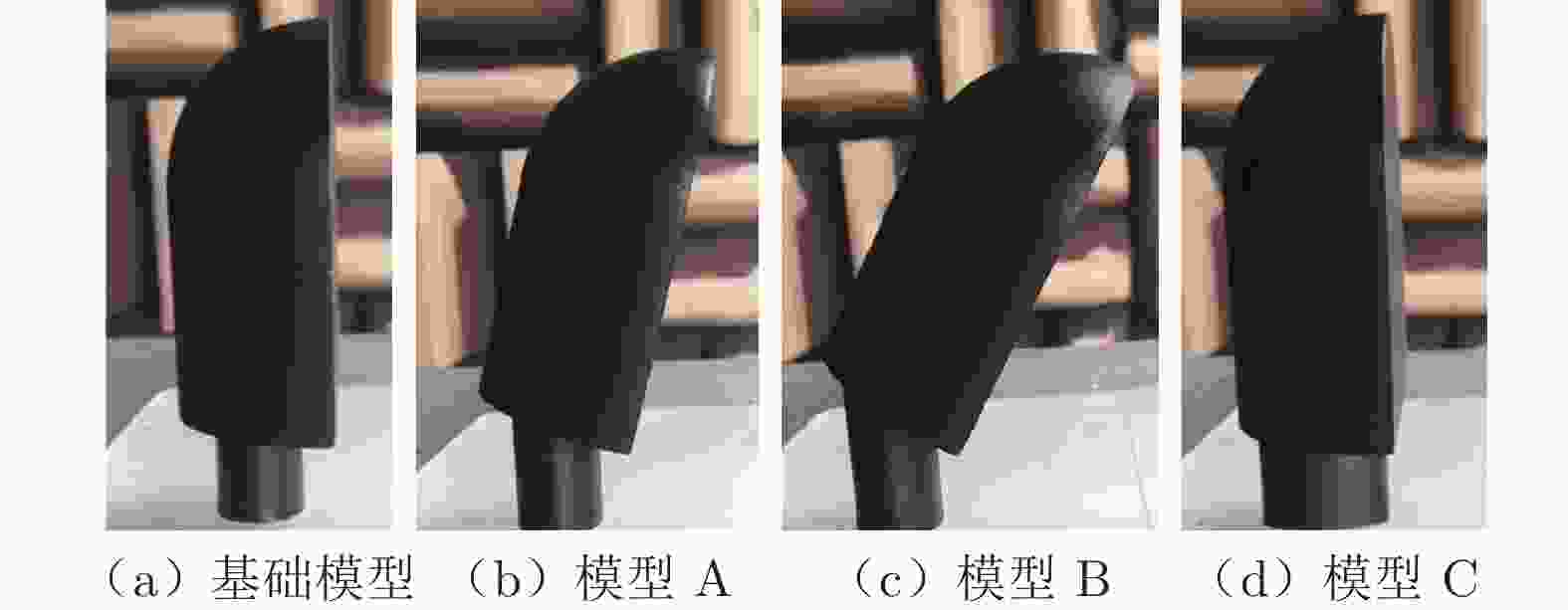

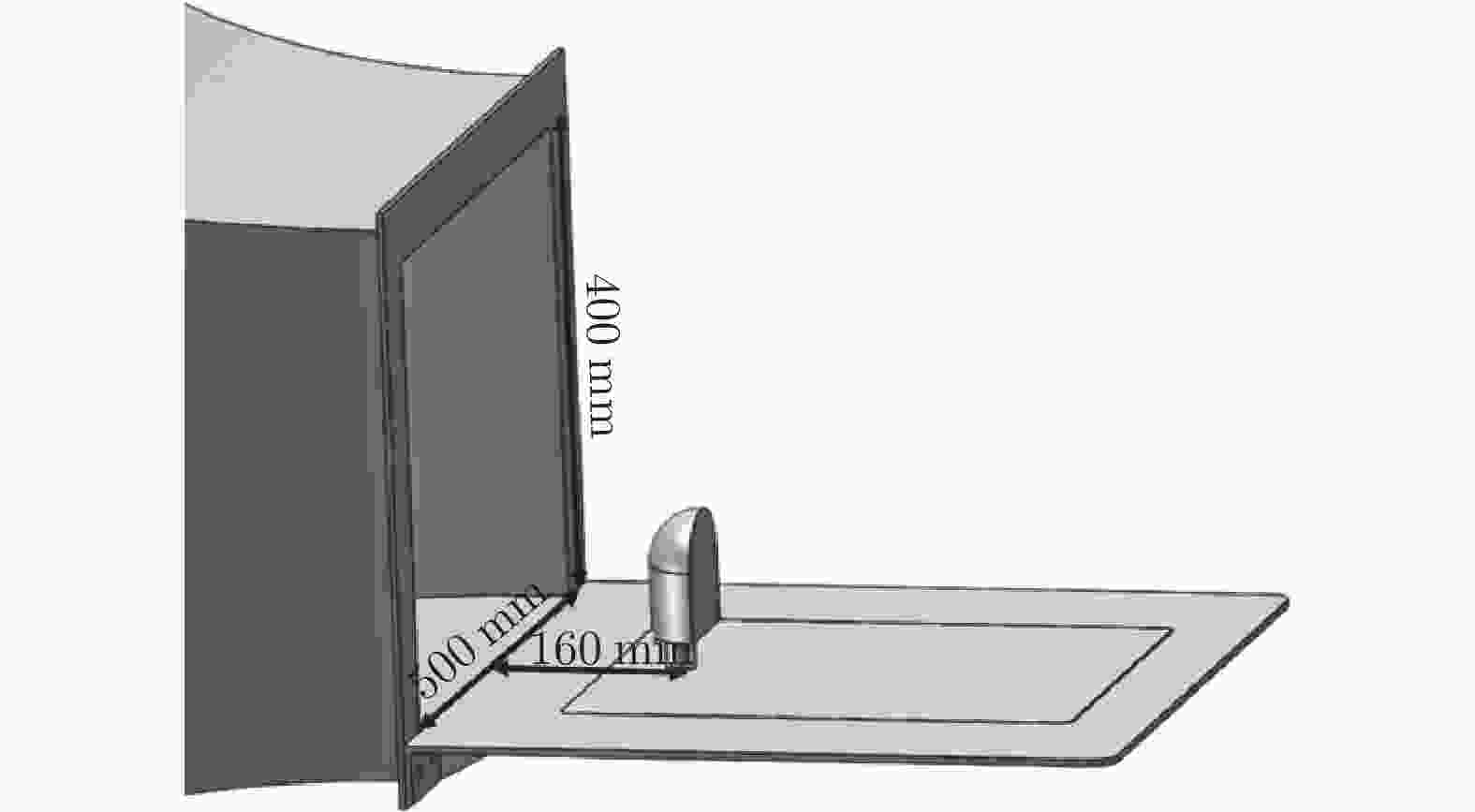

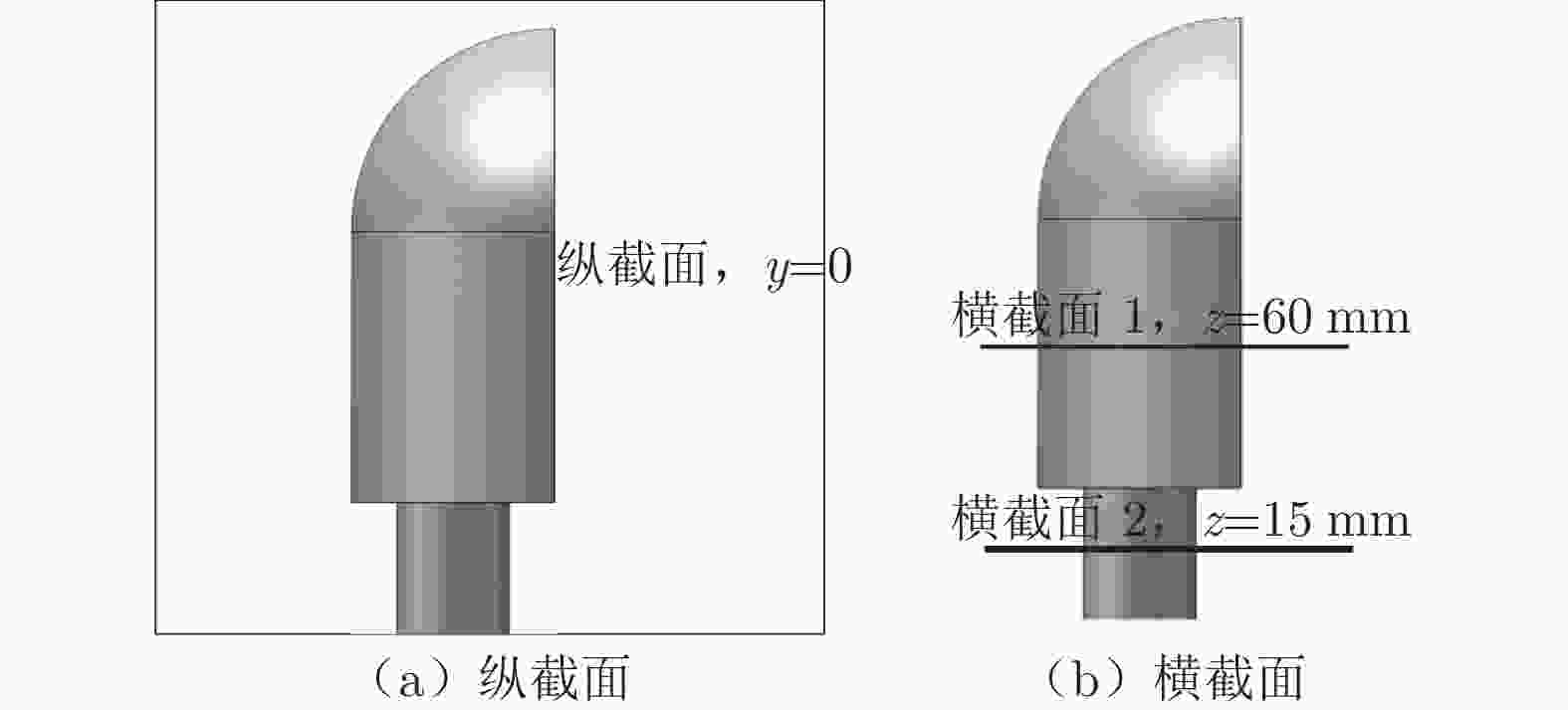

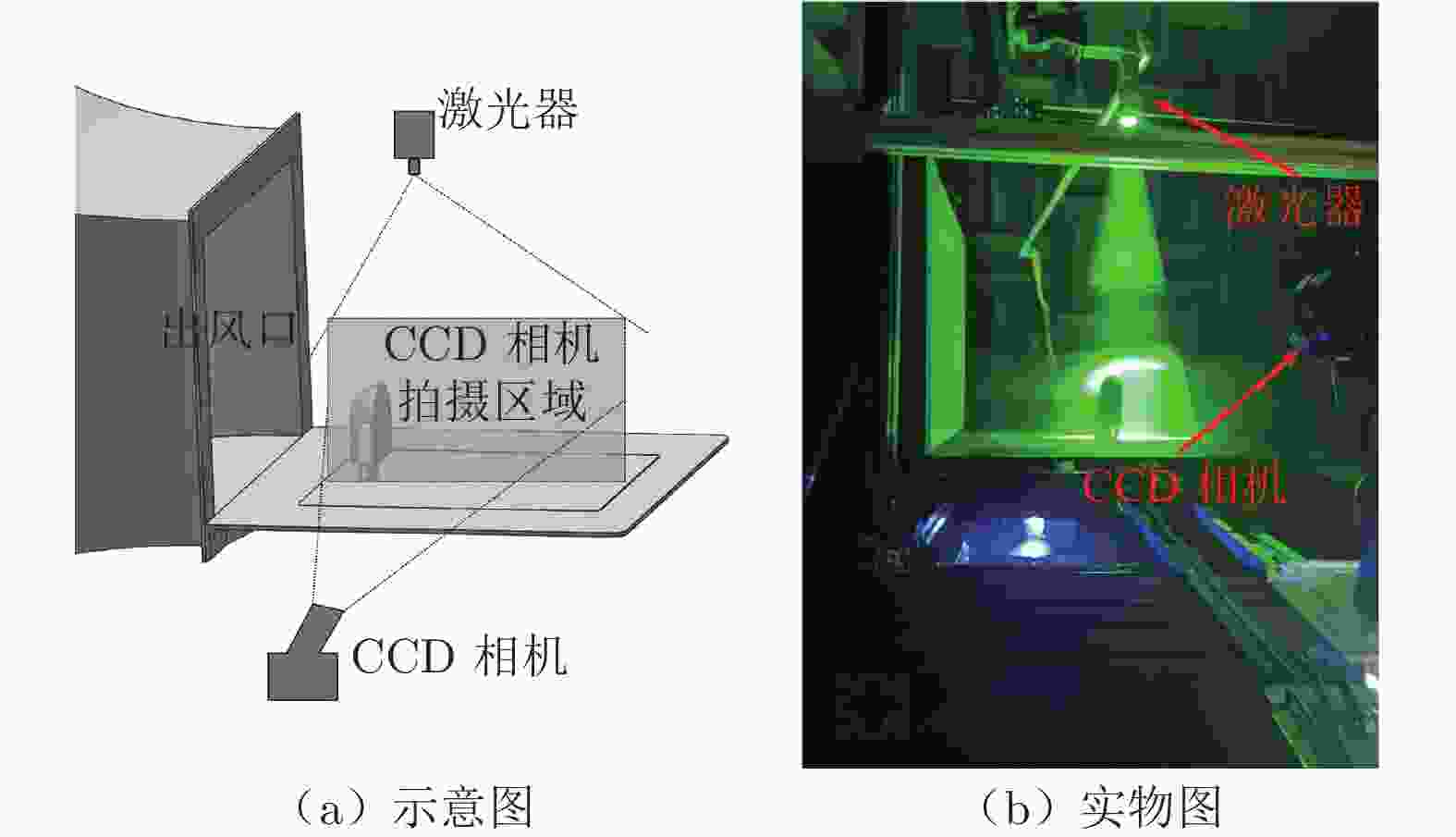

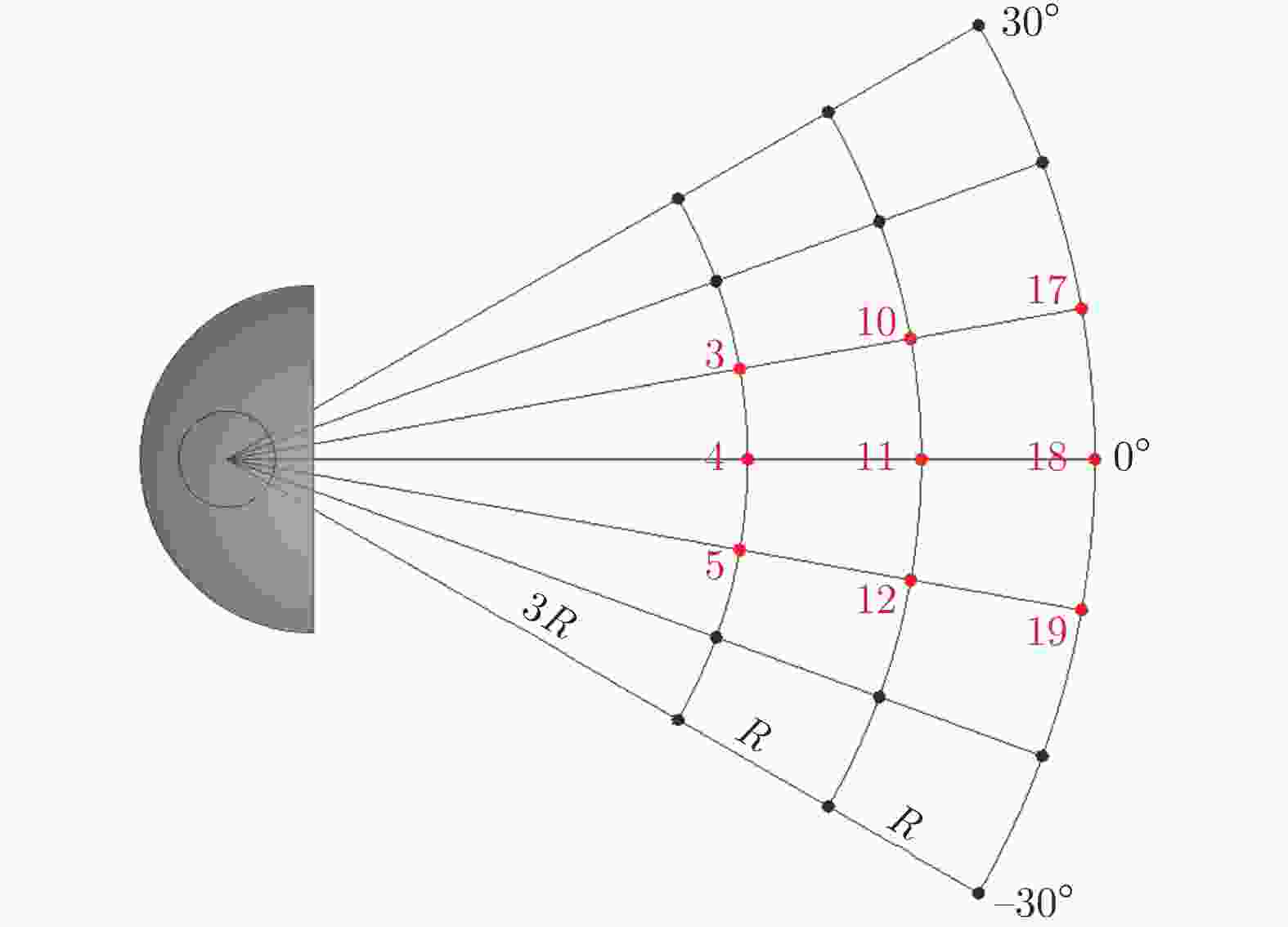

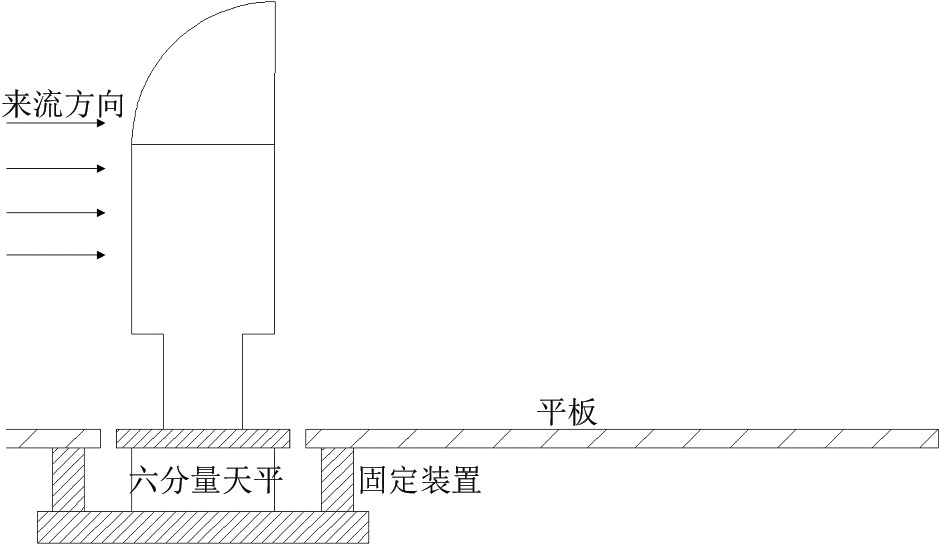

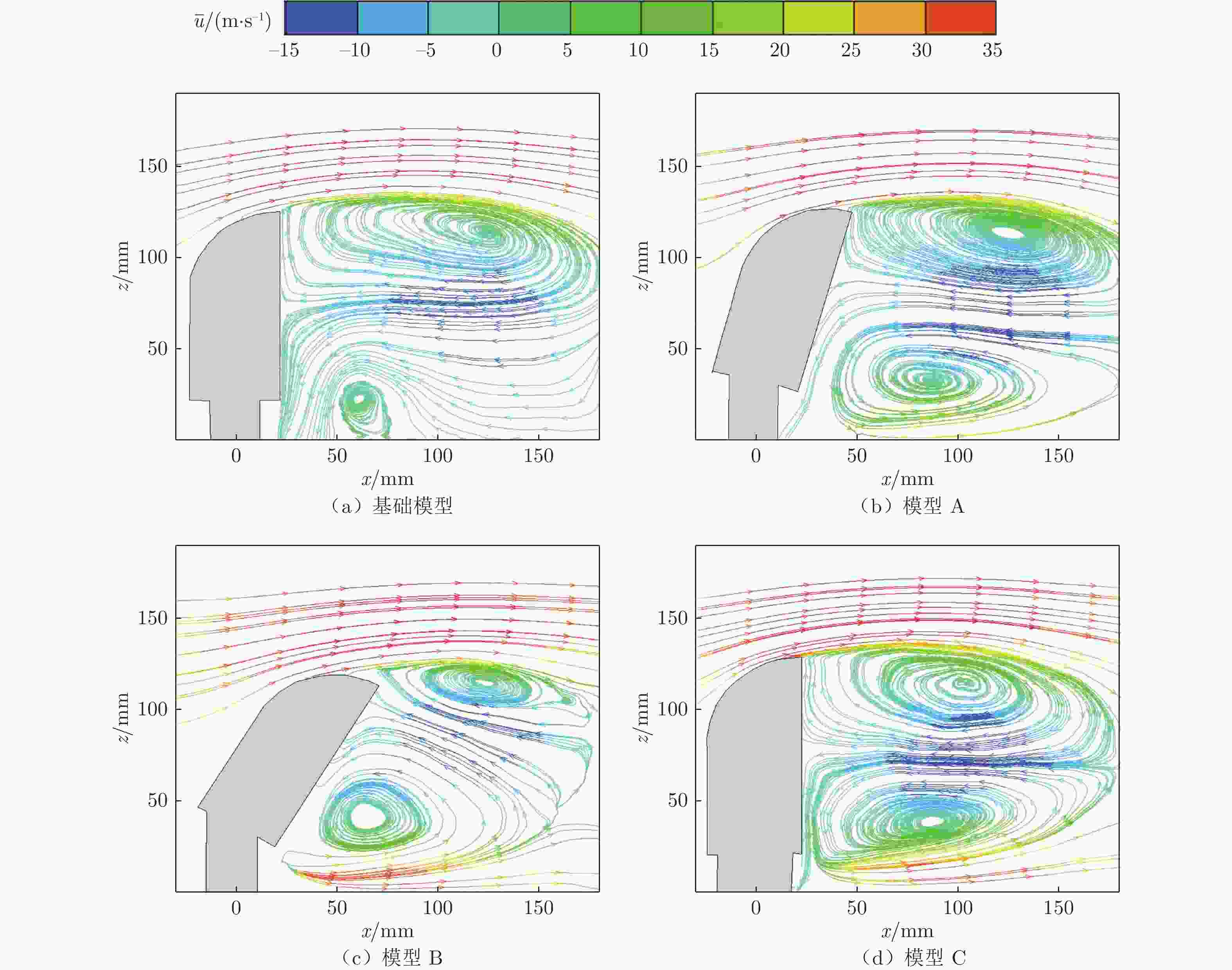

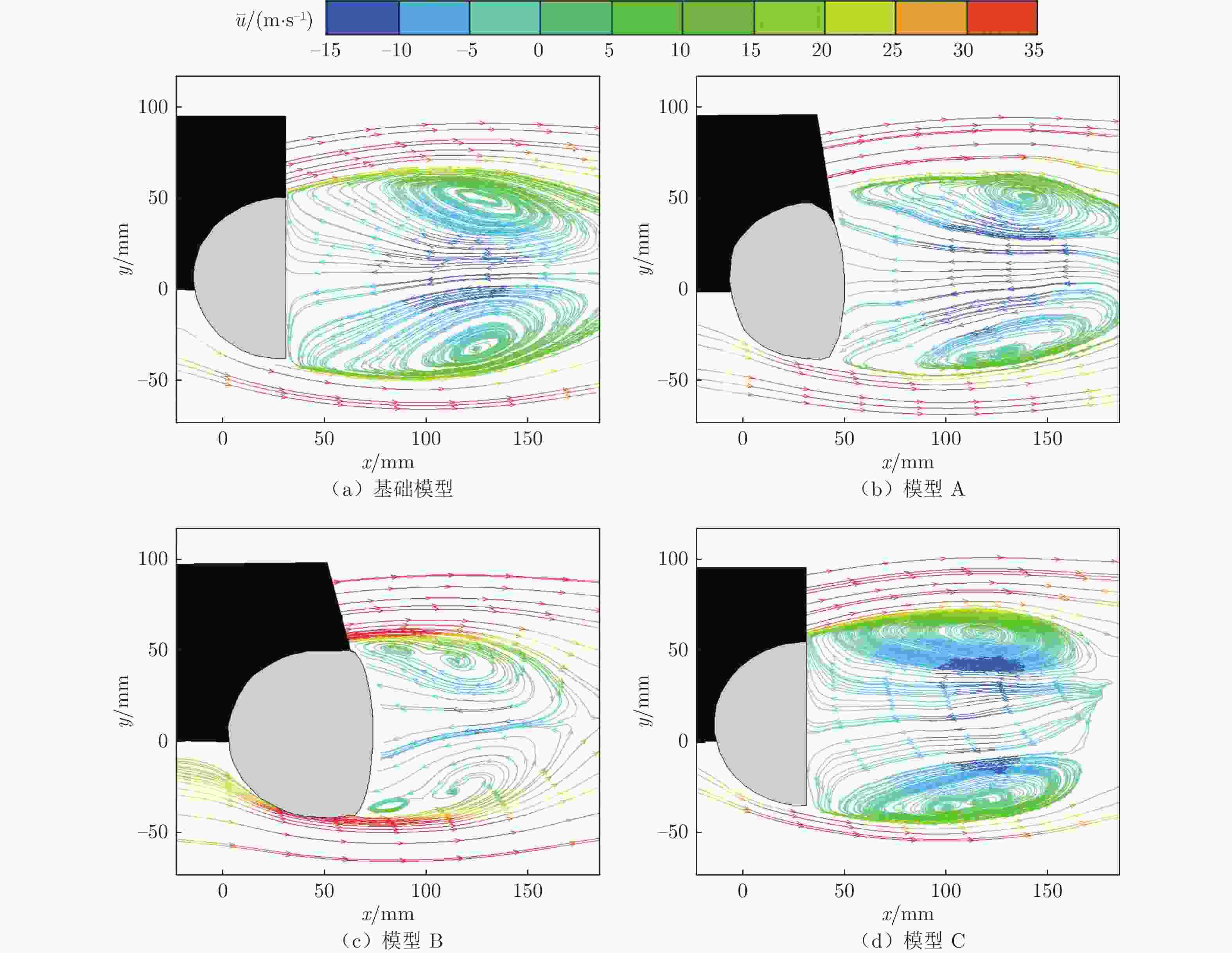

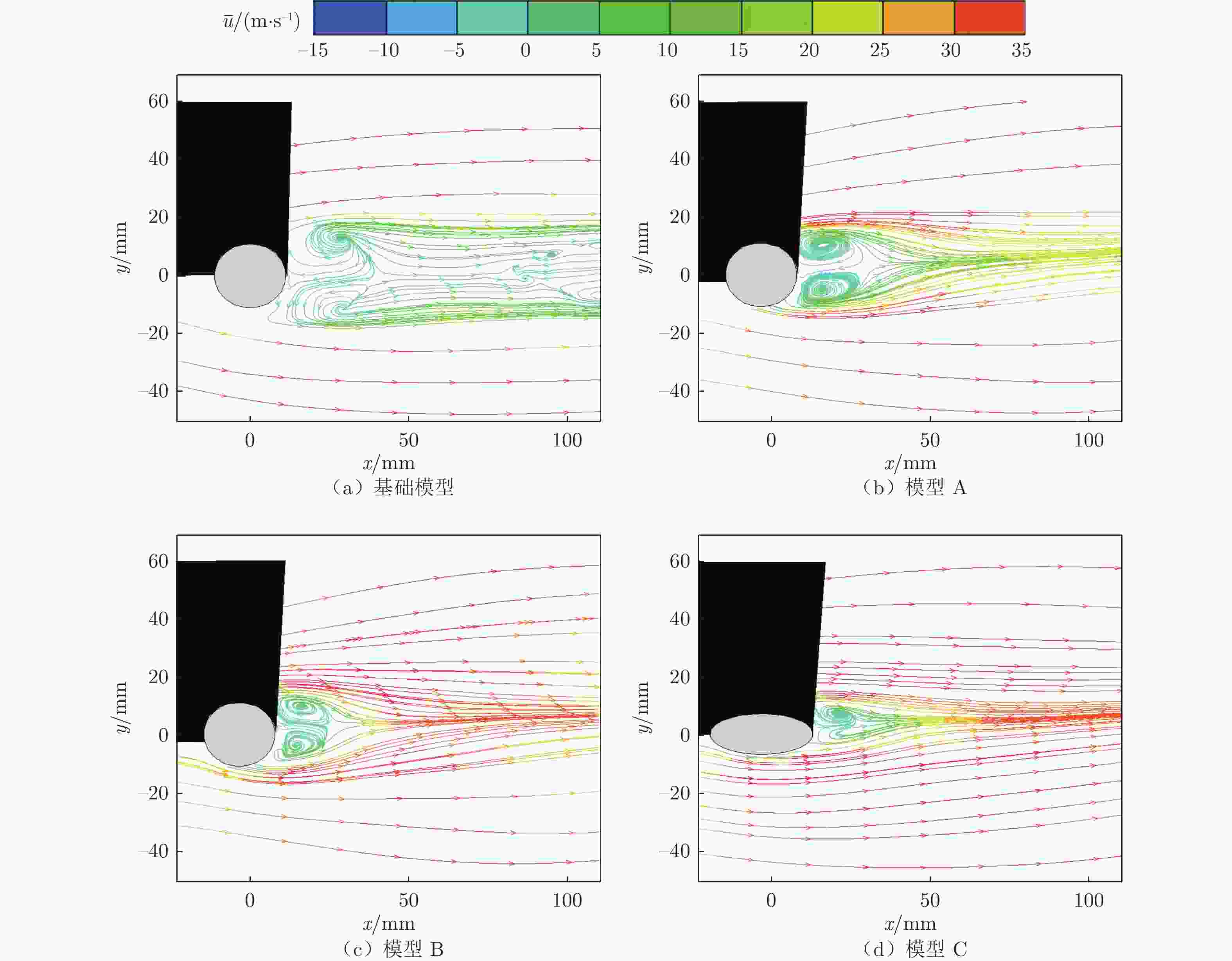

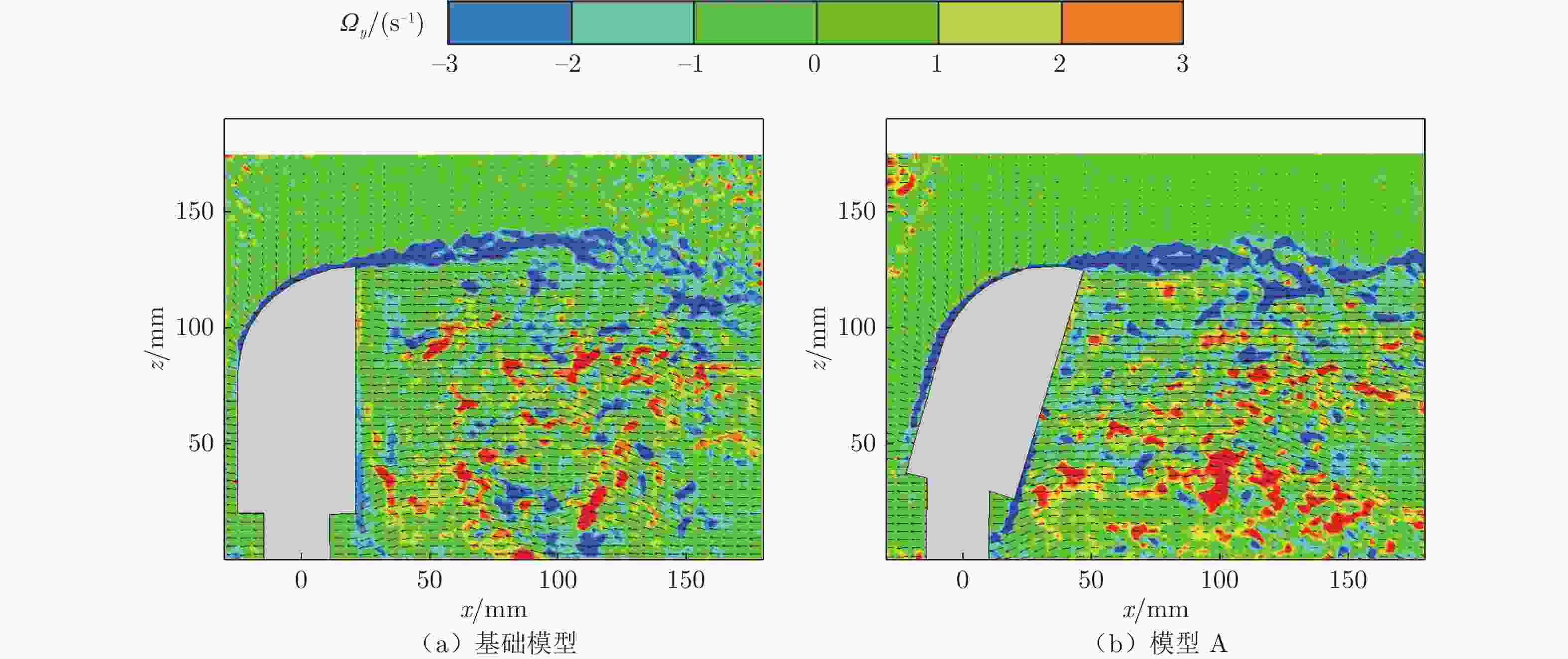

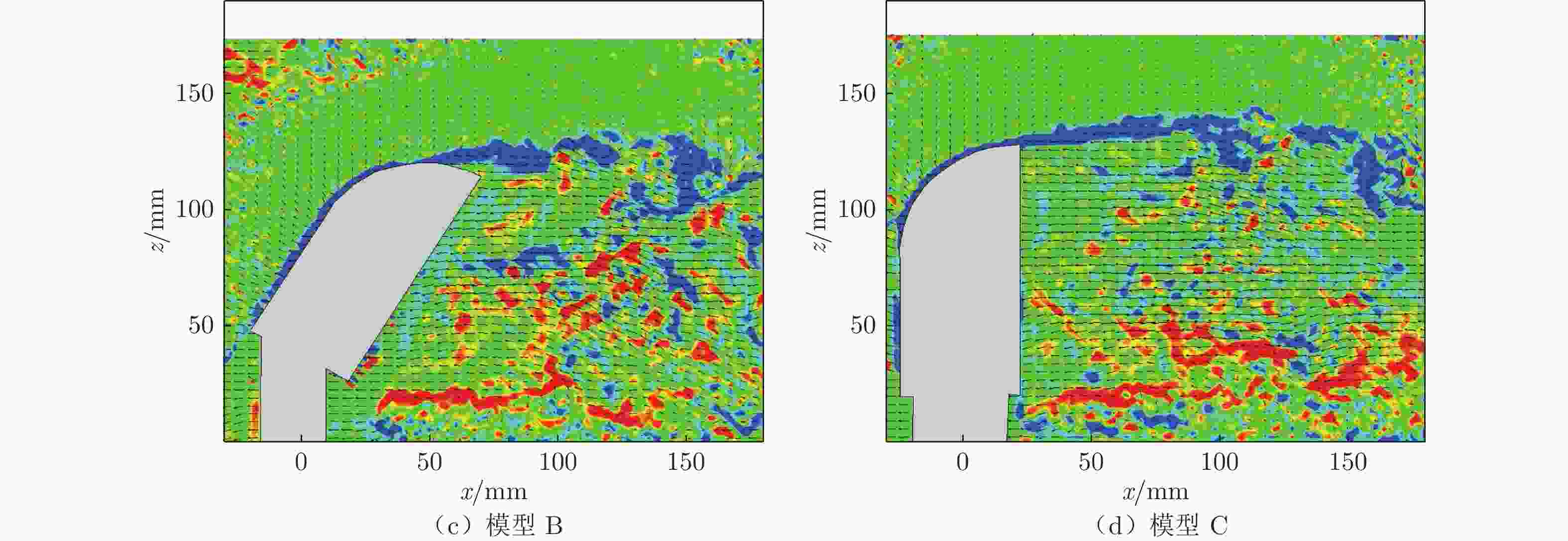

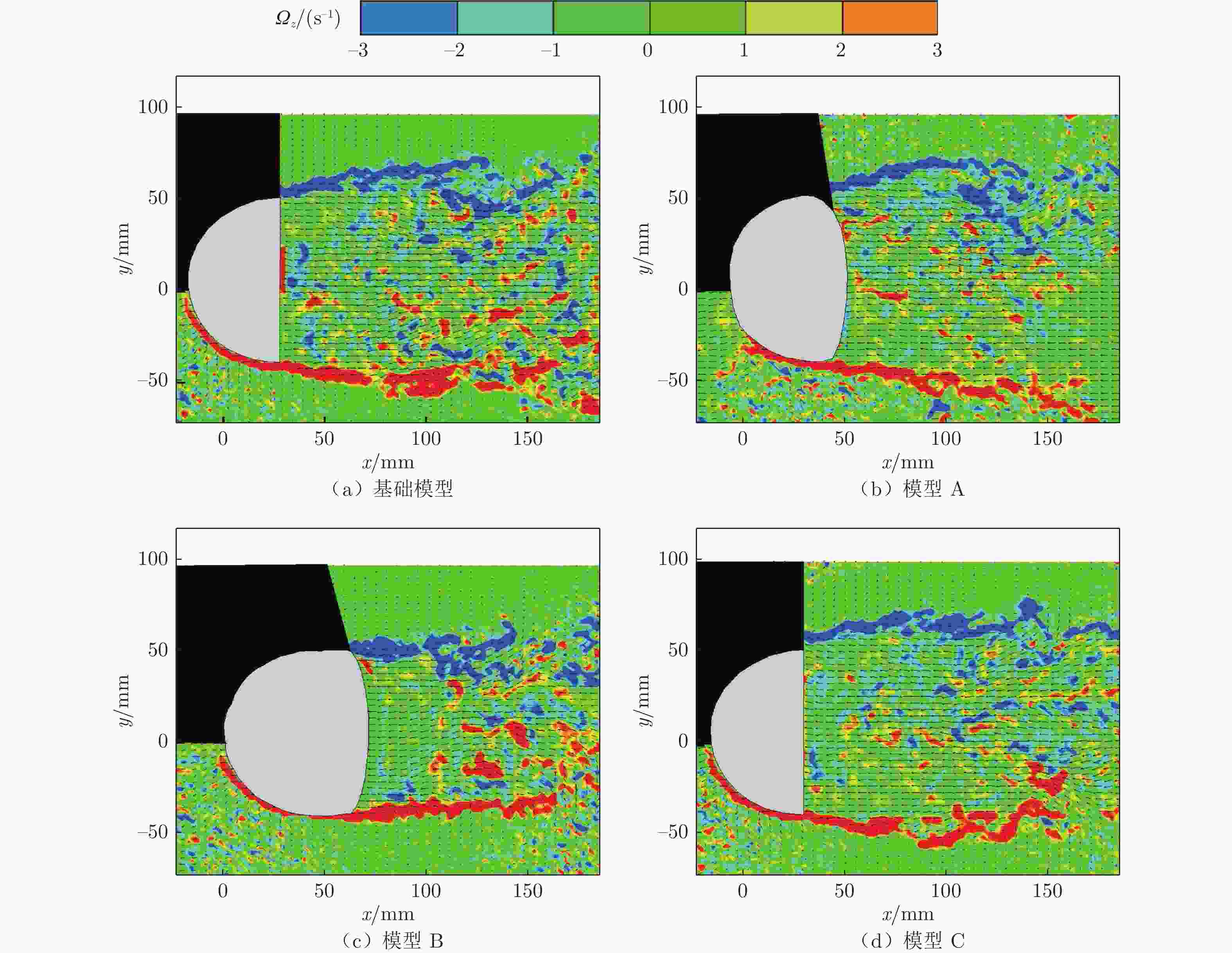

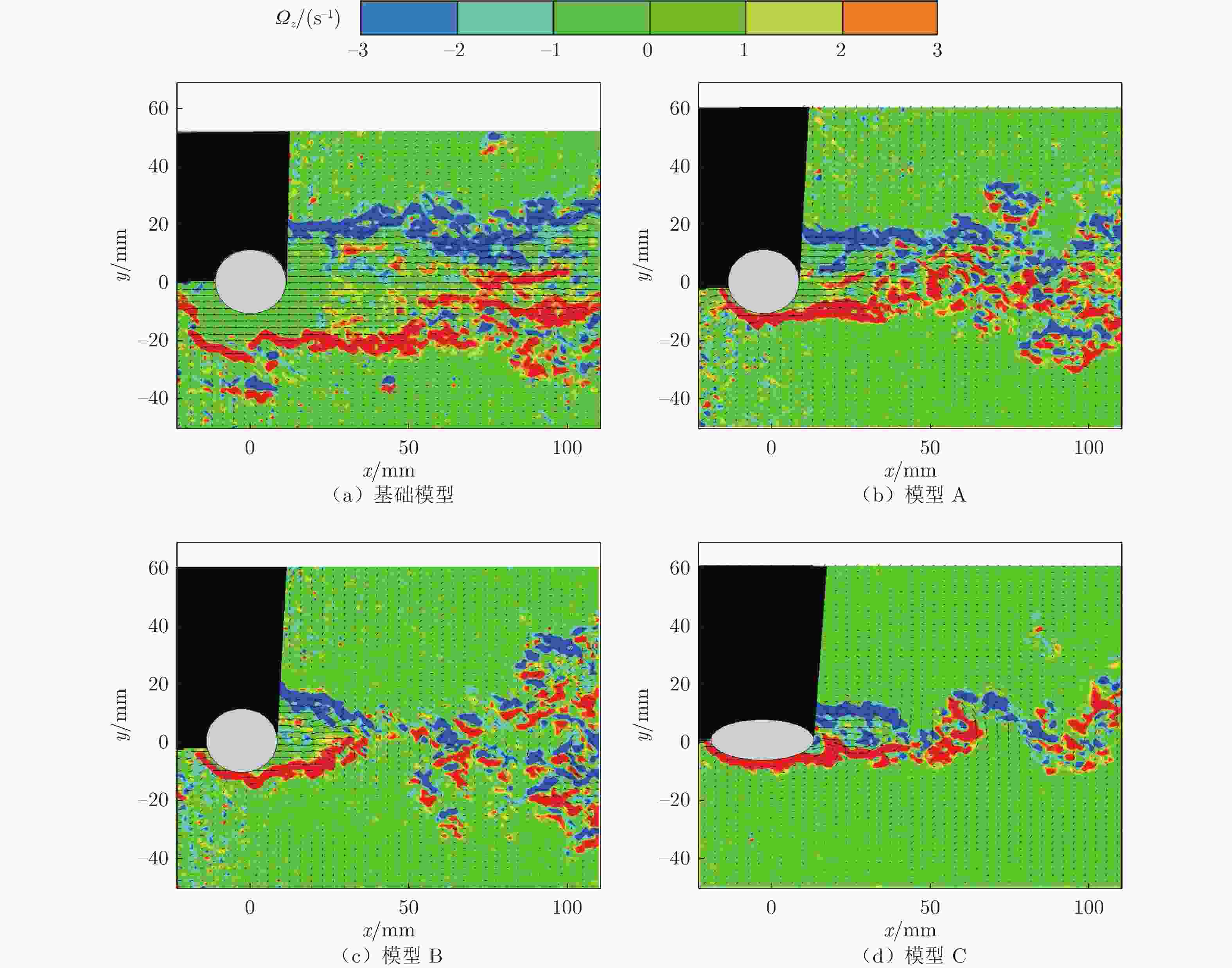

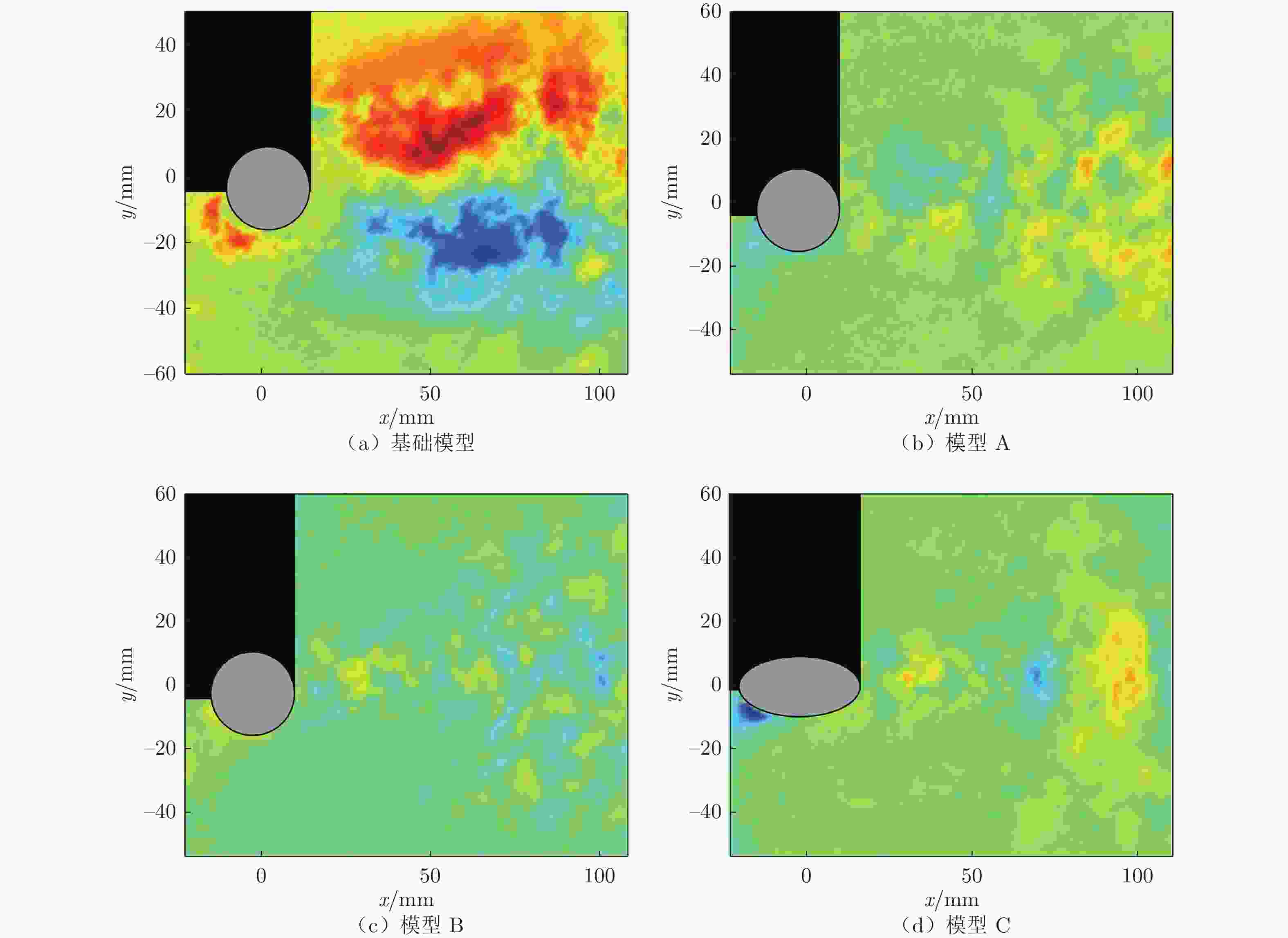

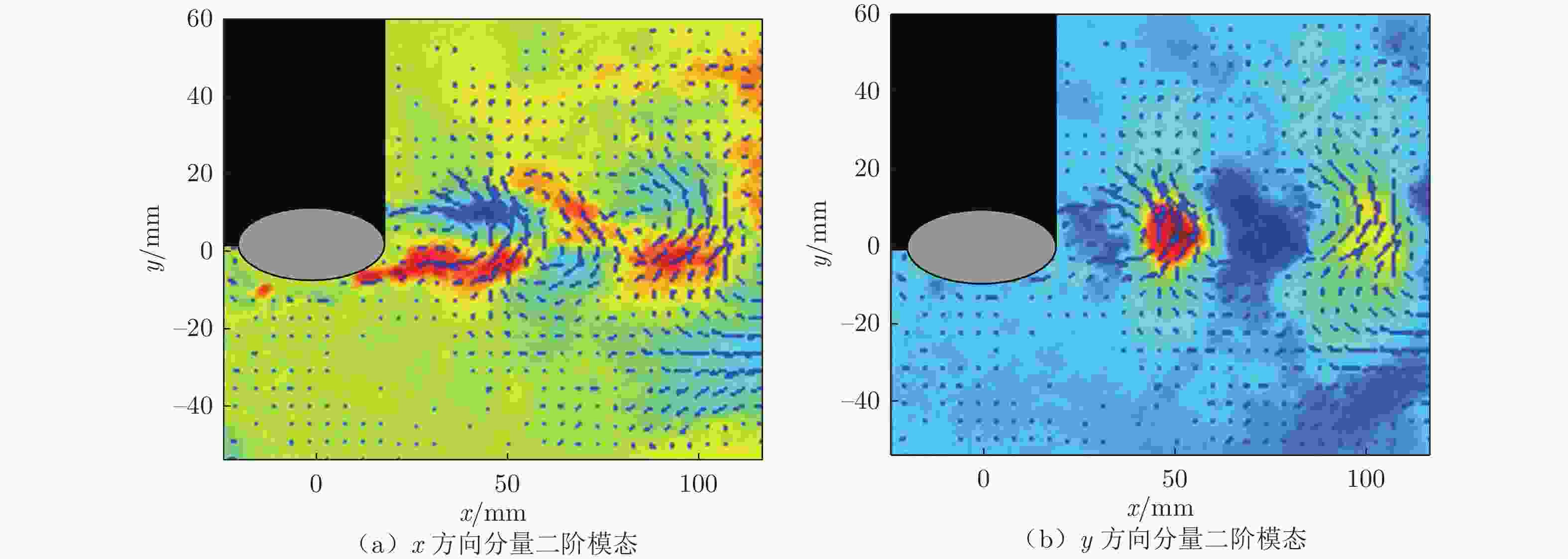

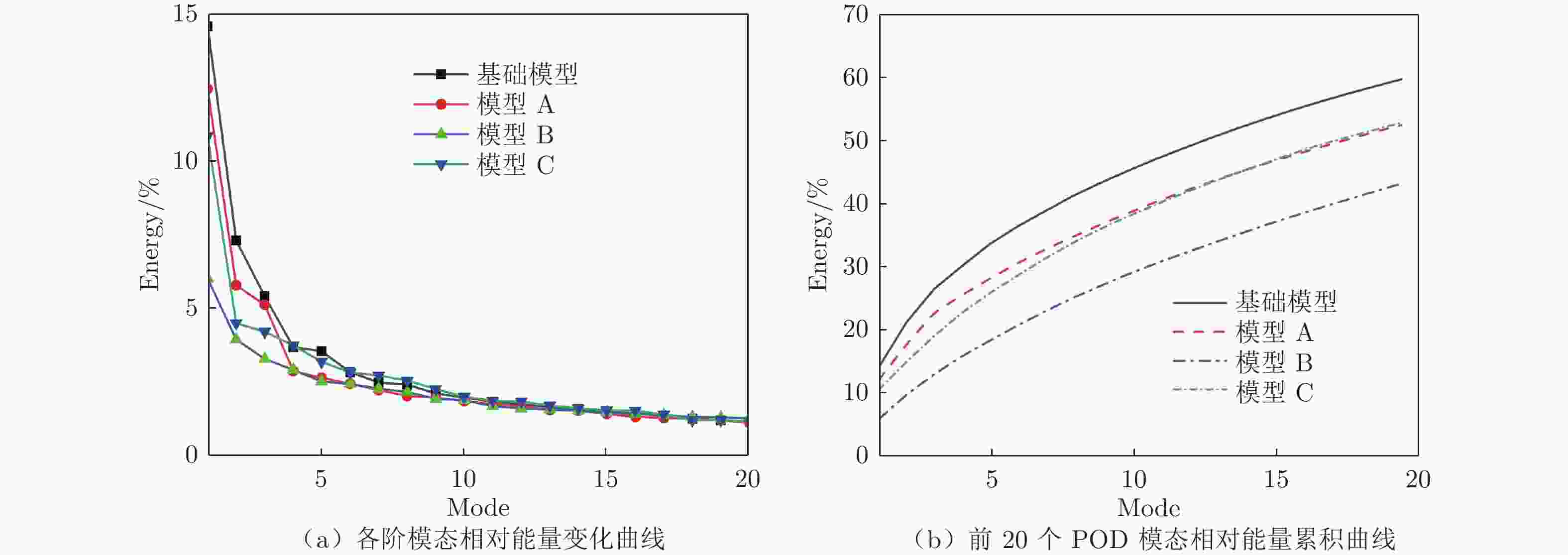

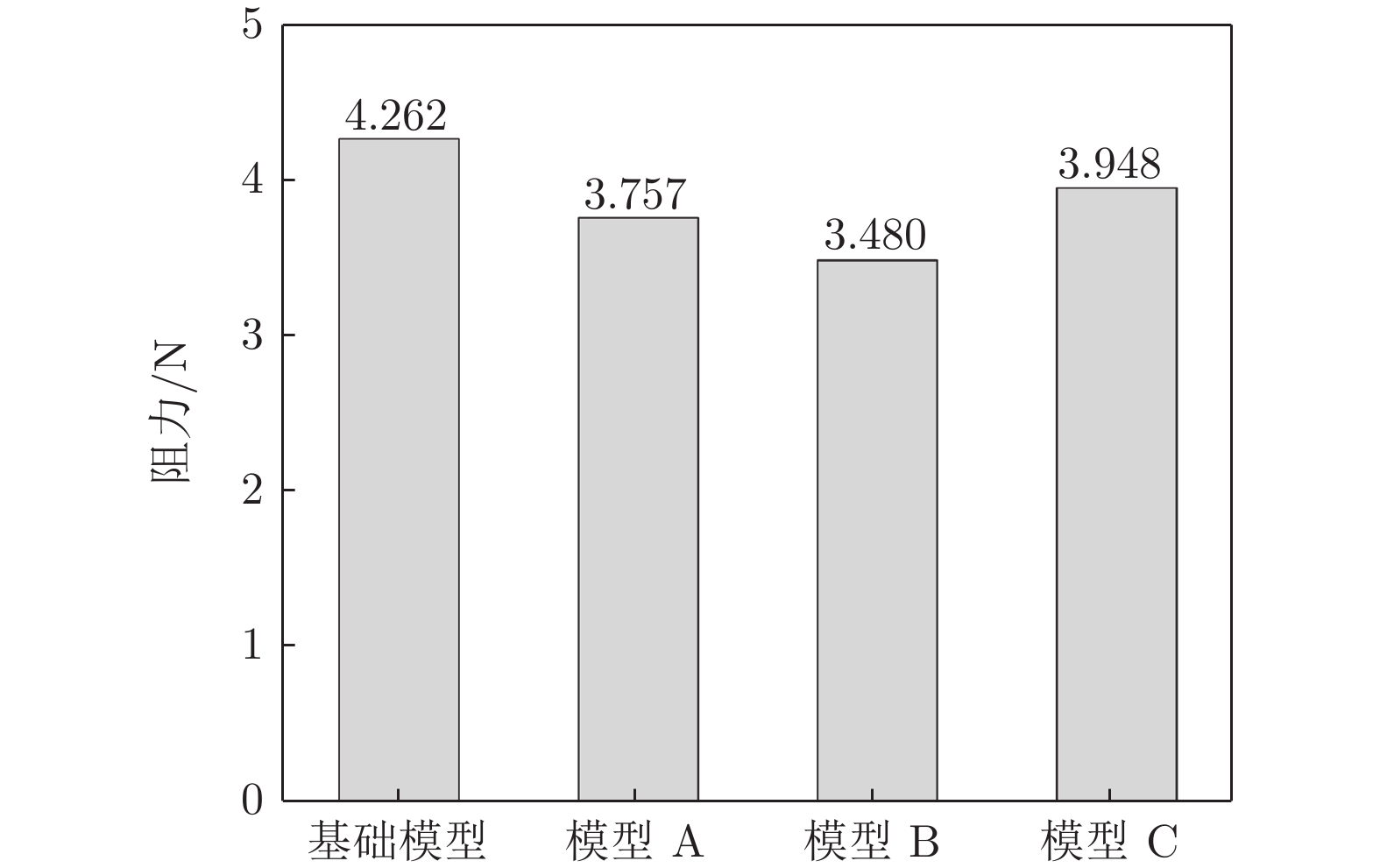

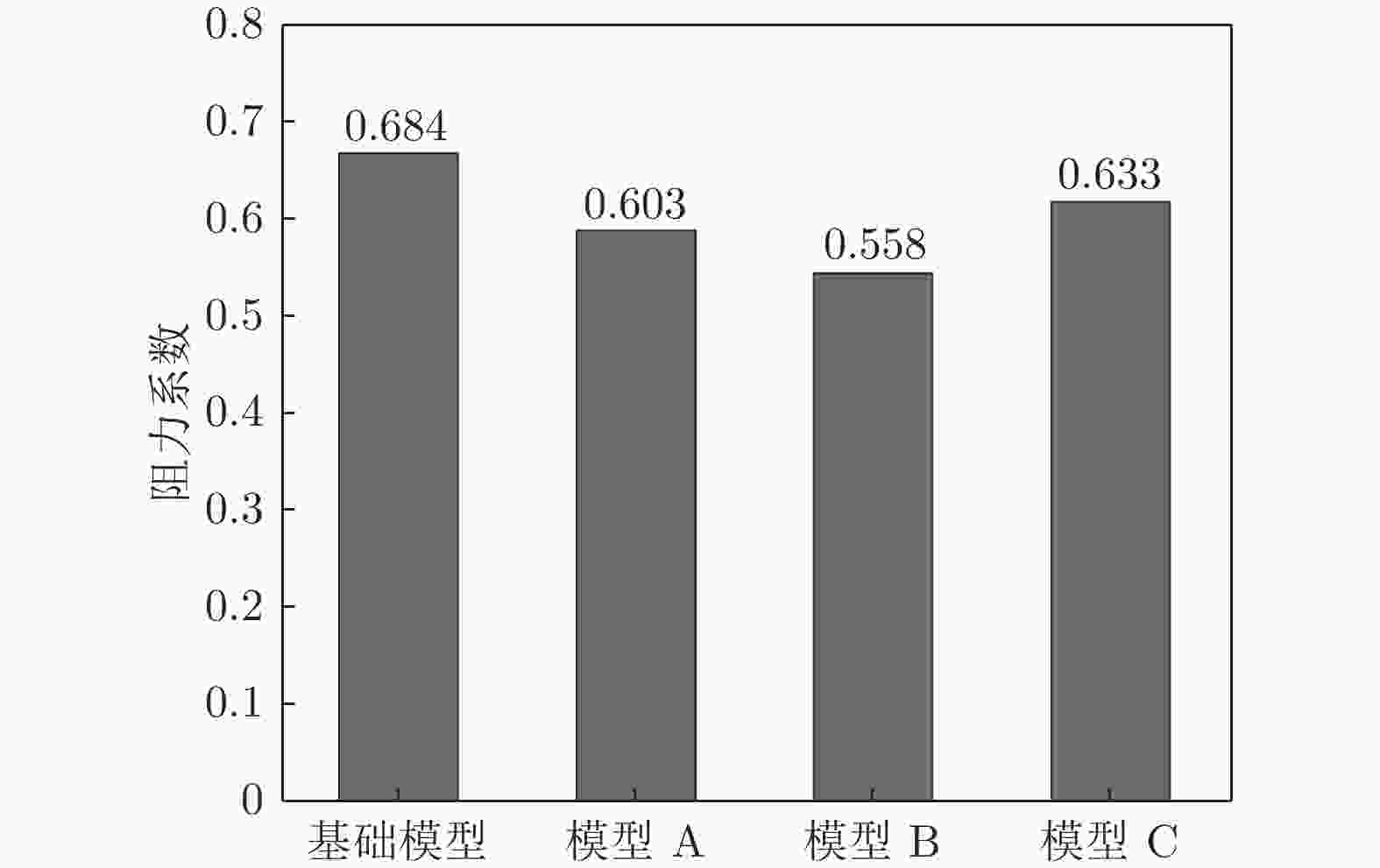

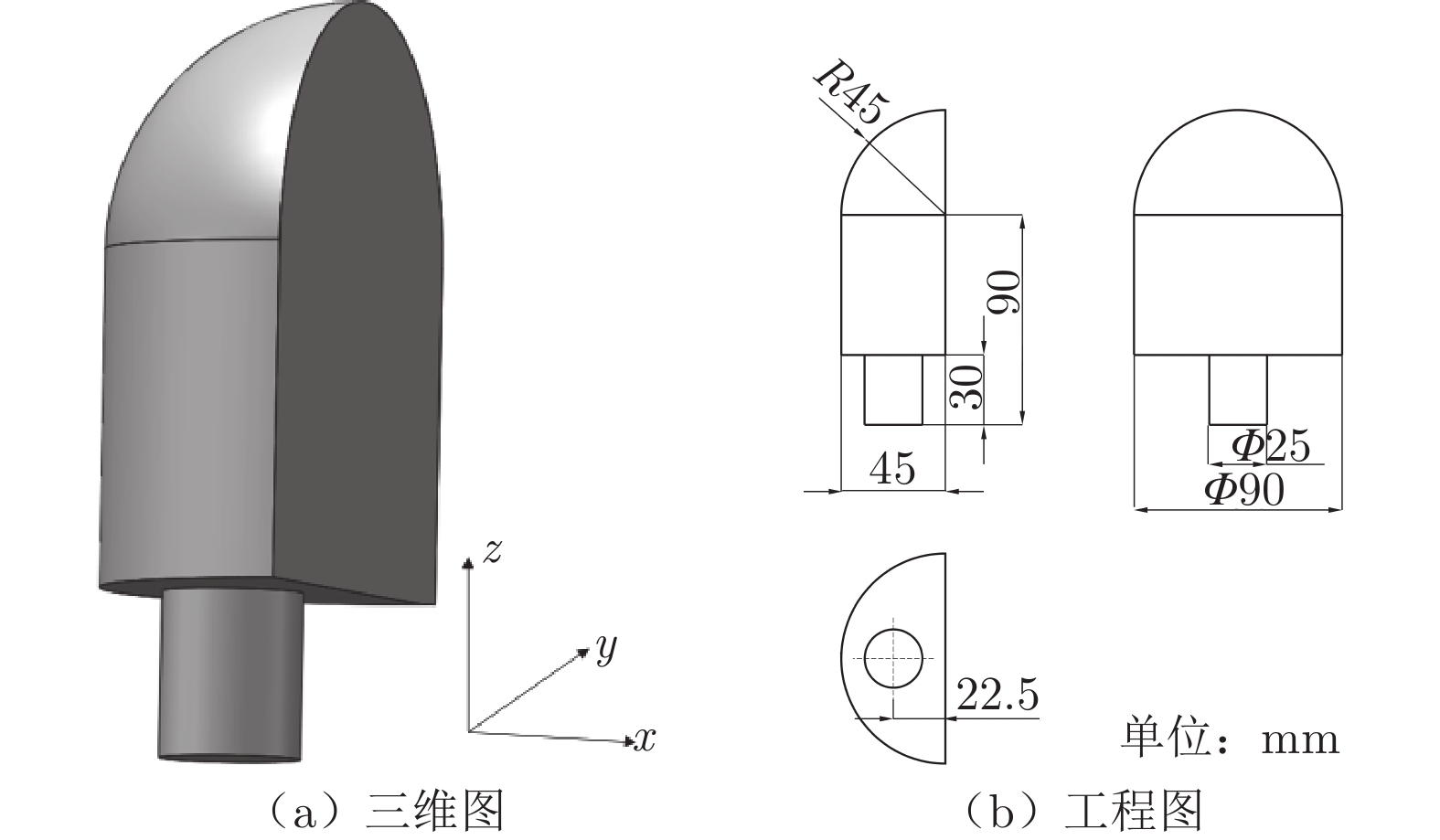

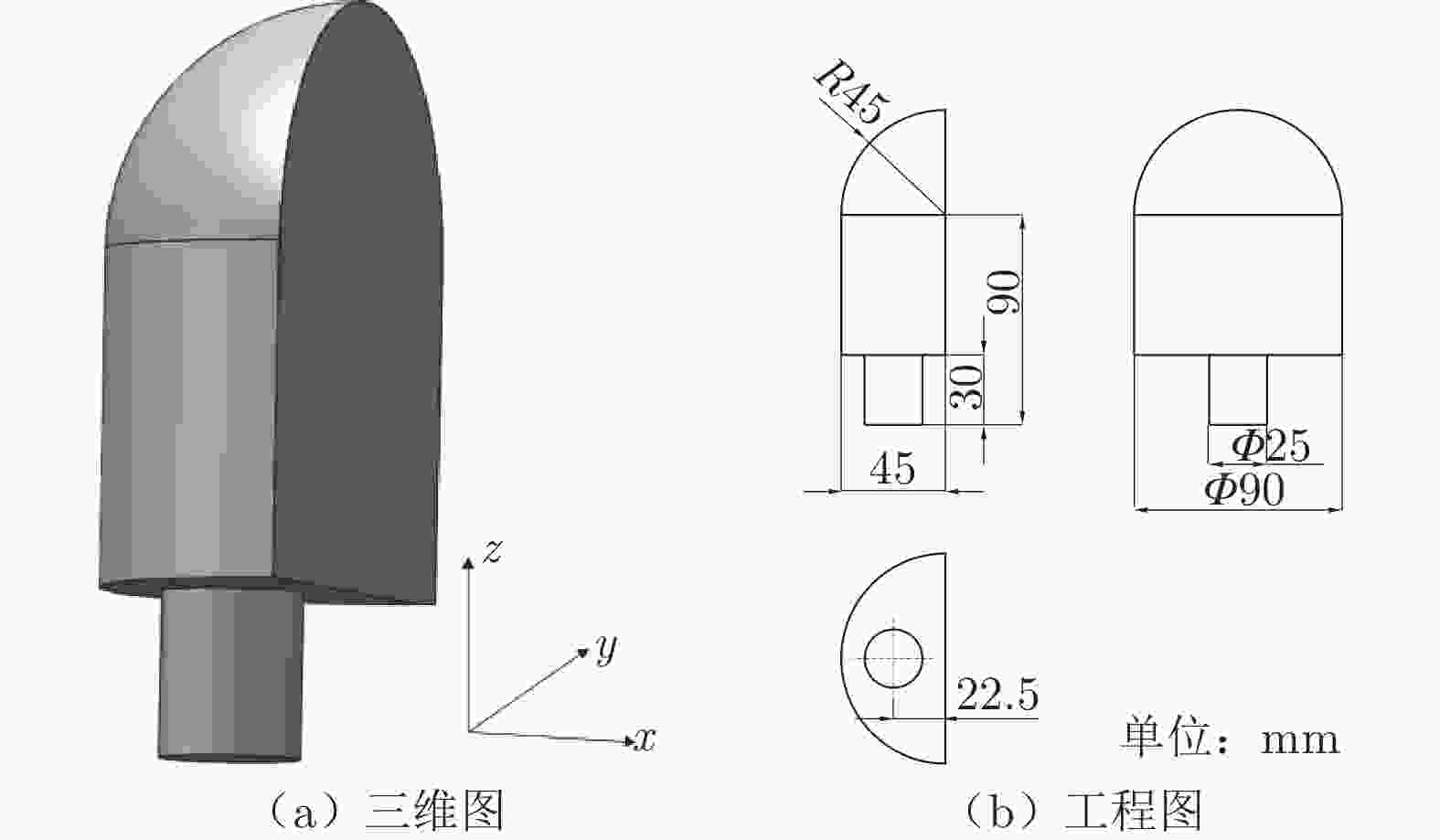

摘要: 为降低由汽车后视镜带来的气动噪声,本文以一简化汽车外后视镜模型为基础模型,提出3个不同造型改进方案:A造型模型镜身倾斜15°;B造型模型镜身倾斜30°;C造型模型将原圆柱形底座改为椭柱形底座。对4款造型外后视镜模型进行风洞实验研究,分析流场、空气阻力和壁面脉动压力随造型改变的规律。气动特性(流场和阻力)采用粒子图像测速仪 (PIV) 和六分量动态天平测量,声学特性采用壁面麦克风对侧窗平板的湍流脉动进行测量。研究结果表明:3个造型改进方案均可在不同程度上改善外后视镜尾迹区域流场品质,有效降低空气阻力和气动噪声。其中B模型阻力系数较基础模型降低18.4%,壁面脉动压力总声压级在中低频段可降低4.6 dB;C模型可降低阻力系数7.5%,总声压级可降低4.3 dB。Abstract: To reduce the aerodynamic noise caused by automobile rearview mirrors, a simplified rearview mirror model was taken as the research object, and three different modeling improvement schemes were proposed: model A tilts the mirror body at 15°; model B tilts the mirror body at 30°; model C changes the cylindrical base to an elliptical base. Wind tunnel experiments were carried out on the models to analyze the variation rules of the flow field, drag, and wall pressure fluctuation with the change of the model. The particle image velocimetry (PIV) and six-component balance were used to measure the aerodynamic characteristics including the flow field and drag, and the wall microphone was applied to measure the acoustic characteristics. The results show that all three schemes can improve the flow quality in the wake area of the rearview mirror, effectively reducing the drag and the generation of aerodynamic noise. Compared to the base model, the drag coefficient and the overall sound pressure level of the wall pressure fluctuation of model B can be reduced by 18.4% and 4.6 dB in the low-mid frequency range. For model C, the corresponding results are 7.5% and 4.3 dB, respectively. The research results are beneficial for engineers in the aerodynamic and acoustic design of automobile rearview mirrors.

-

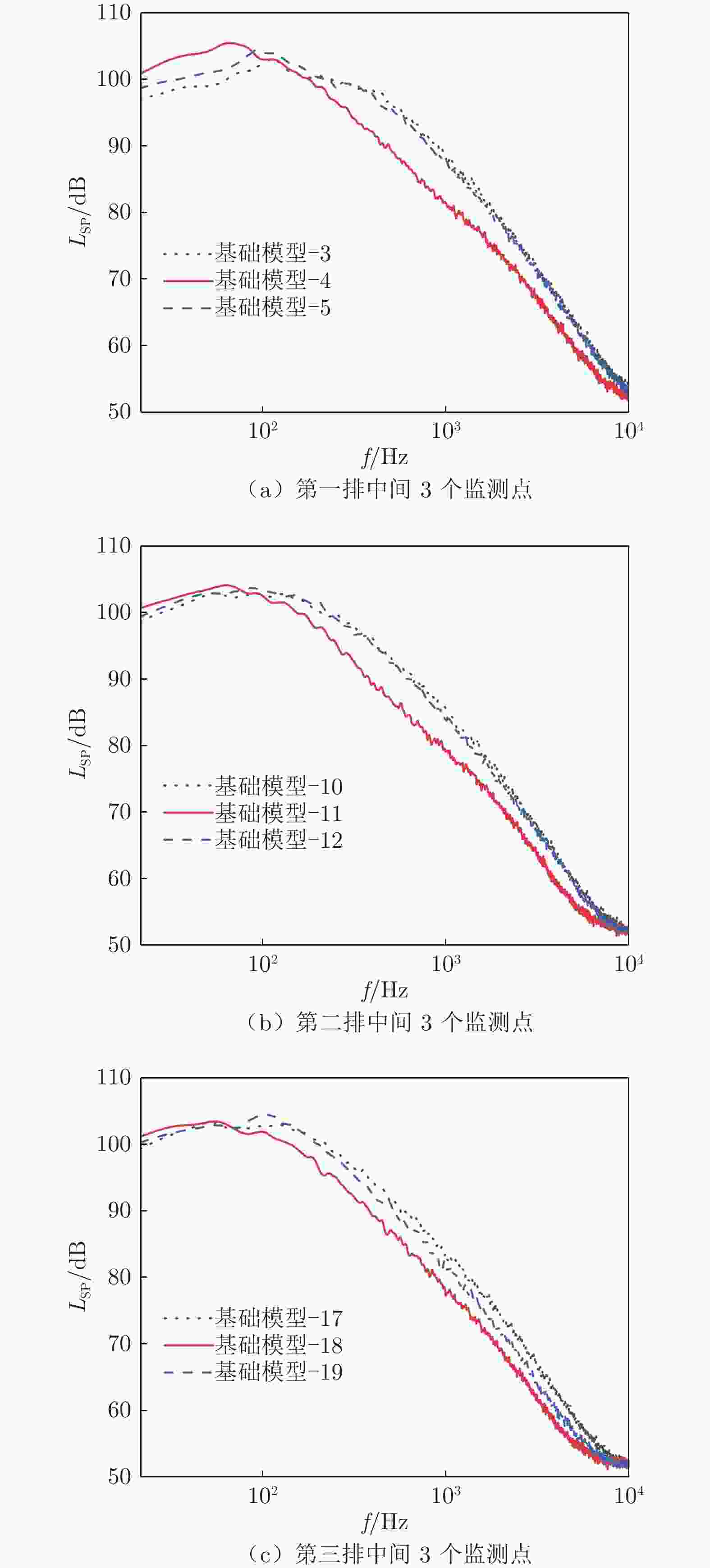

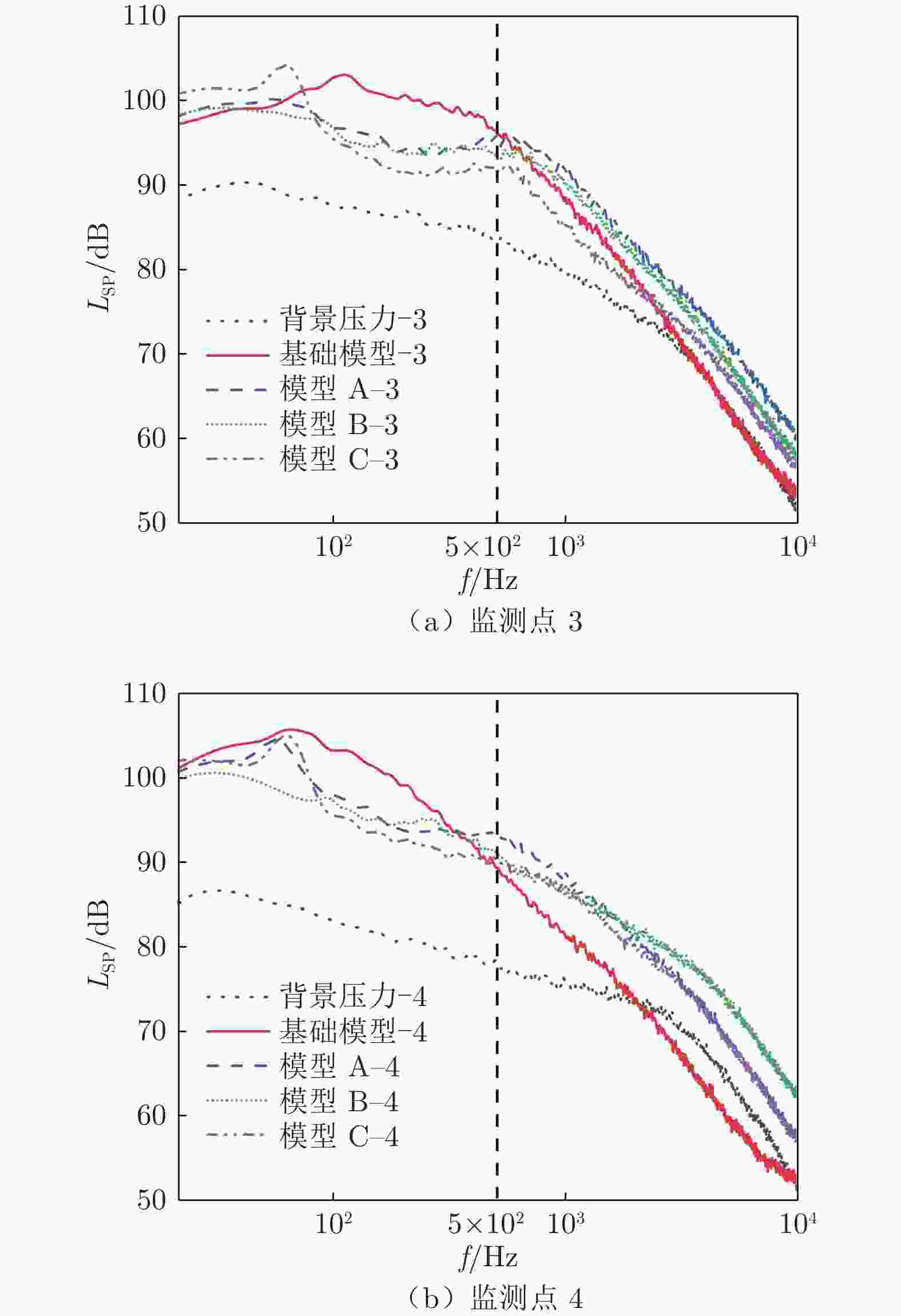

表 1 第一排3个监测点总声压级对照表

Table 1. Comparison table of overall sound pressure level of three monitoring points in the first row

单位:dB 监测点 3 4 5 背景压力 115.6 111.9 114.6 基础模型 127.4 126.4 127.6 模型 A 125.4 124.8 126.1 模型 B 124.3 123.8 124.7 模型 C 123.2 123.4 123.3 表 2 第二排3个监测点总声压级对照表

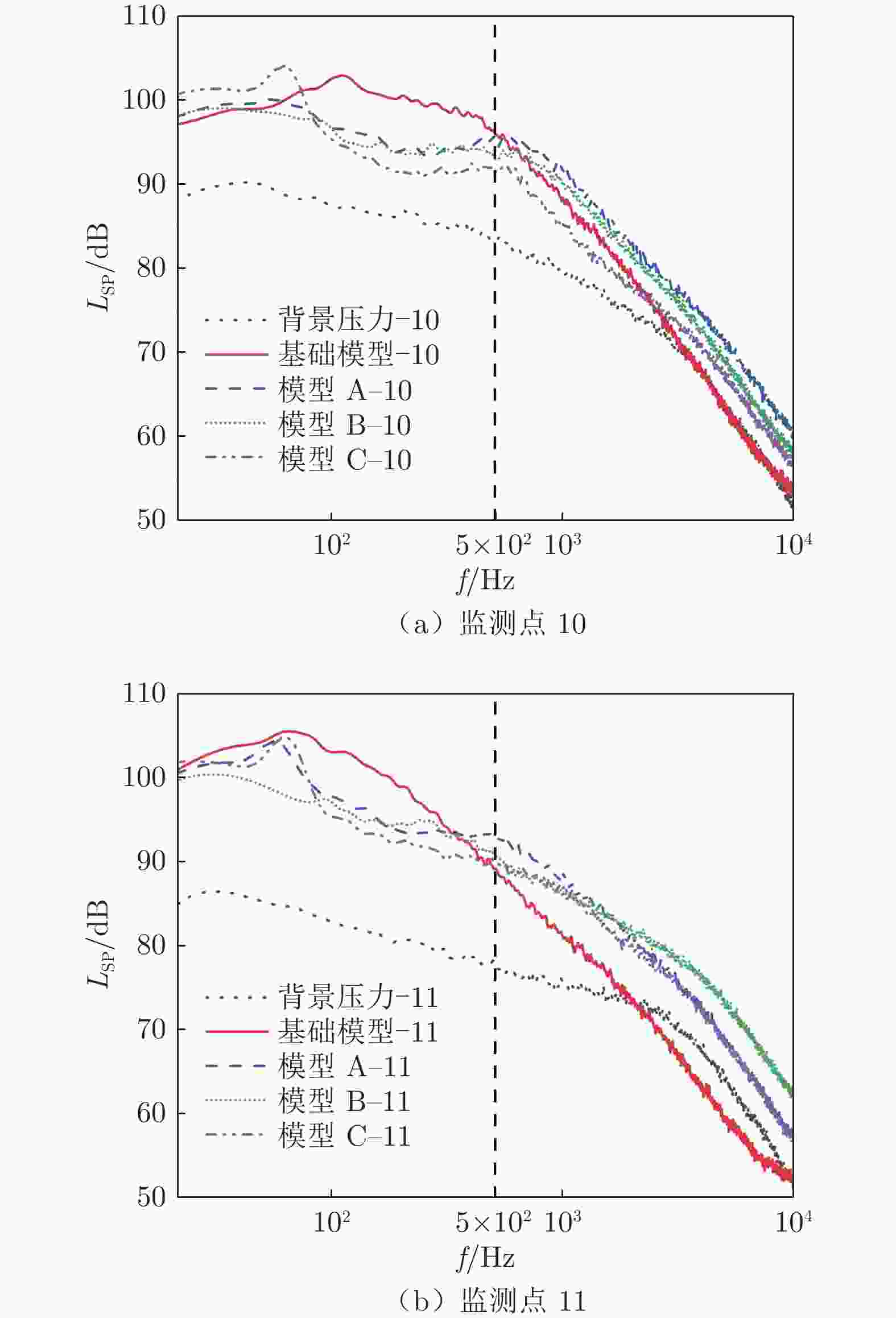

Table 2. Comparison table of overall sound pressure level of three monitoring points in the second row

单位:dB 监测点 10 11 12 背景压力 113.4 112.7 113.8 基础模型 126.7 125.0 126.9 模型 A 124.3 124.7 125.7 模型 B 122.8 123.5 124.1 模型 C 122.1 123.1 122.8 表 3 第三排3个监测点总声压级对照表

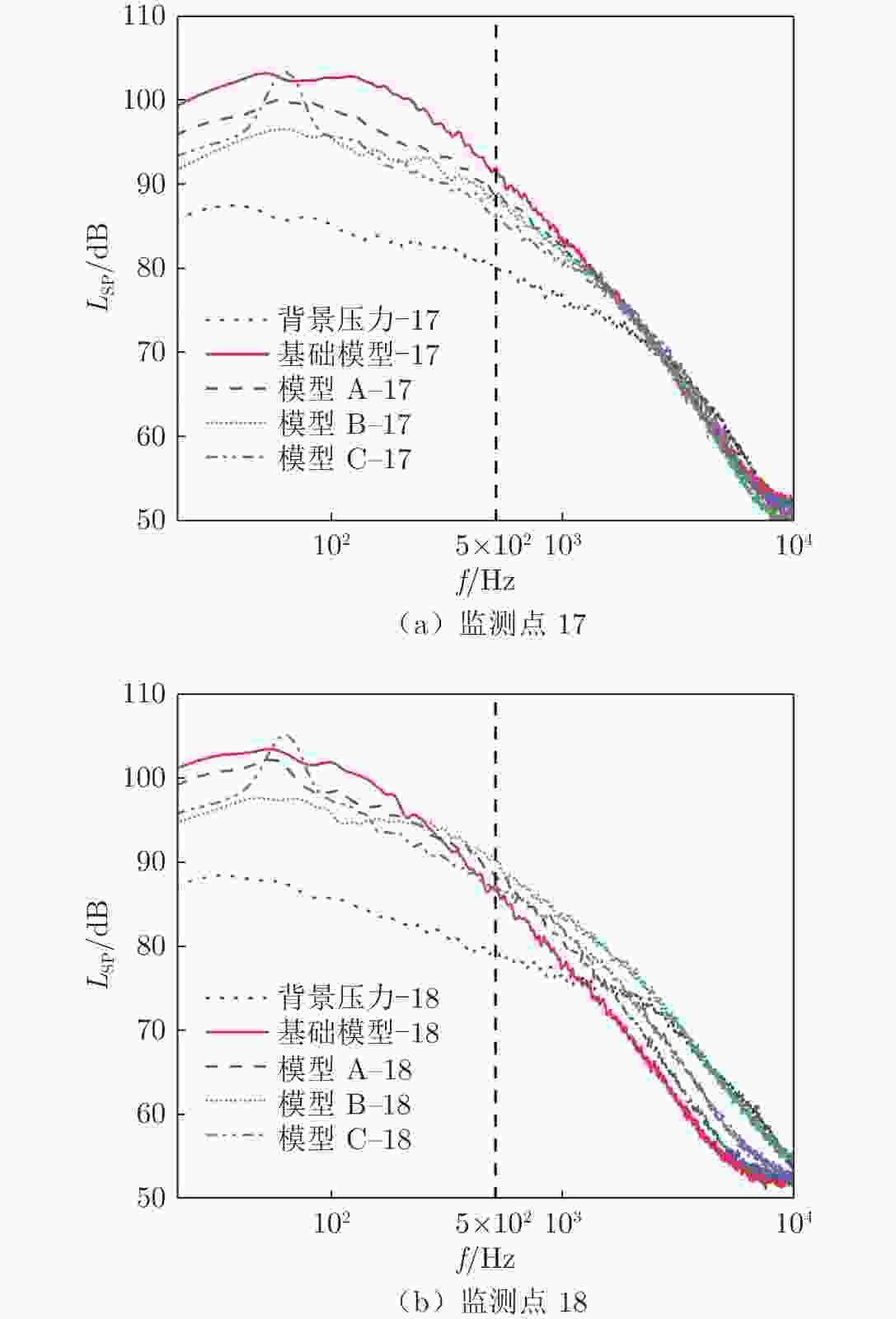

Table 3. Comparison table of overall sound pressure level of three monitoring points in the third row

单位:dB 监测点 17 18 19 背景压力 112.5 113.0 113.8 基础模型 126.5 124.4 126.3 模型 A 122.7 122.9 123.3 模型 B 120.5 122.1 121.3 模型 C 121.2 122.5 122.0 表 4 各改进模型与基础模型总声压级在不同频率范围内的差值

Table 4. Overall sound pressure level differences between the modified models and the generic simple model

单位:dB 20~500 Hz频段 20~104 Hz频段 ΔLsp1(模型 A−基础模型) −3.0 −1.9 ΔLsp2(模型 B−基础模型) −4.6 −3.3 ΔLsp3(模型 C−基础模型) −4.3 −3.7 表 5 模型阻力实验值

Table 5. Test values of models drag

单位:N 实验次数 基础模型 模型 A 模型 B 模型 C 1 4.229 3.733 3.489 3.911 2 4.257 3.739 3.478 3.930 3 4.262 3.768 3.476 3.953 4 4.277 3.760 3.479 3.965 5 4.287 3.784 3.480 3.983 均值 4.262 3.757 3.480 3.948 -

[1] BUCHHEIM R, DOBRZYNSKI W, MANKAU H, et al. Vehicle interior noise related to external aerodynamics[J]. International Journal of Vehicle Design, 1982, 3(4): 398–410. doi: 10.1504/IJVD.1982.061286 [2] HUCHO W, SOVRAN G. Aerodynamics of road vehicles[J]. Annual Review of Fluid Mechanics, 1993, 25: 485–537. doi: 10.1146/annurev.fl.25.010193.002413 [3] 沈钰贵, 陆森林, 孟新. 高速汽车侧窗气流噪声模拟[J]. 机械设计与制造, 2012(7): 125–127. doi: 10.3969/j.issn.1001-3997.2012.07.046SHEN Y G, LU S L, MENG X. Simulation on aerodynamic noise of automobile’s side window at high speed[J]. Machinery Design & Manufacture, 2012(7): 125–127. doi: 10.3969/j.issn.1001-3997.2012.07.046 [4] OETTLE N, MANKOWSKI O, SIMS-WILLIAMS D, et al. Evaluation of the aerodynamic and aeroacoustic response of a vehicle to transient flow conditions[J]. SAE International Journal of Passenger Cars - Mechanical Systems, 2013, 6(1): 389–402. doi: 10.4271/2013-01-1250 [5] GRAHS T, OTHMER C. Evaluation of aerodynamic noise generation: parameter study of a generic side mirror evaluating the aeroacoustic source strength[C]//European Conference on Computational Fluid Dynamics. 2006. [6] KIM D, KIM M, SAREDI E, et al. Robotic PTV study of the flow around automotive side-view mirror models[J]. Experimental Thermal and Fluid Science, 2020, 119: 110202. doi: 10.1016/j.expthermflusci.2020.110202 [7] KATO Y. Numerical simulations of aeroacoustic fields around automobile rear-view mirrors[J]. SAE International Journal of Passenger Cars - Mechanical Systems, 2012, 5(1): 567–579. doi: 10.4271/2012-01-0586 [8] LI Q L, YANG Z G, WANG Y G, et al. Experimental and numerical studies on aerodynamic noise of automotive rear view mirror[J]. Noise Control Engineering Journal, 2011, 59(6): 613. doi: 10.3397/1.3657481 [9] MOHAMUD O M, JOHNSON P. Broadband noise source models as aeroacoustic tools in designing low NVH HVAC ducts[C]//Proc of the SAE Technical Paper Series, 400 Commonwealth Drive. 2006. doi: 10.4271/2006-01-1192 [10] CHEN K H, JOHNSON J, DIETSCHI U, et al. Automotive mirror wind noise simulations and wind tunnel measurements[C]//Proc of the 14th AIAA/CEAS Aeroacoustics Conference (29th AIAA Aeroacoustics Conference). 2008. doi: 10.2514/6.2008-2906 [11] WALKER R, WEI W. Optimization of mirror angle for front window buffeting and wind noise using experimental methods[C]//Proc of the SAE Technical Paper Series Commonwealth Drive. 2007. doi: 10.4271/2007-01-2401 [12] YAO H D, DAVIDSON L, CHRONEER Z. Investigation of interior noise from generic side- View mirror using incompressible and compressible solvers of DES and LES[C]//Proc of the SAE Technical Paper Series, 400 Commonwealth Drive. 2018. doi: 10.4271/2018-01-0735 [13] 王雪钊. 后视镜优化对某轿车气动噪声的影响研究[D]. 镇江: 江苏大学, 2019.WANG X Z. Research on the influence of the wing mirror optimization on aerodynamic noise of A car[D]. Zhenjiang: Jiangsu University, 2019. [14] 刘红光, 陆森林. 高速车辆气流噪声计算方法[J]. 交通运输工程学报, 2002, 2(2): 41–44. doi: 10.3321/j.issn:1671-1637.2002.02.010LIU H G, LU S L. Calculation method of the aerodynamic noise around high speed vehicles[J]. Journal of Traffic and Transportation Engineering, 2002, 2(2): 41–44. doi: 10.3321/j.issn:1671-1637.2002.02.010 [15] 谢超, 谷正气, 杨振东, 等. 不同RANS/LES混合模型的汽车气动噪声分析[J]. 汽车工程, 2015, 37(4): 440–445, 459. doi: 10.3969/j.issn.1000-680X.2015.04.012XIE C, GU Z Q, YANG Z D, et al. Analysis on vehicle aerodynamic noise with different hybrid RANS/LES models[J]. Automotive Engineering, 2015, 37(4): 440–445, 459. doi: 10.3969/j.issn.1000-680X.2015.04.012 [16] 陈鑫, 冯晓, 沈传亮, 等. 车外后视镜造型对气动噪声影响的实验研究[J]. 汽车工程, 2017, 39(2): 206–213. doi: 10.19562/j.chinasae.qcgc.2017.02.014CHEN X, FENG X, SHEN C L, et al. An experimental study on the effects of exterior rearview mirrors styling on aerodynamic noise[J]. Automotive Engineering, 2017, 39(2): 206–213. doi: 10.19562/j.chinasae.qcgc.2017.02.014 [17] 陈鑫, 王宁, 沈传亮, 等. 后视镜造型对前侧窗气动噪声的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 426–436. doi: 10.13229/j.cnki.jdxbgxb20180867CHEN X, WANG N, SHEN C L, et al. Effect of rearview mirror modeling on aerodynamic noise of front window[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(2): 426–436. doi: 10.13229/j.cnki.jdxbgxb20180867 [18] 李启良, 杜文海, 王毅刚, 等. 基于主动射流的汽车后视镜区域气动噪声控制[J]. 同济大学学报(自然科学版), 2019, 47(8): 1195–1200. doi: 10.11908/j.issn.0253-374x.2019.08.017LI Q L, DU W H, WANG Y G, et al. Aerodynamic noise control of automobile rear view mirror based on active jet[J]. Journal of Tongji University (Natural Science), 2019, 47(8): 1195–1200. doi: 10.11908/j.issn.0253-374x.2019.08.017 [19] 姜豪, 赖万虎, 张思文, 等. 汽车后视镜气动噪声优化研究[J]. 汽车工程, 2020, 42(1): 121–126. doi: 10.19562/j.chinasae.qcgc.2020.01.018JIANG H, LAI W H, ZHANG S W, et al. Research on aeroacoustic optimization of vehicle rearview mirror[J]. Automotive Engineering, 2020, 42(1): 121–126. doi: 10.19562/j.chinasae.qcgc.2020.01.018 [20] LI Y Q, LIU Y Y, DING Z Y. Numerical simulation on the impact of the bionic structure on aerodynamic noises of sidewindow regions in vehicles[J]. Journal of Vibroengineering, 2018, 20(2): 1257–1271. doi: 10.21595/jve.2017.18779 [21] TAIRA K, BRUNTON S L, DAWSON S T M, et al. Modal analysis of fluid flows: an overview[J]. AIAA Journal, 2017, 55(12): 4013–4041. doi: 10.2514/1.J056060 -

下载:

下载: