Engineering approach of compressor test efficiency correction

-

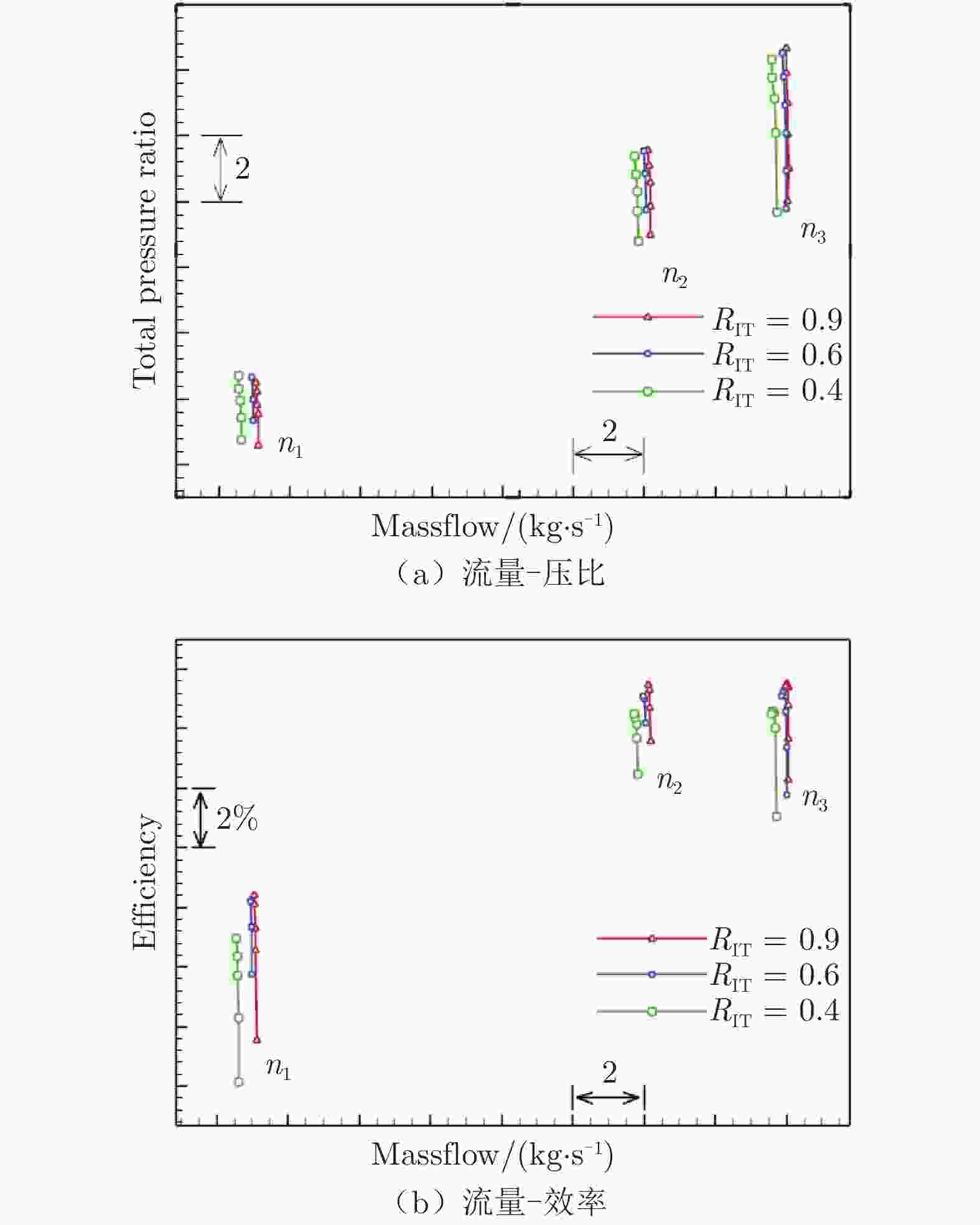

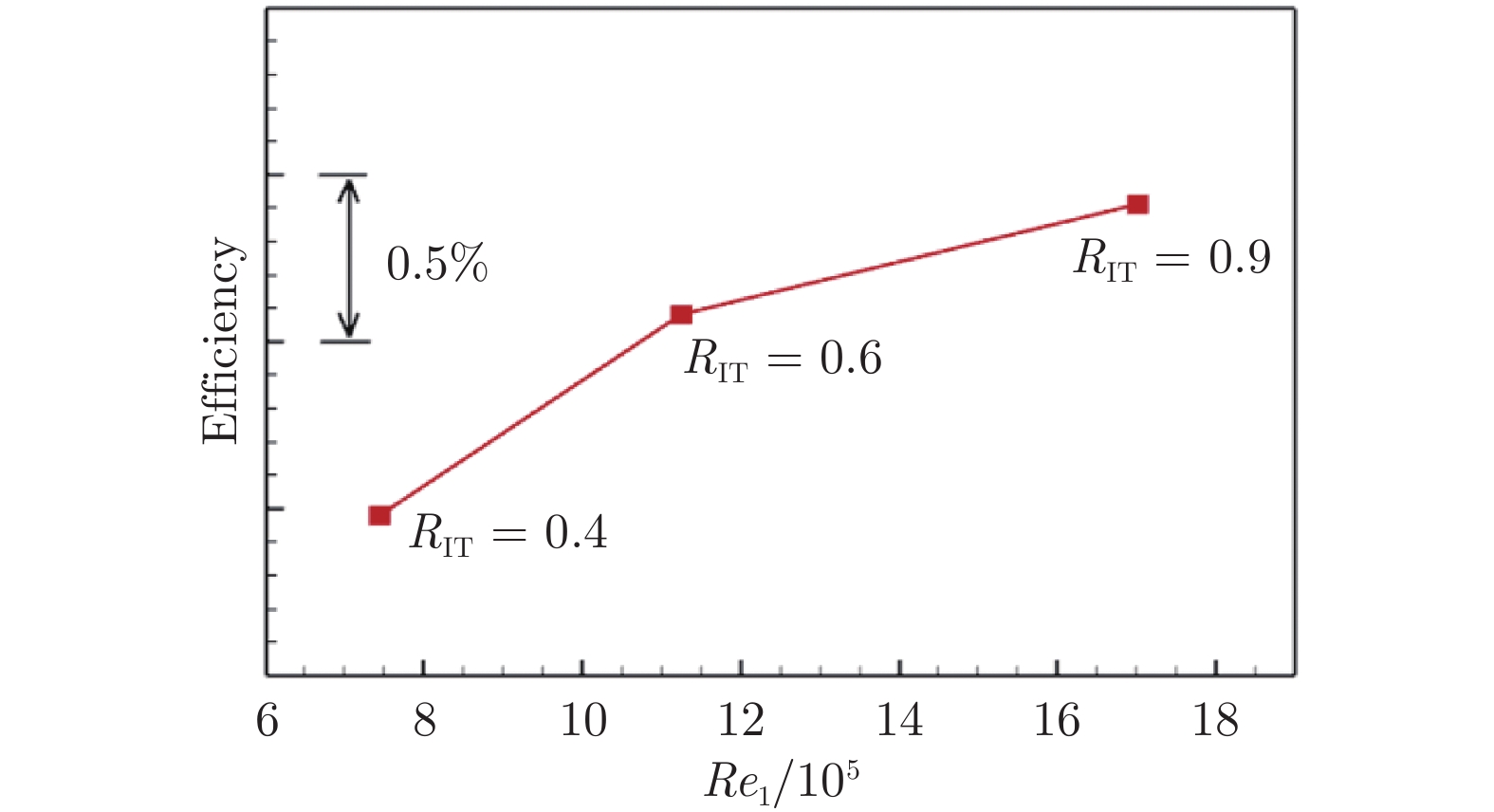

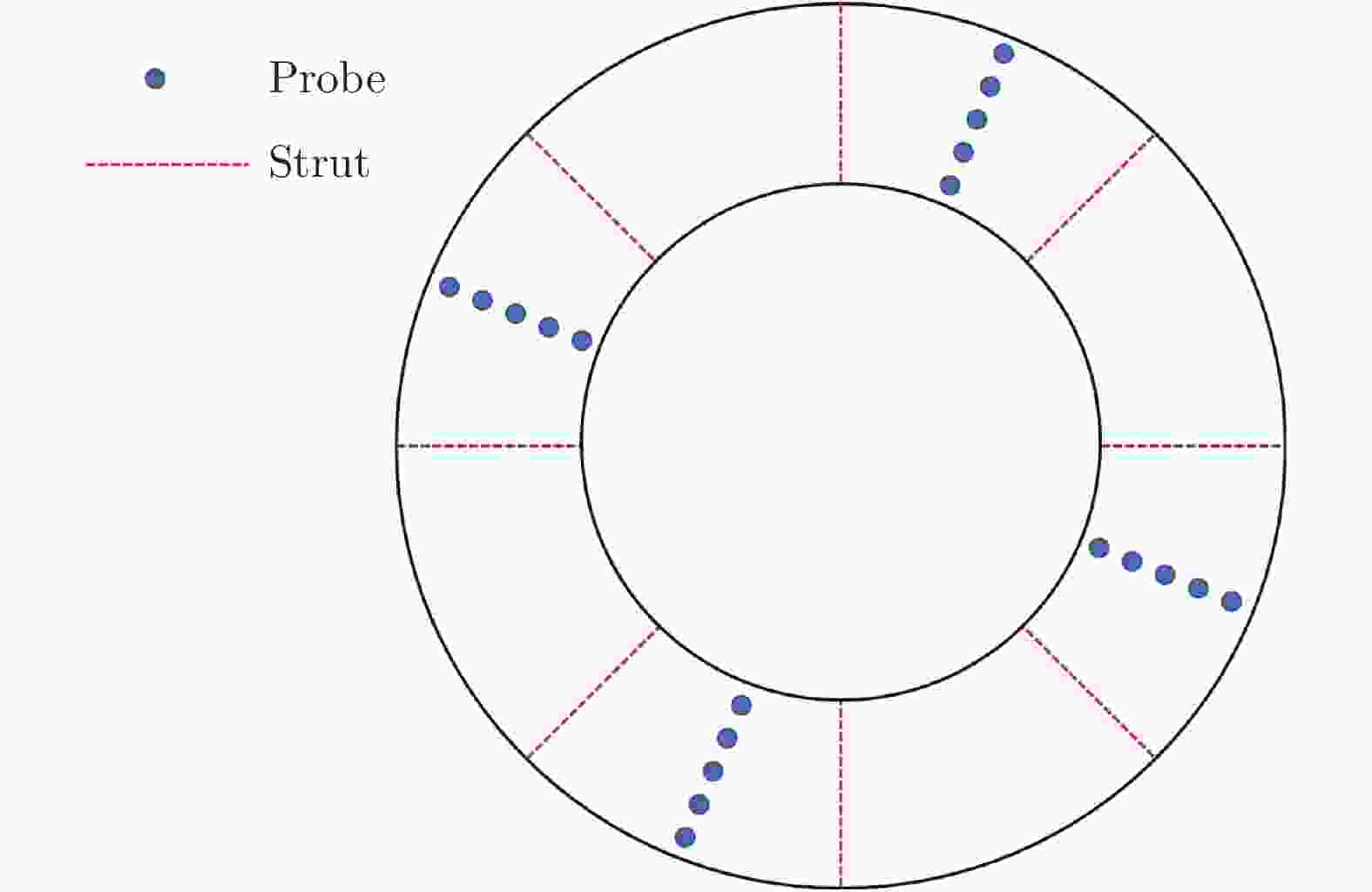

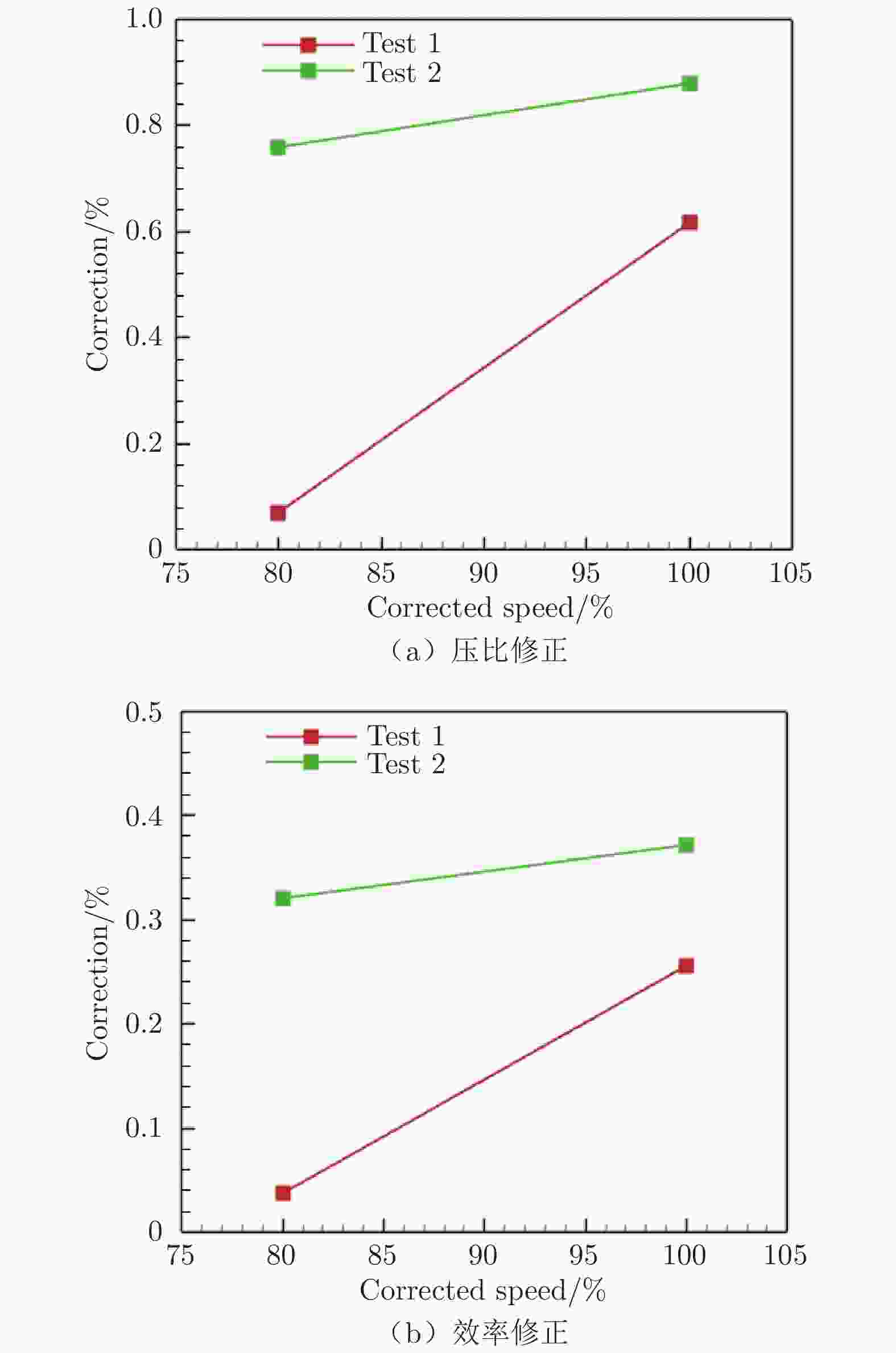

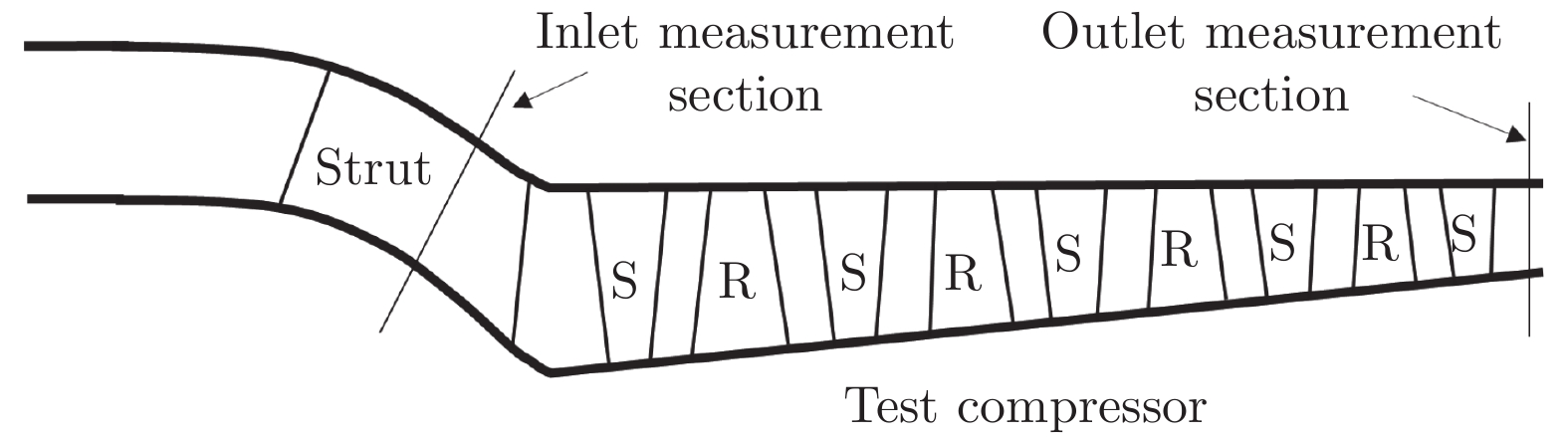

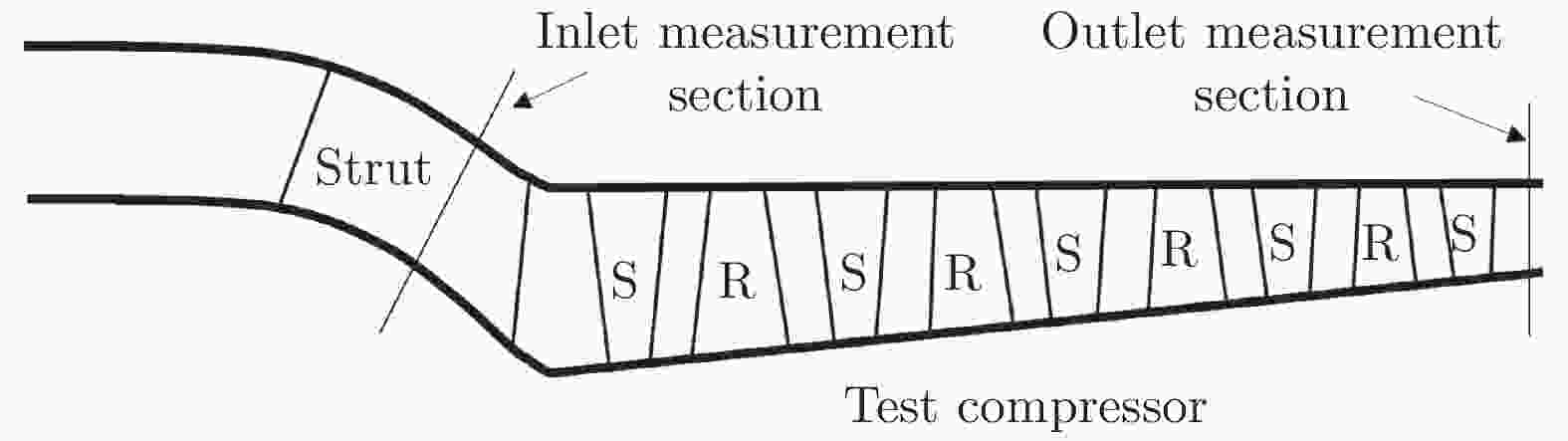

摘要: 效率是评价航空发动机压气机性能的重要指标,通常由试验直接获得。由于试验环境、结构构型和测点损失的影响,试验效率值需要修正后才能作为工程应用中性能评价和整机匹配的依据。本文提出了压气机试验效率的工程修正方法,对不同试验环境中压气机效率的影响因素进行系统分类,给出了雷诺数、进口过渡段损失、温度测量偏差、空气湿度和测试受感部损失等因素的具体修正方法。应用该方法对某10级压气机部件的试验效率进行修正,修正后效率提升了1.85%;对整机环境下压气机试验效率进行修正,修正后效率提升了0.95%。该方法可用于核心机/整机压气机试验效率修正和性能评定中。Abstract: Efficiency is the key parameter for evaluating compressor performance of the aero engine. It is usually acquired by compressor performance tests. Due to the difference in test condition, mechanical configuration, and instrumentation loss, efficiency obtained from compressor rig tests should be corrected for evaluating performance and engine matching in the engineering field. An engineering approach for correcting the compressor efficiency was proposed. The influence factors of the compressor efficiency were classified systematically under different test conditions, and detailed methods of correcting Reynolds number, inlet strut loss, thermo-couple Mach number recovery, air humidity and probe loss were given. Two examples were conducted using this method. The efficiency of a ten-stage compressor component rig test was corrected by 1.85 percent improvement. Besides, in the engine test, the compressor efficiency was corrected by 0.95 percent improvement. This method can be applied in the engineering field of efficiency measurement correction and performance evaluation for core and whole engines.

-

Key words:

- aero engine /

- compressor /

- efficiency test /

- engineering approach

-

表 1 测量参数最大允许误差

Table 1. Maximum error of measurement parameters

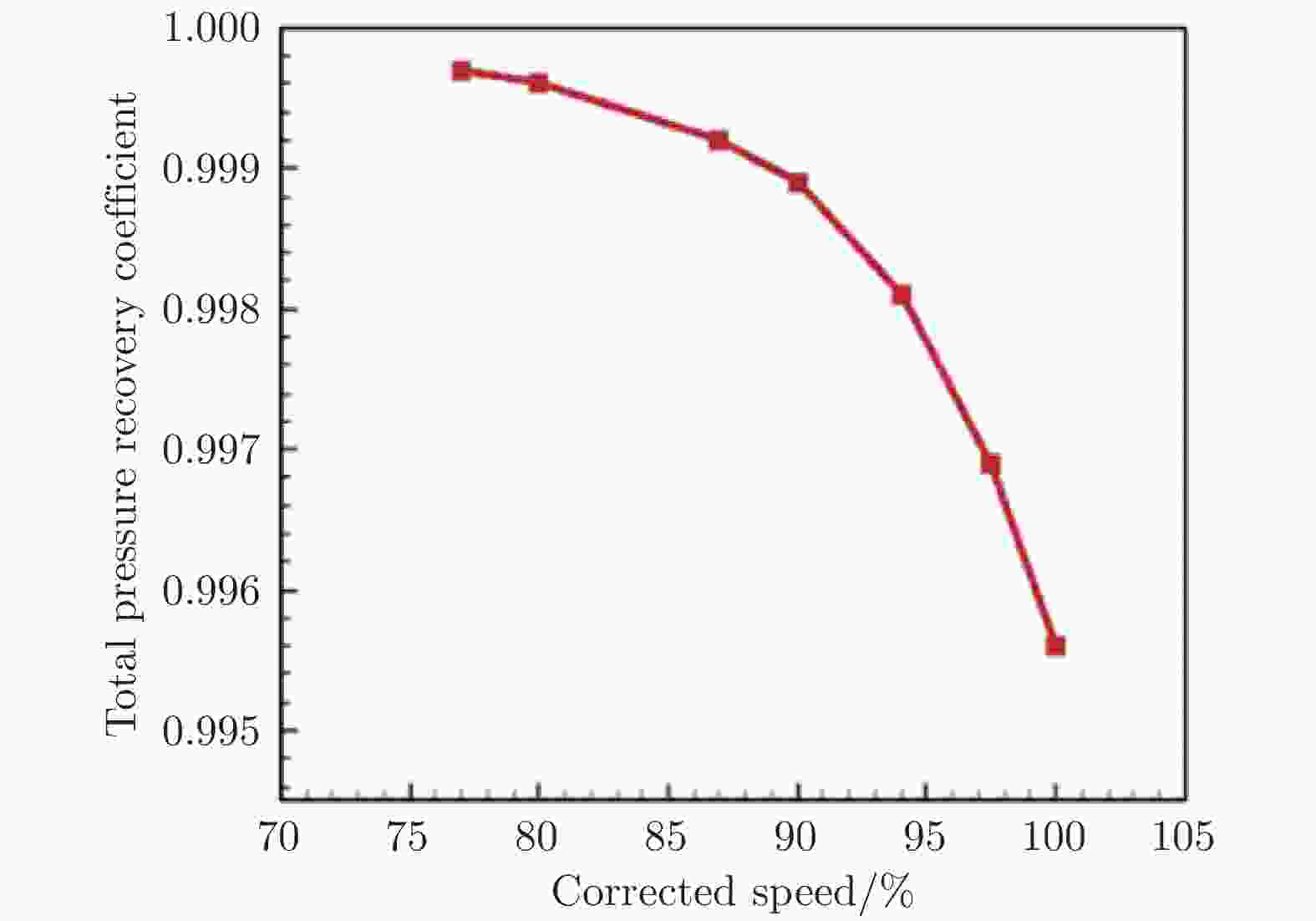

Parameters Maximum error ${T}_{ {{\rm{in}} } }^{*}$ ±1.0 K ${T}_{ {{\rm{ex}}} }^{*}$ ±2.0 K ${P}_{ {{\rm{in}}} }^{*}$ ±0.2% Pa ${P}_{ {{\rm{ex}}} }^{*}$ ±0.2% Pa 表 2 过渡段总压损失系数

Table 2. Total pressure recovery coefficient of intermediate casing

Corrected speed Total pressure recovery coefficient Test 1 Test 2 100%

(Work point)0.9938 0.9912 100%

(Near surge point)0.9939 0.9916 80%

(Work point)0.9993 0.9924 80%

(Near surge point)0.9994 0.9930 表 3 总温修正结果

Table 3. Result of total temperature correction

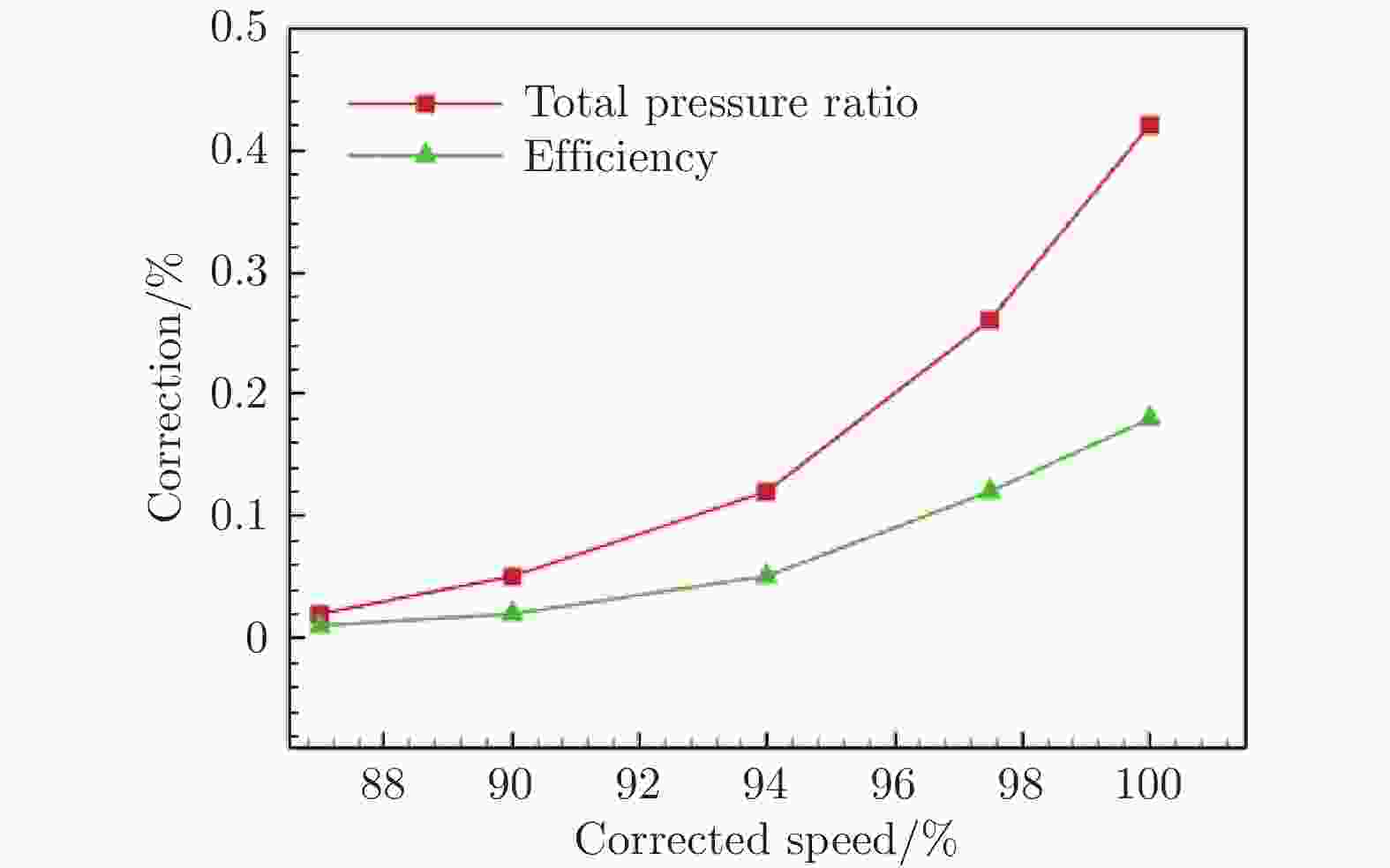

Parameters Value Inlet Mach number 0.45 Outlet Mach number 0.25 Correction of inlet total temperature 0.70 K Correction of outlet total temperature 0.59 K Correction of efficiency 0.21% 表 4 某10级压气机性能试验效率修正

Table 4. Correction of ten-stage compressor testing efficiency

Correction term Value Reynolds number 0.50% Strut loss 0.44% Temperature error 0.21% Air humidity −0.20% Probe loss 0.90% Total 1.85% 表 5 发动机整机试验压气机效率修正

Table 5. Correction of compressor efficiency in whole engine test

Correction term Value Strut loss 0.50% Temperature error 0.25% Air humidity −0.20% Probe loss 0.40% Total 0.95% -

[1] CUMPSTY N A. Compressor Aerodynamics[M] Malabar: Krieger Publishing Company, 2004. [2] BURMAN J, JOHANSSON T, LANGER P, et al. Design and performance of an efficient high specific power compressor[R]. ISABE 2009-1265, 2009. [3] KOFF B. Gas turbine technology evolution - A designer's perspective[C]//Proc of the AIAA International Air and Space Symposium and Exposition: The Next 100 Years. 2003. doi: 10.2514/6.2003-2722 [4] 桂幸民, 滕金芳, 刘宝杰. 航空压气机气动热力学理论与应用[M]. 上海: 上海交通大学出版社, 2014.GUI X M, TENG J F, LIU B J. Compressor aerothermodynamics and its applications in aircraftengines[M]. Shanghai: Shanghai Jiao Tong University Press, 2014. [5] 刘宝杰, 庄昕伟, 安广丰, 等. 轴流压气机低速试验效率测量分析[J]. 工程热物理学报, 2020, 41(10): 2425–2430.LIU B J, ZHUANG X W, AN G F, et al. Efficiency measurement analysis for low-speed axial compressor[J]. Journal of Engineering Thermophysics, 2020, 41(10): 2425–2430. [6] 任铭林, 向宏辉. 有关轴流压气机效率问题的探讨[J]. 燃气涡轮试验与研究, 2009, 22(4): 9–14. doi: 10.3969/j.issn.1672-2620.2009.04.002REN M L, XIANG H H. Exploration of efficiency in axial compressor[J]. Gas Turbine Experiment and Research, 2009, 22(4): 9–14. doi: 10.3969/j.issn.1672-2620.2009.04.002 [7] 崔济亚. 压气机效率的正确变比热计算[J]. 推进技术, 1995, 16(2): 1–3.CUI J Y. Correct calculation of varying specific heat compressor efficiency[J]. Journal of Propulsion Technology, 1995, 16(2): 1–3. [8] WALTHER R, FRISCHBIER J, SELMEIER R. Aeromechanical design of advanced engine compressors[R]. ISABE2001-1241, 2001. [9] BROICHHAUSEN K D, ZIEGLER K U. Supersonic and transonic compressors: past, status and technology trends[R]. ASME GT2005-69067, 2005. doi: 10.1115/GT2005-69067 [10] BRUN K, KURZ R. Measurement uncertainties encountered during gas turbine driven compressor field testing[J]. Journal of Engineering for Gas Turbines and Power, 2001, 123(1): 62–69. doi: 10.1115/1.1340628 [11] BETTOCCHI R, PINELLI M, SPINA P R. A multi-stage compressor test facility: uncertainty analysis and preliminary test results [R]. ASME GT2003-38397, 2003. doi: 10.1115/GT2003-38397 [12] WASSELL A B. Reynolds number effects in axial compressors[J]. Journal of Engineering for Gas Turbines and Power, 1968, 90(2): 149–156. [13] PELZ P F, STONJEK S S. The influence of Reynolds number and roughness on the efficiency of axial and centrifugal fans—A physically based scaling method[J]. Journal of Engineering for Gas Turbines and Power, 2013, 135(5): 052601–052609. doi: 10.1115/1.4022991 [14] 刘一彤, 宫武旗, 王琦, 等. 压气机级模化换算中雷诺数与粗糙度修正研究[J]. 工程热物理学报, 2021, 42(7): 1752–1759.LIU Y T, GONG W Q, WANG Q, et al. Study on Reynolds number and roughness correction in compressor stage geometric scaling[J]. Journal of Engineering Thermophysics, 2021, 42(7): 1752–1759. [15] JIN D H, LIU X W, ZHAO W G, et al. Optimization of endwall contouring in axial compressor S-shaped ducts[J]. Chinese Journal of Aeronautics, 2015, 28(4): 1076–1086. doi: 10.1016/j.cja.2015.06.011 [16] SHARMA M, BALONI B D. Design optimization of a compressor transition S-shaped duct using a teaching–learning-based optimization algorithm[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2019, 41(12): 1–18. doi: 10.1007/s40430-019-2072-5 [17] 李斌, 吴亚东, 滕金芳, 等. 压气机中介机匣几何结构的试验验证[J]. 航空动力学报, 2013, 28(10): 2326–2331.LI B, WU Y D, TENG J F, et al. Experimental validation of geometry of compressor intermediate casing[J]. Journal of Aerospace Power, 2013, 28(10): 2326–2331. [18] 辛亚楠, 李家军, 韩阳, 等. 大径向落差长度比中介机匣气动特性研究[J]. 推进技术, 2017, 38(4): 808–814.XIN Y N, LI J J, HAN Y, et al. Numerical study on aerodynamic characteristics of a large radius change to length ratio intermediate duct[J]. Journal of Propulsion Technology, 2017, 38(4): 808–814. [19] 吴思宇, 朱品武, 汪作心, 等. 过渡段部分对某高压压气机性能影响研究[J]. 热能动力工程, 2021, 36(9): 42–50.WU S Y, ZHU P W, WANG Z X, et al. Research on the effect of transition section on performance of high pressure compressor[J]. Journal of Engineering for Thermal Energy and Power, 2021, 36(9): 42–50. [20] DAY I, WILLIAMS J, FREEMAN C. Rain ingestion in axial flow compressors at part speed[J]. Journal of Turbomachinery, 2008, 130(1):011024-1-10-0 . doi: 10.1115/1.2366511 [21] NIKOLAIDIS T, PILIDIS P. The effect of water ingestion on an axial flow compressor performance[J]. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 2014, 228(3): 411–423. doi: 10.1177/0954410012474421 [22] BERDANIER R A, SMITH N R, FABIAN J C, et al. Humidity effects on experimental compressor performance—corrected conditions for real gases[J]. Journal of Turbomachinery, 2015, 137(3). doi: 10.1115/1.4028356 [23] 刘波, 曹志鹏, 高嵩, 等. 来流含水对航空发动机风扇/压气机特性的影响[J]. 航空动力学报, 2005, 20(6): 1041–1047. doi: 10.3969/j.issn.1000-8055.2005.06.025LIU B, CAO Z P, GAO S, et al. Influence of inlet water ingestion on aero-engine fan-compressor performance[J]. Journal of Aerospace Power, 2005, 20(6): 1041–1047. doi: 10.3969/j.issn.1000-8055.2005.06.025 [24] ZHENG Q, SUN Y F, LI S Y, et al. Thermodynamic analyses of wet compression process in the compressor of gas turbine [R]. ASME GT-2002-30590, 2009. [25] 杨璐, 郑群, 张海, 等. 轴流压气机吞水后的性能变化研究[J]. 推进技术, 2017, 38(7): 1499–1506.YANG L, ZHENG Q, ZHANG H, et al. Study on performance changes of axial flow compressor after water ingestion[J]. Journal of Propulsion Technology, 2017, 38(7): 1499–1506. [26] 安利平, 王掩刚, 朱自环, 等. 跨声速压气机湿压缩性能及流动特性研究[J]. 航空学报, 2022, 43: 126024.AN L P, WANG Y G, ZHU Z H, et al. Influence of wet compression on aerodynamic performance and stall boundary of transonic compressor[J]. Acta aeronautics et astronautica sinica, 2022, 43: 126024. [27] LOU F Y, FABIAN J, KEY N L. The effect of gas models on compressor efficiency including uncertainty[J]. Journal of Engineering for Gas Turbines and Power, 2014, 136(1): 012601–012609. doi: 10.1115/1.4025317 [28] 马宏伟, 项乐. 探针支杆对压气机转子性能及流场影响的数值模拟研究[J]. 推进技术, 2016, 37(12): 2288–2295.MA H W, XIANG L. Numerical investigation of effects of probe support on performance and flow field of compressor rotor[J]. Journal of Propulsion Technology, 2016, 37(12): 2288–2295. [29] MA H W, JIN C, ZHAO L P, et al. Effects of airfoil-probe tubes on the flow field of a compressor cascade[J]. Journal of Thermal Science, 2017, 26(4): 321–330. doi: 10.1007/s11630-017-0945-4 [30] 杨荣菲, 赵建通, 向宏辉, 等. 进口探针支杆对1.5级压气机气动性能的影响[J]. 推进技术, 2017, 38(5): 1038–1046.YANG R F, ZHAO J T, XIANG H H, et al. Effects of inlet probe support on aerodynamic performance of 1.5-stage compressor[J]. Journal of Propulsion Technology, 2017, 38(5): 1038–1046. [31] 《航空发动机设计手册》总编委会. 航空发动机设计手册(第8分册): 压气机[M]. 北京: 航空工业出版社, 2006. [32] 陈云永, 马昌友, 孙震宇, 等. 引气对高压压气机效率评价影响分析[J]. 实验流体力学, 2021, 35(2): 43–49. doi: 10.11729/syltlx20200097CHEN Y Y, MA C Y, SUN Z Y, et al. Effect of bleed on efficiency evaluation of high pressure compressor[J]. Journal of Experiments in Fluid Mechanics, 2021, 35(2): 43–49. doi: 10.11729/syltlx20200097 [33] 赵俭, 杨永军. 气流温度测量技术[M]. 北京: 中国质检出版社, 2017. [34] 童钧耕. 工程热力学[M]. 4版. 北京: 高等教育出版社, 2007. [35] 《高效节能发动机文集》编委会. 高效节能发动机文集 第3分册: 风扇、压气机设计与试验[M]. 北京: 航空工业出版社, 1991. -

下载:

下载: