A preliminary study of segmented arc heater used for high pressure operation

-

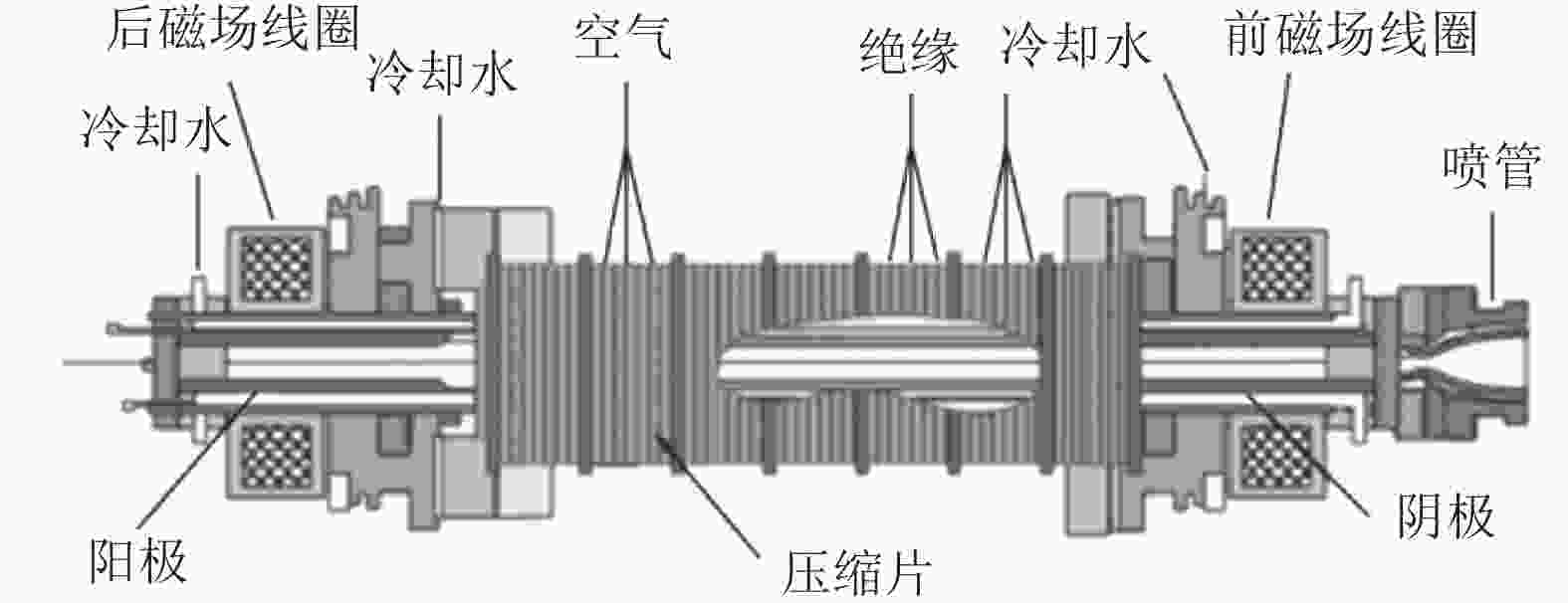

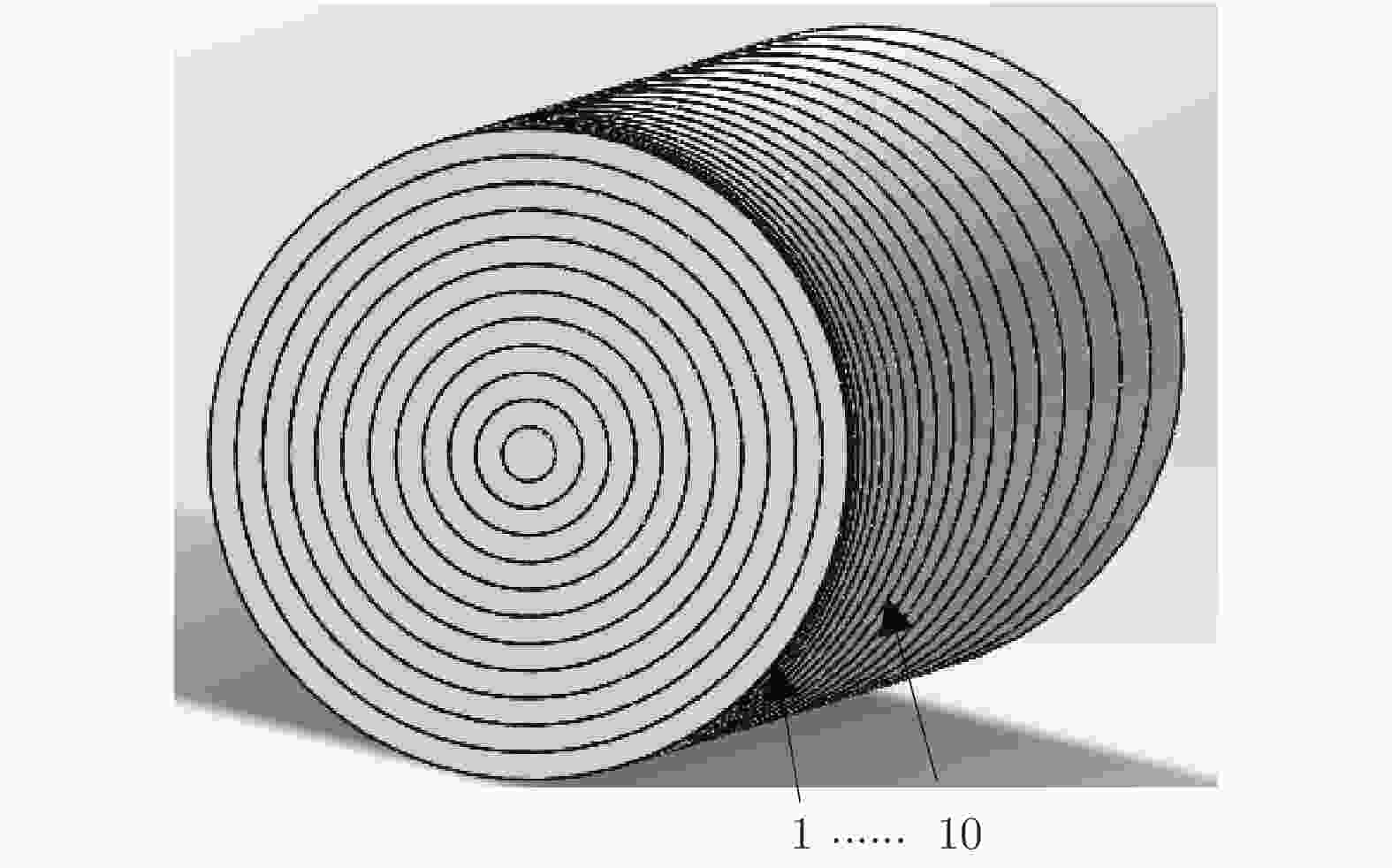

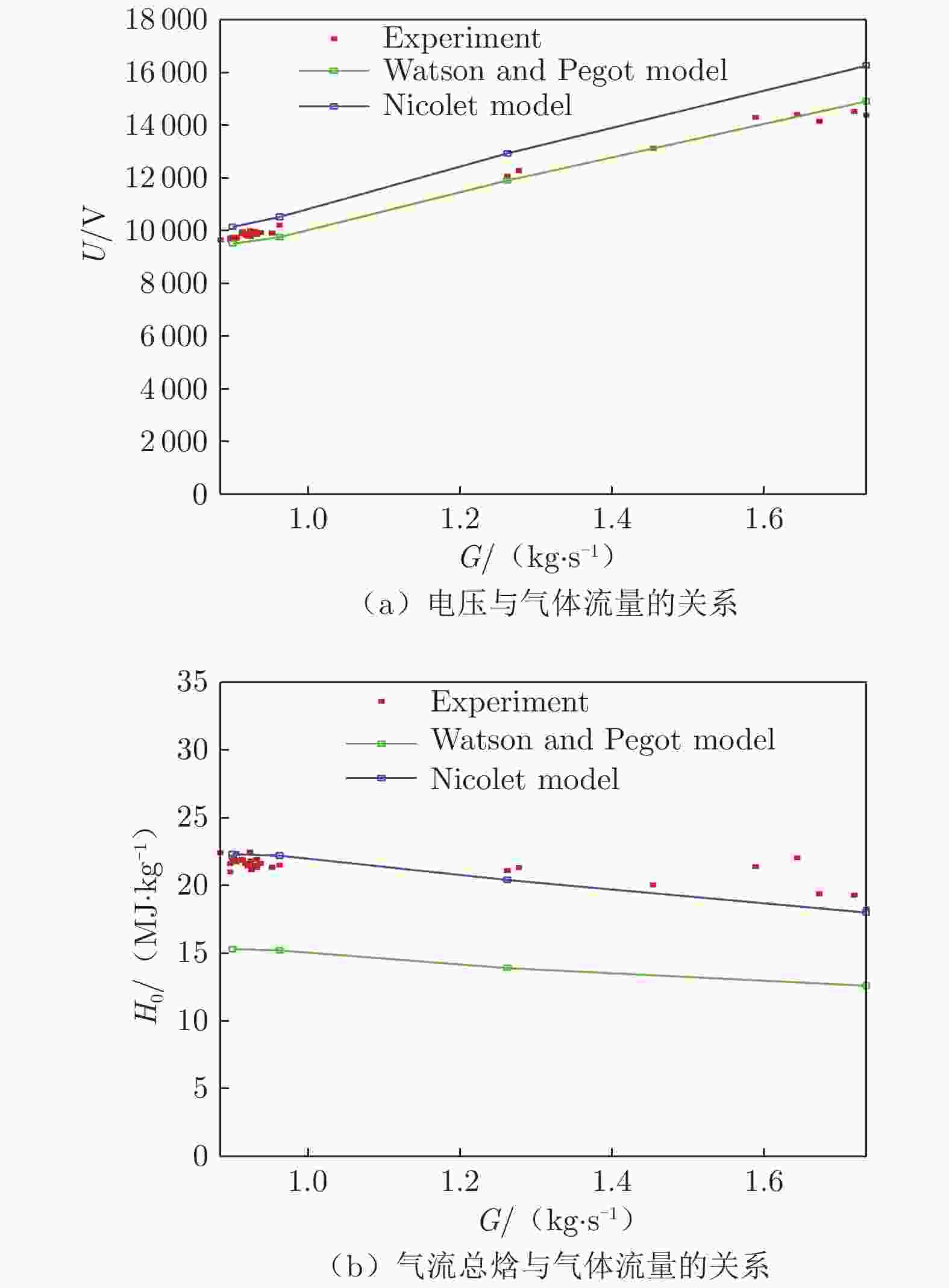

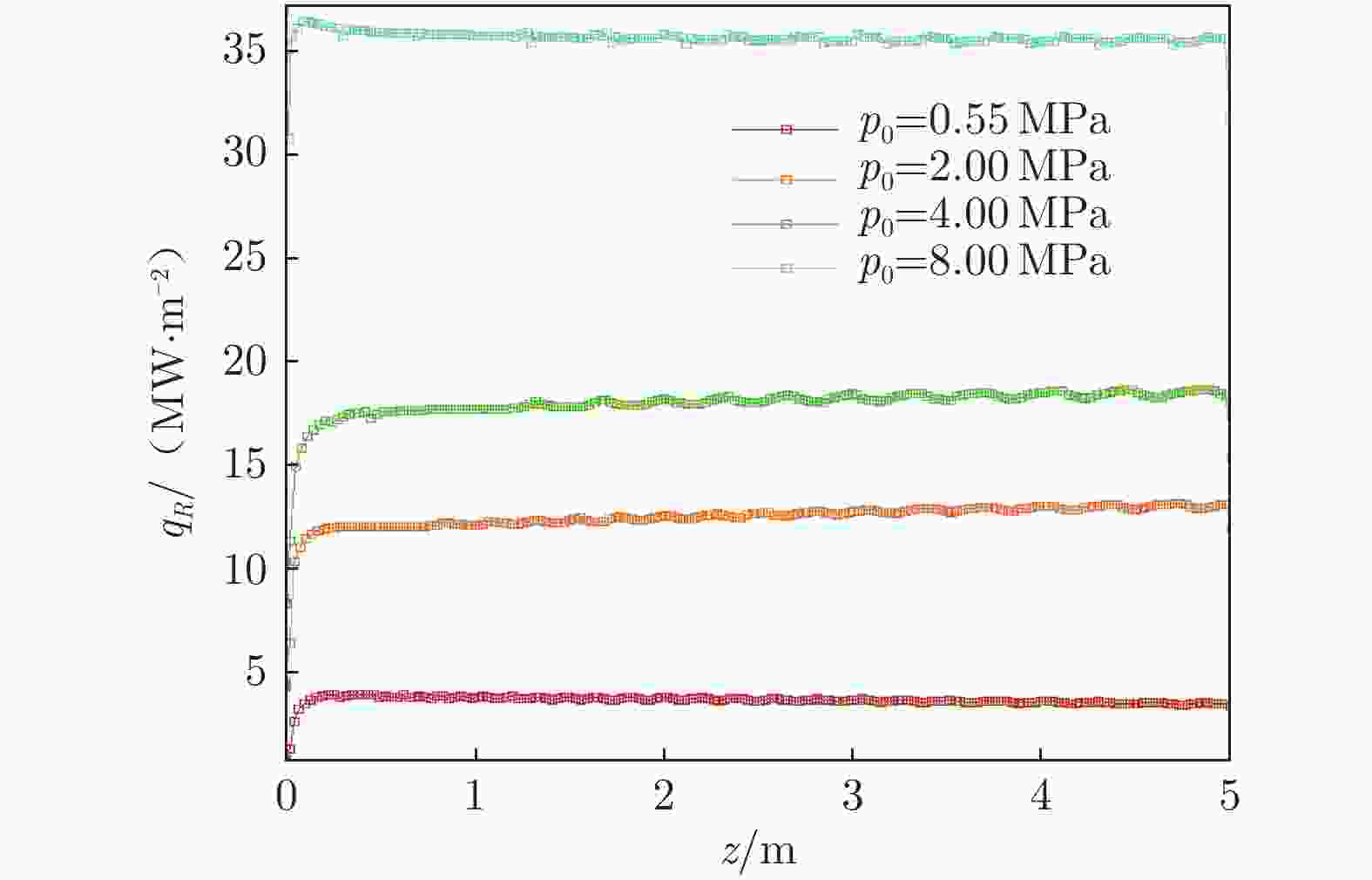

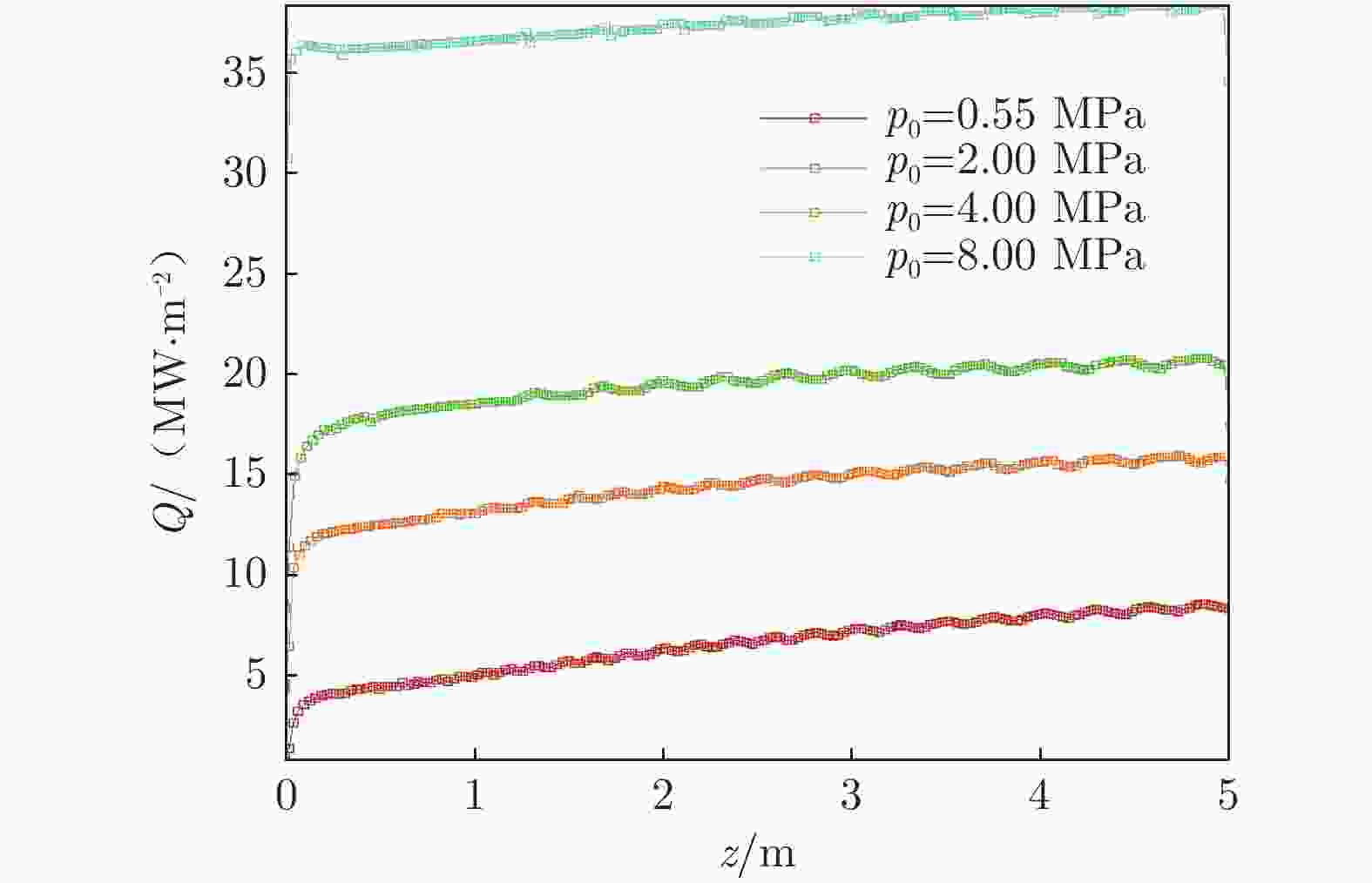

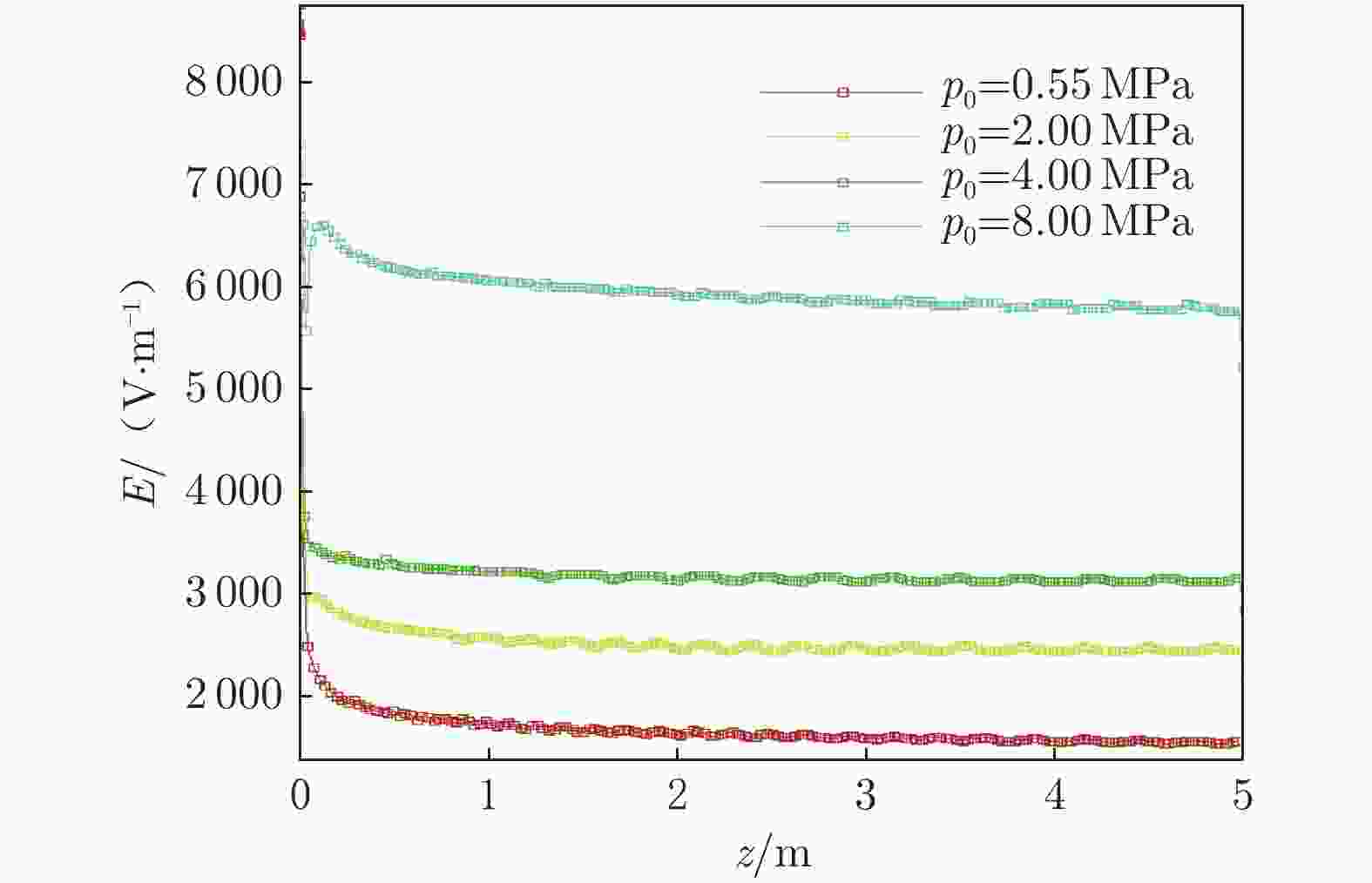

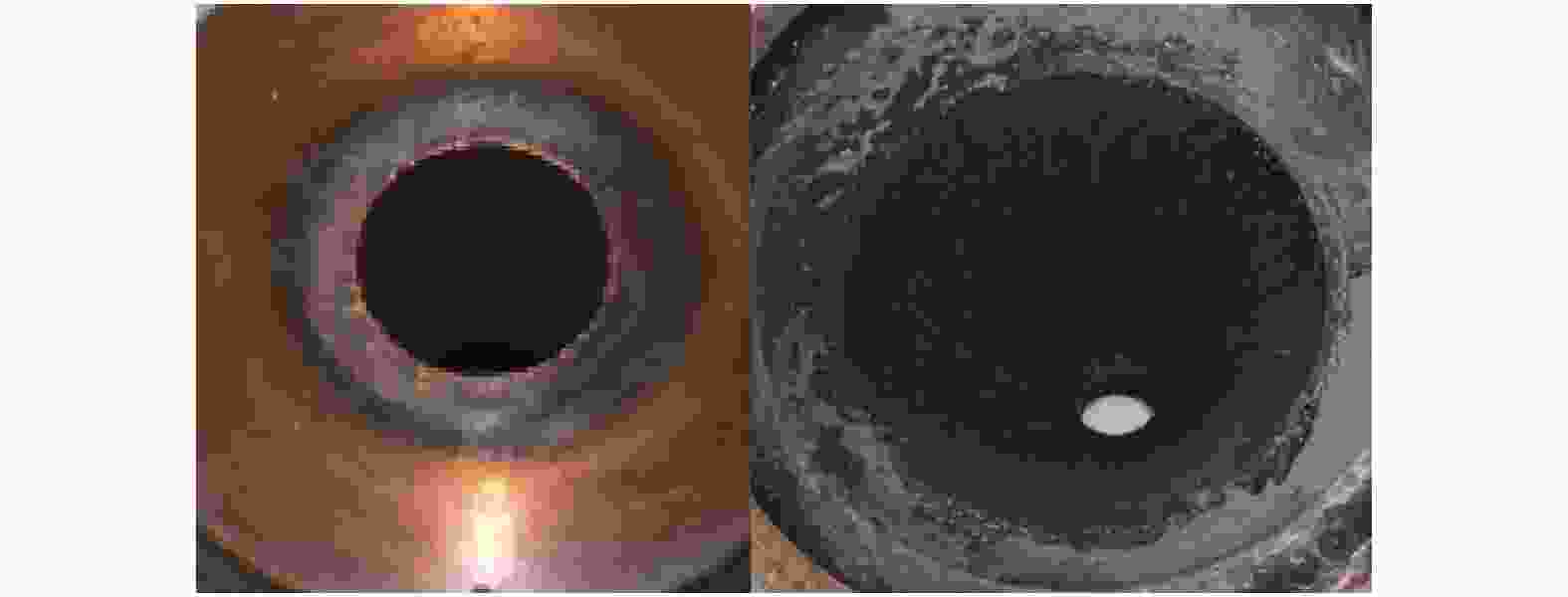

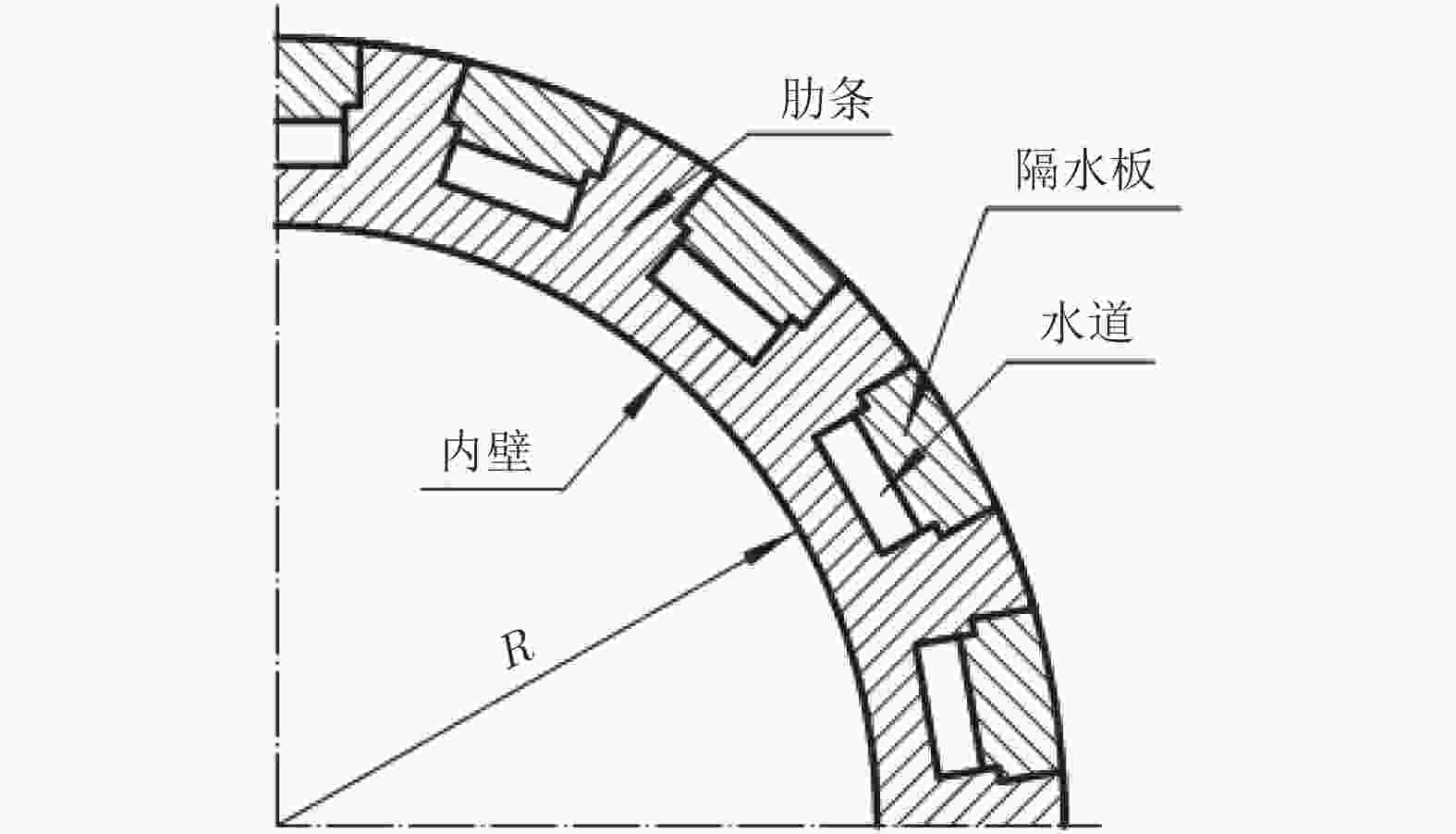

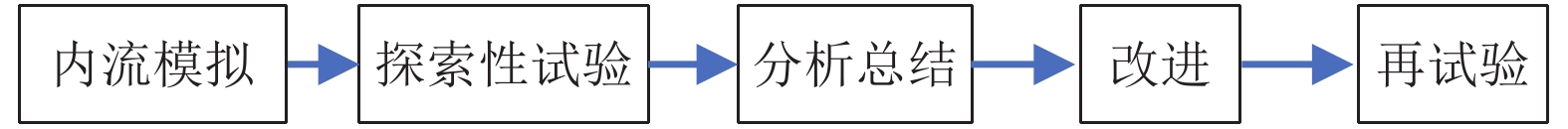

摘要: 片式电弧加热器模拟焓值范围宽,是开展热防护试验的理想设备。为拓宽其压力模拟范围,开展了片式电弧加热器内流分析方法研究,并与片式电弧加热器高气压试验进行了对比,结果吻合较好。为解决高气压运行试验出现的问题,研制了耐压、耐高热流压缩片,增强了压缩片的冷却效果,短化了片式电弧加热器电极,采取内壁防护措施使表面高温氧化产物减少和热量损失降低。探索高气压片式电弧加热器运行模式,解决了高气压运行串弧问题。试验的运行压力超过10 MPa,单电极运行电弧电流超过5000 A,提高了片式电弧加热器的试验能力。Abstract: The segmented arc heater is an ideal thermal protection test equipment for having a wide range of enthalpy. In order to broaden the simulation range of pressure, the analysis method of the segmented arc heater internal flow is developed. The prediction results match the high pressure operation test results. To solve the problems in the high pressure test, some technical measures have been taken the pressure and heat resistance segments are developed cooling is strengthen and the electrode is shortened. The internal protective measures are studied to reduce surface oxidation and heat loss of segments. The operational mode is explored to solve the string arc problem in the high pressure operation test. The operation pressure of the test exceeds 10 MPa, the operation current exceeds 5000 A on a single electrode, which improves the testing ability of the segmented arc heater.

-

Key words:

- segmented arc heater /

- high pressure /

- electrode

-

表 1 国外大功率片式电弧加热设备的参数

Table 1. Parameter of foreign high-power segmented arc heater

设备 Pmax/MW H0/(MJ·kg−1) p0/MPa Ames IHF 42 7.0~46.4 0.10~1.01 Scirocco PWT 70 2.5~45.0 0.10~1.67 AEDC H3 68 1.4~19.8 0.10~19.60 表 2 典型车次的参数表

Table 2. Operation parameters of the arc heater

车次 I/A G/(kg·s−1) p0/MPa 1 1400 0.7 10.20 2 2500 2.4 7.60 3 2800 4.1 6.40 4 3000 4.5 1.80 5 3000 3.8 3.90 6 5200 1.8 1.20 -

[1] HOCHREIN G, G WRIGHT J Jr. Analysis of the TATER nosetip boundary layer transition and ablation experiment[C]//Proc of the 14th Aerospace Sciences Meeting. 1976. doi: 10.2514/6.1976-167 [2] 陈连忠, 欧东斌, 高贺, 等. 高超声速飞行器热防护电弧风洞气动加热试验技术[M]. 北京: 科学出版社, 2020: 27-48.CHEN L Z, OU D B, GAO H, et al. Aerodynamic heating test technology of thermal protection arc wind tunnel for hypersonic vehicle[M]. Beijing: Science Press, 2020: 27-48. [3] BALTER-PETERSON A, NICHOLS F, MIFSUD B, et al. Arc jet testing in NASA Ames Research Center thermo-physics facilities[C]//Proc of the AlAA 4th International Aerospace Planes Conference. 1992. doi: 10.2514/6.1992-5041 [4] VOTTA R,MARINI M,FILIPPIS F D,et al. Design and feasibility of ExoMars supersonic parachute scirocco test[J]. Journal of Spacecraft and Rockets,2010,47(6):981-993. doi: 10.2514/1.50230 [5] FILIPPIS F D, VECCHIO A, CARISTIA S. Scirocco plasma wind tunnel: low enthalpy by use of cold air transverse injection[R]. AIAA 2003-6959, 2003. [6] PURPURA C. CIRA PWT user manual[R]. CIRA-UM-04-008, 2003. [7] HORN D D, SMITH B T. Result of testing the AEDC 5-MW segmented arc heater at pressures up to 171 atm[R]. AD-A017 288, 1975. [8] SMITH D M, YOUNKER T. Comparative ablation testing of carbon phenolic TPS materials in the AEDC-H1 arcjet[C]//Proc of the AIAA/CIRA 13th International Space Planes and Hypersonics Systems and Technologies Con- ference. 2005. doi: 10.2514/6.2005-3263 [9] SHEELEY J, WHITTINGHAM K, MONTGOMERY P, et al. Extending arc heater operating pressure range for improved reentry simulation[C]//Proc of the 25th AIAA Aerodynamic Measurement Technology and Ground Testing Conference. 2006. doi: 10.2514/6.2006-3295 [10] Arnold Air Force Base. AEDC 2008 Annual Report[R]. 2009. [11] 陈连忠,张友华. 电弧加热设备的类型及趋势[J]. 宇航材料工艺,2011(2):34-42. doi: 10.3969/j.issn.1007-2330.2011.02.010CHEN L Z,ZHANG Y H. Types and trend of arc heater facility[J]. Aerospace Materials & Technology,2011(2):34-42. doi: 10.3969/j.issn.1007-2330.2011.02.010 [12] DUBREUS T, SHEELEY J, STEWART J. Development of a mid-pressure arc-heated facility for hypersonic vehicle testing[C]//Proc of the U. S. Air Force T&E Days 2010. 2010. doi: 10.2514/6.2010-1732 [13] 国义军, 石卫波, 曾磊, 等. 高超声速飞行器烧蚀防热理论与应用[M]. 北京: 科学出版社, 2019: 433-443.GUO Y J, SHI W B, ZENG L, et al. Mechanism of ablative thermal protection applied to hypersonic vehicles[M]. Beijing: Science Press, 2019: 433-443. [14] 杨远剑,陈德江,赵文峰,等. 电弧风洞转动部件动密封试验[J]. 空气动力学学报,2017,35(6):828-831. doi: 10.7638/kqdlxxb-2015.0147YANG Y J,CHEN D J,ZHAO W F,et al. Seal comple-mentation test for rotatable parts in arc heated wind tunnel[J]. Acta Aerodynamica Sinica,2017,35(6):828-831. doi: 10.7638/kqdlxxb-2015.0147 [15] 杨鸿,罗跃,吴东,等. 电弧加热器超声速湍流平板烧蚀流场变化研究[J]. 实验流体力学,2018,32(4):72-77. doi: 10.11729/syltlx20170181YANG H,LUO Y,WU D,et al. Study on supersonic turbulence plate ablation flow field in arc heater[J]. Journal of Experiments in Fluid Mechanics,2018,32(4):72-77. doi: 10.11729/syltlx20170181 [16] 姚峰,朱超,陈德江,等. 直流电弧加热器多电极运行技术试验研究[J]. 实验流体力学,2014,28(3):82-86. doi: 10.11729/syltlx20130048YAO F,ZHU C,CHEN D J,et al. Experimental research of arc heater with multiple electrodes[J]. Journal of Experi-ments in Fluid Mechanics,2014,28(3):82-86. doi: 10.11729/syltlx20130048 [17] LIN X,OU D B,PENG J L,et al. Cooling-water leakage diagnosis using optical emission spectroscopy for a large-scale arc-heated facility[J]. Journal of Thermophysics and Heat Transfer,2019,33(4):900-906. doi: 10.2514/1.T5651 [18] PEGOT E B, WATSON V. Numerical calculations for the characteristics of a gas flowing axially through a constricted arc[R]. NASA TN D-4042, 1967. [19] NICOLET W, SHEPARD C, CLARK K, et al. Analytical and design study for a high-pressure, high-enthalpy constricted arc heater[R]. AEDC-TR-75-47, 1975. [20] LEE J I,KIM C,KIM K H. Accurate computations of arc-heater flows using two-equation turbulence models[J]. Journal of Thermophysics and Heat Transfer,2007,21(1):67-76. doi: 10.2514/1.25495 [21] KIM K H. Numerical investigation of plasma flows inside segmented constrictor type arc-heater[M]//Aeronautics and Astronautics. London: IntechOpen, 2011. doi: 10.5772/18769 [22] 刘初平,隆永胜,白菡尘,等. 超燃冲压发动机电弧加热器试验流场调试[J]. 实验流体力学,2005,19(4):42-45. doi: 10.3969/j.issn.1672-9897.2005.04.008LIU C P,LONG Y S,BAI H C,et al. A preliminary study of the arc flow field for scramjet research[J]. Journal of Experiments in Fluid Mechanics,2005,19(4):42-45. doi: 10.3969/j.issn.1672-9897.2005.04.008 -

下载:

下载: