Experimental research on the mixture properties inside cloud cavitation region

-

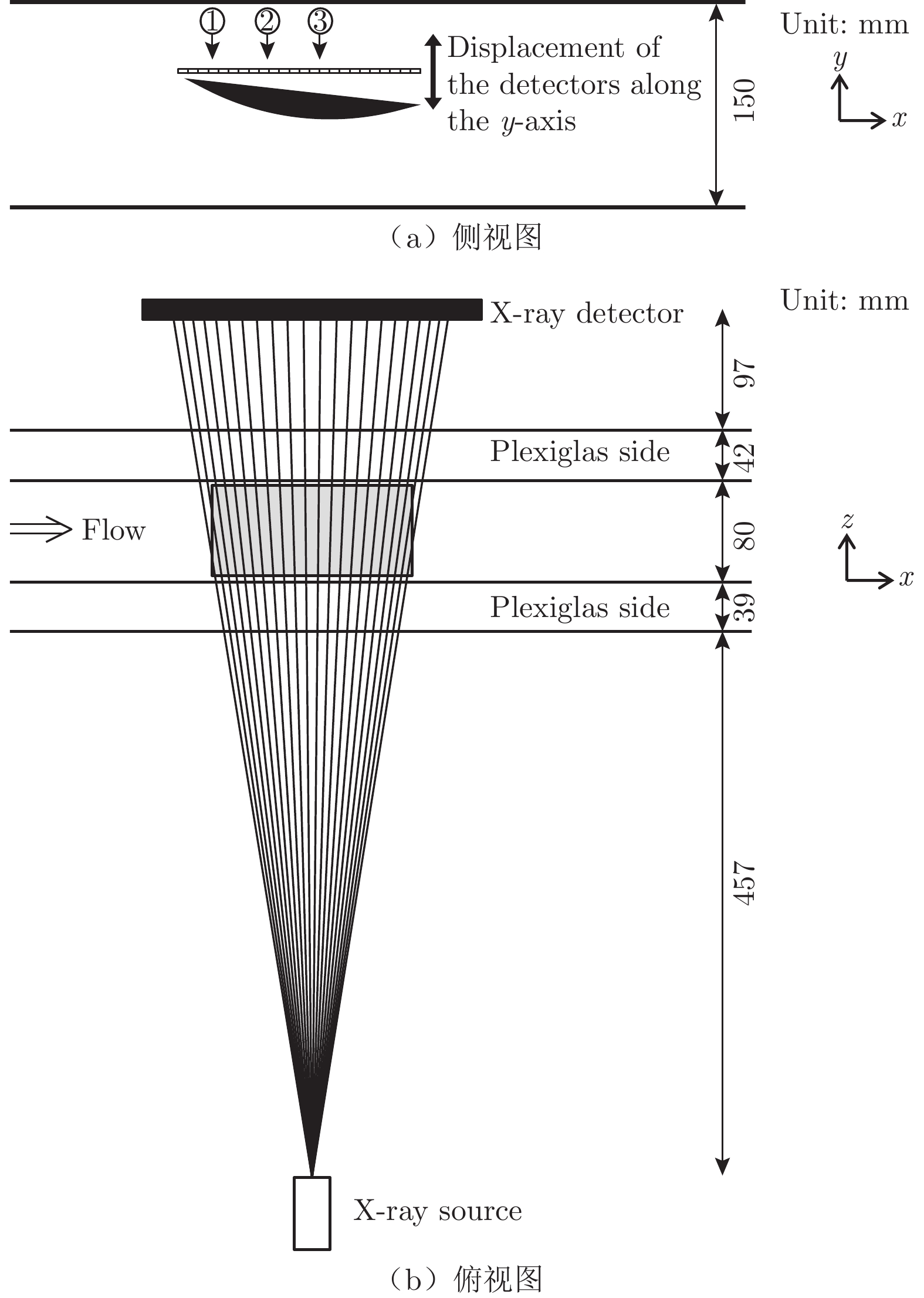

摘要: 空化流动是水动力学领域一种特有的流动现象,空化区内部水汽掺混情况复杂,需要借助特殊实验测量手段来获取其中混合介质特性。本文回顾了用于空化区多相混合介质测量的非接触式和接触式实验方法,包括电离辐射、内窥技术、电阻探针和光纤探针等。相比于对实验条件要求较高的非接触式测量技术,接触式探针测量技术更加简便和稳定,可以得到单个测点位置的含汽率、汽泡速度和汽泡尺度等信息。此外,本文还介绍了近年来多相流探针技术在空化流测量中的应用。研究者们分别采用电阻探针和光纤探针,研究了空泡水筒中楔形平板空化和水翼空化内部的介质特性,得到的结果主要包括平均含汽率和汽泡尺度统计分布两方面,发现了云空化区内含汽率高低与空化数密切相关,且楔形平板空化流动和水翼空化流动中存在非常相似的汽泡尺度分布特征。Abstract: Cavitating flows are unique phenomena in the research field of hydrodynamics. Within the cavitation region, vapor and water are mixed in a complex state. Special experimental techniques are required to obtain the mixture properties. Both non-intrusive and intrusive techniques for cavitating mixture measurement are reviewed, including ionizing radiation, endoscopy, electrical impedance probes and optical fiber probes. In comparison with the experimentally demanding non-intrusive methods, intrusive probe techniques provide simple and stable single-point measurements for the void fraction, bubble velocity and bubble size. Recent applications of phase-resolved probe techniques are then introduced. The electrical impedance probe and optical fiber probe were used in the mixture property measurements in wedge-plate and hydrofoil cavitation, respectively. The time-averaged void fraction and statistical distribution of the bubble size were obtained. The results indicate that the void fraction within cloud cavitation is closely related to the cavitation number, and the characteristics of the bubble size distribution are quite similar between the two kinds of cloud-cavitating flows (wedge-plate and hydrofoil cavitation).

-

Key words:

- cavitation /

- two-phase flows /

- void fraction /

- bubble size distribution

-

表 1 空化内部介质测量技术的主要特性

Table 1. Main characteristics of different techniques for cavitation mixture measurement

技术名称 基本原理 可测量物理量 主要优点 主要缺点 X射线 由于波长远小于可见光,因此可以穿透遮蔽光路的介质,通过显示不同相之间的边界,实现多相流的阴影成像 空泡内部的平均含汽率分布和速度场 可观测空泡内部相界面的运动,时间分辨率较高;对流场无扰动 测量结果为沿展向的投影,无法辨识沿展向不规则的空泡结构;实验装置复杂,辐射防护要求较高 内窥镜 采用局部光源照明,将流场内部图像转化为数字化光纤信号,通过光纤传送到信号接收装置,实现图像存储、显示 局部视域内的汽泡图像(可通过附加PIV测速系统得到微汽泡尾迹流场) 可近距离、直观地获得空泡内部微汽泡的形态;通常安装在壁面边界上,不会影响流场 仅可实现两相流空间拓扑结构的定性观测,无法定量估算含汽率、汽泡尺度等信息 电容层析成像(ECT) 根据不同相的介电常数差异,记录多对测量电极间的电场变化,通过层析重构算法计算出流场中的介电常数分布,进而还原各相组分分布 气液两相组分的空间分布和两相宏观运动规律 测量响应快速,实验装置安全,测试系统廉价易得 空间分辨率较低;因测量电极布置的限制,目前仅适用于圆管中的内流测量 磁共振成像/测速(MRI/MRV) 物质原子核内质子在外加磁场作用下发生进动,发射射频脉冲使质子发生核磁共振;当射频脉冲移除后,被激发的共振质子经弛豫过程,以发射电磁波的形式释放能量,根据弛豫时间和质子密度的差异,实现不同相的磁共振成像 空泡内部的含汽率和

速度分布对流场干扰小,安全无辐射,时间和空间分辨率较高 磁共振信号对温度敏感;需将流场布置在磁共振仪内部,实验条件要求较高 电阻多相流探针 根据探针尖端铂丝在水和汽泡中阻抗的明显差异,在测量回路中获得区分水/汽的电压信号;由邻近2根铂丝的信号延迟得到汽泡速度和泡径等信息 单点的含汽率、汽泡速度和汽泡尺度 汽泡测量的时间分辨率高;可分别获得单泡信息和群泡的统计分布规律 探针尖端对局部流场有轻微扰动;尖端处需要2根铂丝彼此绝缘,对加工精度要求较高 光纤多相流探针 根据探针尖端二氧化硅材料在水和汽泡中折射率的差异,通过激光折射/反射不同光强的光信号获得区分水/汽的电压信号;由信号抬升时间和停留时间计算汽泡速度和泡径等信息 单点的含汽率、汽泡速度和汽泡尺度 输出信号稳定,受电学干扰较小;汽泡测量的时间分辨率高;可分别获得单泡信息和群泡的统计分布规律 探针尖端对局部流场有轻微扰动;对探针加工技术要求高,尖端处易受损 -

[1] TORTORA P R, CECCIO S L, O’HERN T J, et al. Quantitative measurement of solids distribution in gas–solid riser flows using electrical impedance tomography and gamma densitometry tomography[J]. International Journal of Multiphase Flow, 2006, 32(8): 972–995. doi: 10.1016/j.ijmultiphaseflow.2006.03.004 [2] COUTIER-DELGOSHA O, STUTZ B, VABRE A, et al. Analysis of cavitating flow structure by experimental and numerical investigations[J]. Journal of Fluid Mechanics, 2007, 578: 171–222. doi: 10.1017/s0022112007004934 [3] MÄKIHARJU S A, PERLIN M, CECCIO S L. Time resolved X-ray densitometry for cavitating and ventilated partial cavities[J]. International Shipbuilding Progress, 2013, 60(1-4): 471–494. [4] GANESH H, MÄKIHARJU S A, CECCIO S L. Bubbly shock propagation as a mechanism for sheet-to-cloud transition of partial cavities[J]. Journal of Fluid Mechanics, 2016, 802: 37–78. doi: 10.1017/jfm.2016.425 [5] ZHANG G J, KHLIFA I, FEZZAA K, et al. Experimental investigation of internal two-phase flow structures and dynamics of quasi-stable sheet cavitation by fast synchrotron X-ray imaging[J]. Physics of Fluids, 2020, 32(11): 113310. doi: 10.1063/5.0029963 [6] ZHANG G J, KHLIFA I, COUTIER-DELGOSHA O. A comparative study of quasi-stable sheet cavities at different stages based on fast synchrotron X-ray imaging[J]. Physics of Fluids, 2020, 32(12): 123316. doi: 10.1063/5.0031433 [7] ZHANG G J, ZHANG D S, GE M M, et al. Experimental investigation of three distinct mechanisms for the transition from sheet to cloud cavitation[J]. International Journal of Heat and Mass Transfer, 2022, 197(1): 123372. doi: 10.1016/j.ijheatmasstransfer.2022.123372 [8] STUTZ B, LEGOUPIL S. X-ray measurements within unsteady cavitation[J]. Experiments in Fluids, 2003, 35(2): 130–138. doi: 10.1007/s00348-003-0622-0 [9] COUTIER-DELGOSHA O, DEVILLERS J F, PICHON T, et al. Internal structure and dynamics of sheet cavitation[J]. Physics of Fluids, 2006, 18(1): 017103. doi: 10.1063/1.2149882 [10] AESCHLIMANN V, BARRE S, LEGOUPIL S. X-ray attenuation measurements in a cavitating mixing layer for instantaneous two-dimensional void ratio determination[J]. Physics of Fluids, 2011, 23(5): 055101. doi: 10.1063/1.3586801 [11] 陆芳, 陆林章, 庞业珍, 等. 实船螺旋桨空泡观测[C]//第十三届全国水动力学学术会议暨第二十六届全国水动力学研讨会论文集. 2014. [12] MARASHDEH Q, FAN L S, DU B, et al. Electrical capacitance tomography – A perspective[J]. Industrial & Engineering Chemistry Research, 2008, 47(10): 3708–3719. doi: 10.1021/ie0713590 [13] ADAM M S, YANG W Q, WATSON R. A capacitance tomographic system for the measurement of void fraction in transient cavitation[J]. Journal of Hydraulic Research, 1998, 36(4): 707–719. doi: 10.1080/00221689809498617 [14] BANASIAK R, WAJMAN R, JAWORSKI T, et al. Study on two-phase flow regime visualization and identification using 3D electrical capacitance tomography and fuzzy-logic classification[J]. International Journal of Multiphase Flow, 2014, 58: 1–14. doi: 10.1016/j.ijmultiphaseflow.2013.07.003 [15] AL HOSANI E. Electrical capacitance tomography for real-time monitoring of process pipelines[D]. Bath: University of Bath, 2016. [16] 邓峰, 熊春明, 陈诗雯, 等. 油气多相流磁共振在线检测方法及装置[J]. 石油勘探与开发, 2020, 47(4): 798–808. doi: 10.11698/PED.2020.04.17DENG F, XIONG C M, CHEN S W, et al. A method and device for online magnetic resonance multiphase flow detection[J]. Petroleum Exploration and Development, 2020, 47(4): 798–808. doi: 10.11698/PED.2020.04.17 [17] 袁景峰. 核磁共振两相流测量方法与系统研究[D]. 西安: 西安石油大学, 2020.YUAN J F. Research on measurement method and system of NMR two-phase flow[D]. Xi'an: Xi'an Shiyou University, 2020. [18] 赵喜平. 磁共振成像[M]. 北京: 科学出版社, 2004. [19] BROWN R W, CHENG Y C N, HAACKE E M, et al. Magnetic Resonance Imaging: Physical Principles and Sequence Design[M]. Chichester: John Wiley & Sons Ltd, 2014. doi: 10.1002/9781118633953 [20] ARBABI A, MASTIKHIN I V. Magnetic susceptibility based magnetic resonance estimation of micro-bubble size for the vertically upward bubbly flow[J]. Journal of Magnetic Resonance, 2012, 225: 36–45. doi: 10.1016/j.jmr.2012.09.012 [21] MASTIKHIN I, ARBABI A, BADE K M. Magnetic Resonance Imaging measurements of a water spray upstream and downstream of a spray nozzle exit orifice[J]. Journal of Magnetic Resonance, 2016, 266: 8–15. doi: 10.1016/j.jmr.2016.03.005 [22] MASTIKHIN I V, ARBABI A, NEWLING B, et al. Magnetic resonance imaging of velocity fields, the void fraction and gas dynamics in a cavitating liquid[J]. Experiments in Fluids, 2012, 52(1): 95–104. doi: 10.1007/s00348-011-1209-9 [23] ARBABI A. Magnetic resonance study of two-phase gas-liquid systems[D]. Fredericton: University of New Brunswick, 2015. [24] ADAIR A, MASTIKHIN I V, NEWLING B. Motion-sensitized SPRITE measurements of hydrodynamic cavitation in fast pipe flow[J]. Magnetic Resonance Imaging, 2018, 49: 71–77. doi: 10.1016/j.mri.2017.12.025 [25] JOHN K, BRUSCHEWSKI M, JAHANGIR S, et al. Mean flow field measurements in cavitating flow using magnetic resonance velocimetry supported by X-ray and particle image velocimetry[C]//Proc of the APS Division of Fluid Dynamics Meeting Abstracts. 2019. [26] 朱礼涛, 罗正鸿. 磁共振成像应用于多相流体动力学研究进展[J]. 化工学报, 2018, 69(9): 3765–3773. doi: 10.11949/j.issn.0438-1157.20180192ZHU L T, LUO Z H. Application of magnetic resonance imaging to multiphase fluid hydrodynamics[J]. CIESC Journal, 2018, 69(9): 3765–3773. doi: 10.11949/j.issn.0438-1157.20180192 [27] 郭春雨, 郐云飞, 韩阳, 等. 舰船流场试验测试技术研究进展[J]. 中国舰船研究, 2022, 17(5): 103–115. doi: 10.19693/j.issn.1673-3185.02857GUO C Y, KUAI Y F, HAN Y, et al. Review of research on ship flow field measurement technology[J]. Chinese Journal of Ship Research, 2022, 17(5): 103–115. doi: 10.19693/j.issn.1673-3185.02857 [28] NEAL L G, BANKOFF S G. A high resolution resistivity probe for determination of local void properties in gas-liquid flow[J]. AIChE Journal, 1963, 9(4): 490–494. doi: 10.1002/aic.690090415 [29] MILLER N, MITCHIE R E. Measurement of local voidage in liquid/gas two-phase flow systems using a universal probe[J]. Journal of the British Nuclear Energy Society, 1970, 9(2): 94–100. [30] ABUAF N, JONES O C Jr, ZIMMER G A. Optical probe for local void fraction and interface velocity measure-ments[J]. Review of Scientific Instruments, 1978, 49(8): 1090–1094. doi: 10.1063/1.1135524 [31] CARTELLIER A, ACHARD J L. Local phase detection probes in fluid/fluid two-phase flows[J]. Review of Scientific Instruments, 1991, 62(2): 279–303. doi: 10.1063/1.1142117 [32] CARTELLIER A. Optical probes for local void fraction measurements: characterization of performance[J]. Review of Scientific Instruments, 1990, 61(2): 874–886. doi: 10.1063/1.1141457 [33] CARTELLIER A. Simultaneous void fraction measurement, bubble velocity, and size estimate using a single optical probe in gas-liquid two-phase flows[J]. Review of Scientific Instruments, 1992, 63(11): 5442–5453. doi: 10.1063/1.1143416 [34] CARTELLIER A, BARRAU E. Monofiber optical probes for gas detection and gas velocity measurements: conical probes[J]. International Journal of Multiphase Flow, 1998, 24: 1265–1294. doi: 10.1016/S0301-9322(98)00032-9 [35] CARTELLIER A, BARRAU E. Monofiber optical probes for gas detection and gas velocity measurements: optimized sensing tips[J]. International Journal of Multiphase Flow, 1998, 24: 1295–1315. doi: 10.1016/S0301-9322(98)00033-0 [36] CARTELLIER A. Measurement of gas phase characteristics using new monofiber optical probes and real-time signal processing[J]. Nuclear Engineering and Design, 1998, 184: 393–408. doi: 10.1016/S0029-5493(98)00211-8 [37] CARTELLIER A. Post-treatment for phase detection probes in non uniform two-phase flows[J]. International Journal of Multiphase Flow, 1999, 25(2): 201–228. doi: 10.1016/S0301-9322(98)00041-X [38] BARRAU E, RIVIÈRE N, POUPOT Ch. Single and double optical probes in air-water two-phase flows: real time signal processing and sensor performance[J]. International Journal of Multiphase Flow, 1999, 25(2): 229–256. doi: 10.1016/S0301-9322(98)00042-1 [39] STUTZ B, REBOUD J L. Experiments on unsteady cavitation[J]. Experiments in Fluids, 1997, 22(3): 191–198. doi: 10.1007/s003480050037 [40] STUTZ B, REBOUD J L. Two-phase flow structure of sheet cavitation[J]. Physics of Fluids, 1997, 9(12): 3678–3686. doi: 10.1063/1.869505 [41] LUTHER S, RENSEN J, GUET S. Bubble aspect ratio and velocity measurement using a four-point fiber-optical probe[J]. Experiments in Fluids, 2004, 36(2): 326–333. doi: 10.1007/s00348-003-0725-7 [42] SUN X, VASAVADA S, CHOI S W, et al. Interfacial structure in an air-water planar bubble jet[J]. Experiments in Fluids, 2005, 38(4): 426–439. doi: 10.1007/s00348-004-0921-0 [43] ENRIQUE JULIÁ J, HARTEVELD W K, MUDDE R F, et al. On the accuracy of the void fraction measurements using optical probes in bubbly flows[J]. Review of Scientific Instruments, 2005, 76(3): 035103. doi: 10.1063/1.1862192 [44] VEJRAŽKA J, VEČEŘ M, ORVALHO S, et al. Measurement accuracy of a mono-fiber optical probe in a bubbly flow[J]. International Journal of Multiphase Flow, 2010, 36(7): 533–548. doi: 10.1016/j.ijmultiphaseflow.2010.03.007 [45] ROJAS G, LOEWEN M R. Fiber-optic probe measurements of void fraction and bubble size distributions beneath breaking waves[J]. Experiments in Fluids, 2007, 43(6): 895–906. doi: 10.1007/s00348-007-0356-5 [46] BLENKINSOPP C E, CHAPLIN J R. Bubble size measurements in breaking waves using optical fiber phase detection probes[J]. IEEE Journal of Oceanic Engineering, 2010, 35(2): 388–401. doi: 10.1109/JOE.2010.2044940 [47] HONG M, CARTELLIER A, HOPFINGER E J. Characterization of phase detection optical probes for the measurement of the dispersed phase parameters in sprays[J]. International Journal of Multiphase Flow, 2004, 30(6): 615–648. doi: 10.1016/j.ijmultiphaseflow.2004.04.004 [48] FELDER S, PFISTER M. Comparative analyses of phase-detective intrusive probes in high-velocity air–water flows[J]. International Journal of Multiphase Flow, 2017, 90: 88–101. doi: 10.1016/j.ijmultiphaseflow.2016.12.009 [49] HERNANDEZ-ALVARADO F, KLEINBART S, KALAGA D V, et al. Comparison of void fraction measurements using different techniques in two-phase flow bubble column reactors[J]. International Journal of Multiphase Flow, 2018, 102: 119–129. doi: 10.1016/j.ijmultiphaseflow.2018.02.002 [50] WAN C R, WANG B L, WANG Q, et al. Probing and imaging of vapor-water mixture properties inside partial/cloud cavitating flows[J]. Journal of Fluids Engineering, 2017, 139(3): 031303. doi: 10.1115/1.4035013 [51] ZHANG H, LIU Y Q, WANG B L, et al. Phase-resolved characteristics of bubbles in cloud cavitation shedding cycles[J]. Ocean Engineering, 2022, 256: 111529. doi: 10.1016/j.oceaneng.2022.111529 [52] DIAS S G, FRANCA F A, ROSA E S. Statistical method to calculate local interfacial variables in two-phase bubbly flows using intrusive crossing probes[J]. International Journal of Multiphase Flow, 2000, 26(11): 1797–1830. doi: 10.1016/S0301-9322(99)00111-1 [53] LIU Y Q, ZHANG H, ZHANG W, et al. Bubble size distribution at early stage of hydrodynamic cloud cavitation[J]. Physics of Fluids, 2023, 35: 063305. doi: 10.1063/5.0154309 -

下载:

下载: