| [1] |

乔渭阳, 王良锋. 航空发动机气动声学[M]. 2版. 西安: 西北工业大学出版社, 2016.

|

| [2] |

BU H X, HUANG X, ZHANG X. An overview of testing methods for aeroengine fan noise[J]. Progress in Aerospace Sciences, 2021, 124: 100722. doi: 10.1016/j.paerosci.2021.100722

|

| [3] |

SEINER J M, REETHOF G. Design and development of the spinning mode synthesizer[M]. Washington: National Aeronautics and Space Administration, 1973.

|

| [4] |

BERTSCH L, SNELLEN M, ENGHARDT L, et al. Aircraft noise generation and assessment: executive summary[J]. CEAS Aeronautical Journal, 2019, 10(1): 3–9. doi: 10.1007/s13272-019-00384-3

|

| [5] |

BACCOUCHE R, MOREAU S, BEN M. Test of single degree of freedom acoustic treatment impedance models for multimodal acoustic propagation in duct with flow[J]. The Journal of the Acoustical Society of America, 2017, 141(6): 4168–4178. doi: 10.1121/1.4983653

|

| [6] |

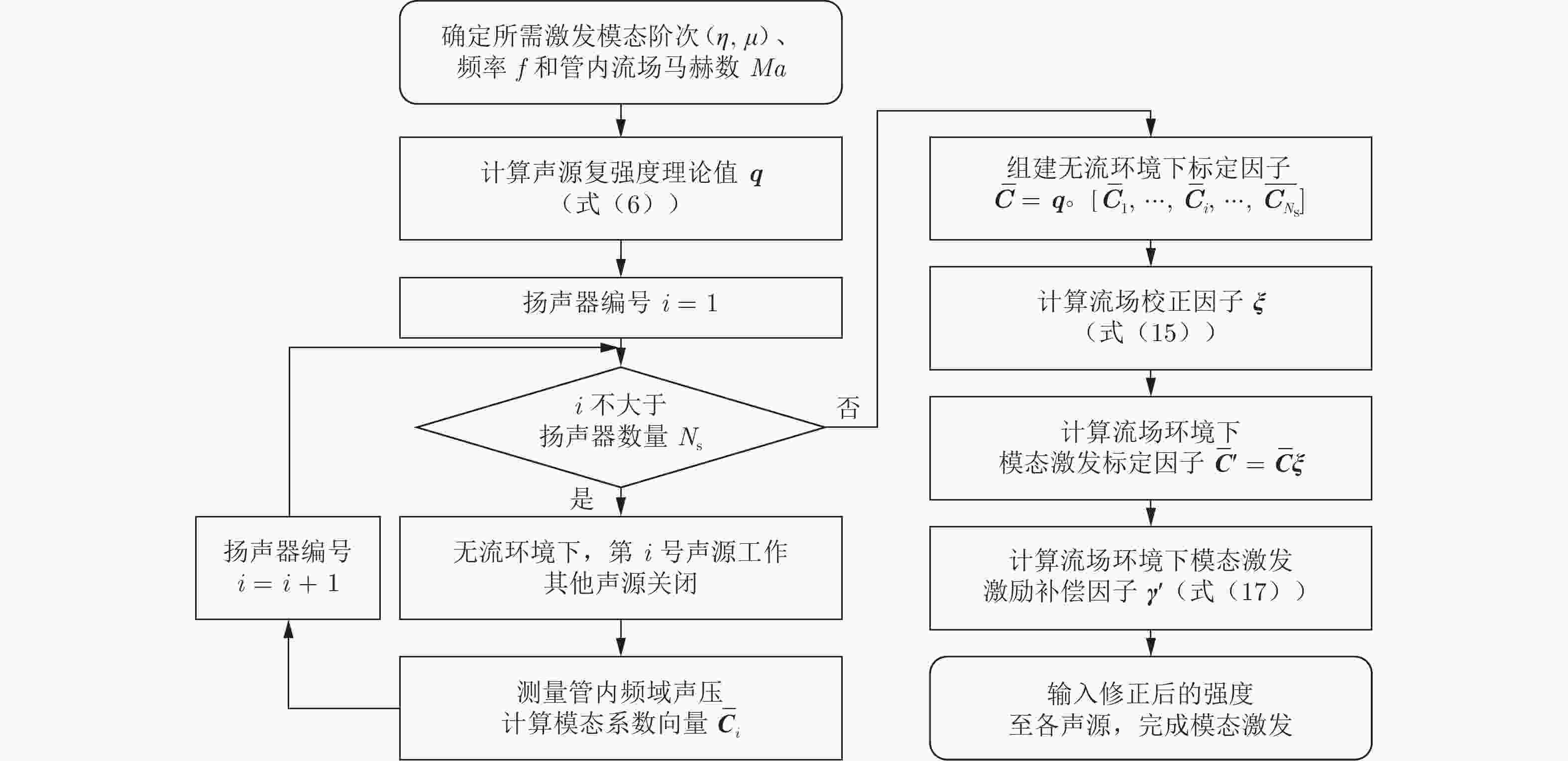

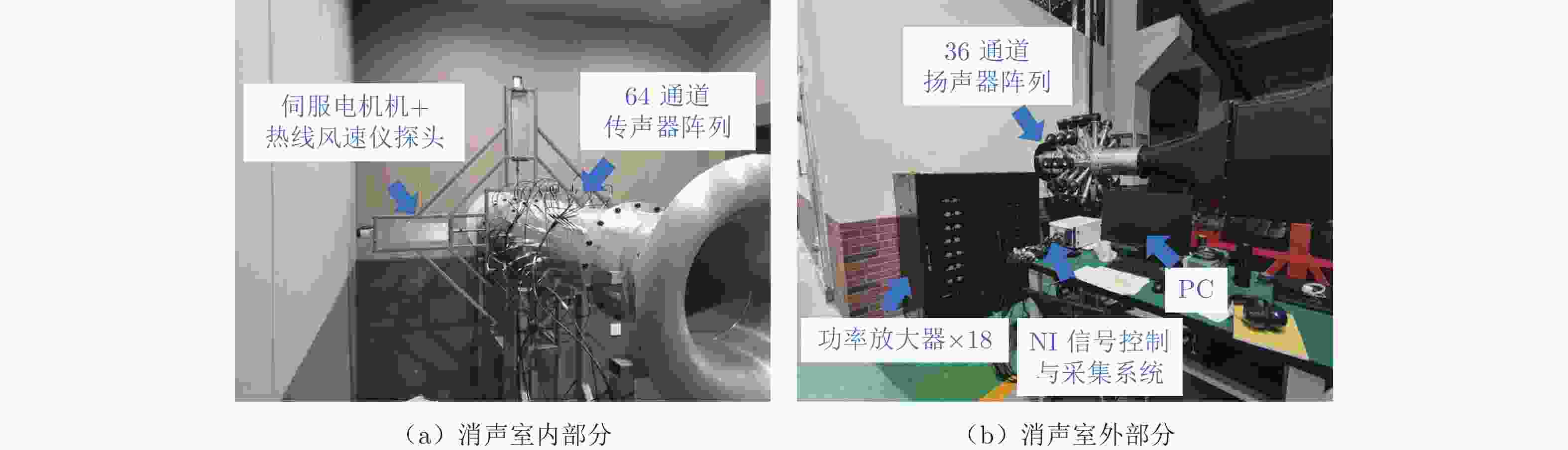

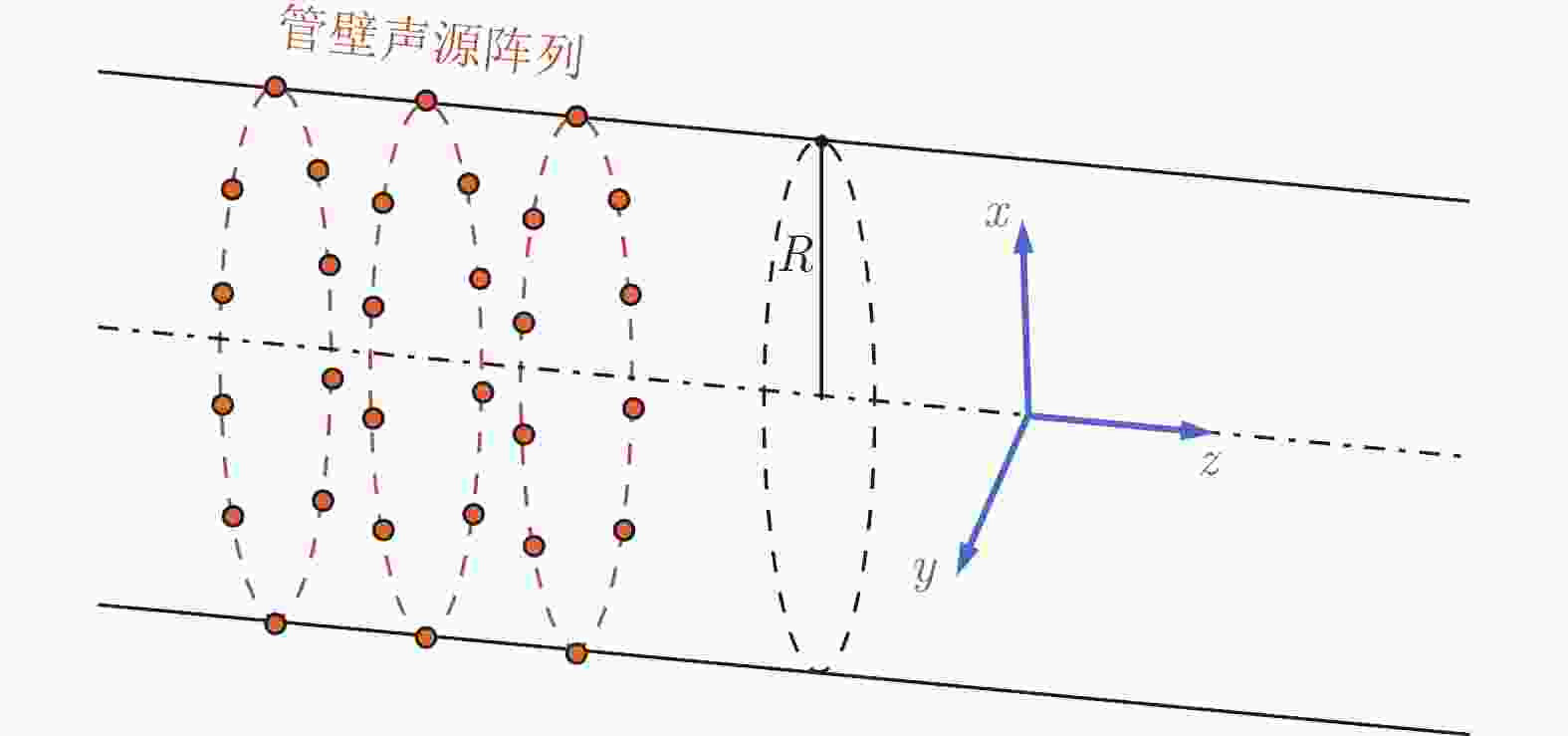

张涛, 林大楷, 张颖哲, 等. 基于模态发生器的进气道风扇噪声及声衬降噪实验[J]. 航空动力学报, 2021, 36(2): 240–248. doi: 10.13224/j.cnki.jasp.2021.02.003ZHANG T, LIN D K, ZHANG Y Z, et al. Experiment of intake fan noise and noise reduction of acoustic liner based on mode generator[J]. Journal of Aerospace Power, 2021, 36(2): 240–248. doi: 10.13224/j.cnki.jasp.2021.02.003

|

| [7] |

PALUMBO D L. An operations manual for the Spinning Mode Synthesizer in the Langley Aircraft Noise Reduction Laboratory[R]. NASA-CR-165698, 1981.

|

| [8] |

BÖHNING P, ARNOLD F, HOLSTE F, et al. Aerodynamic duct mode generator[C]//Proc of the 13th AIAA/CEAS Aeroacoustics Conference (28th AIAA Aeroacoustics Conference). 2007. doi: 10.2514/6.2007-3433

|

| [9] |

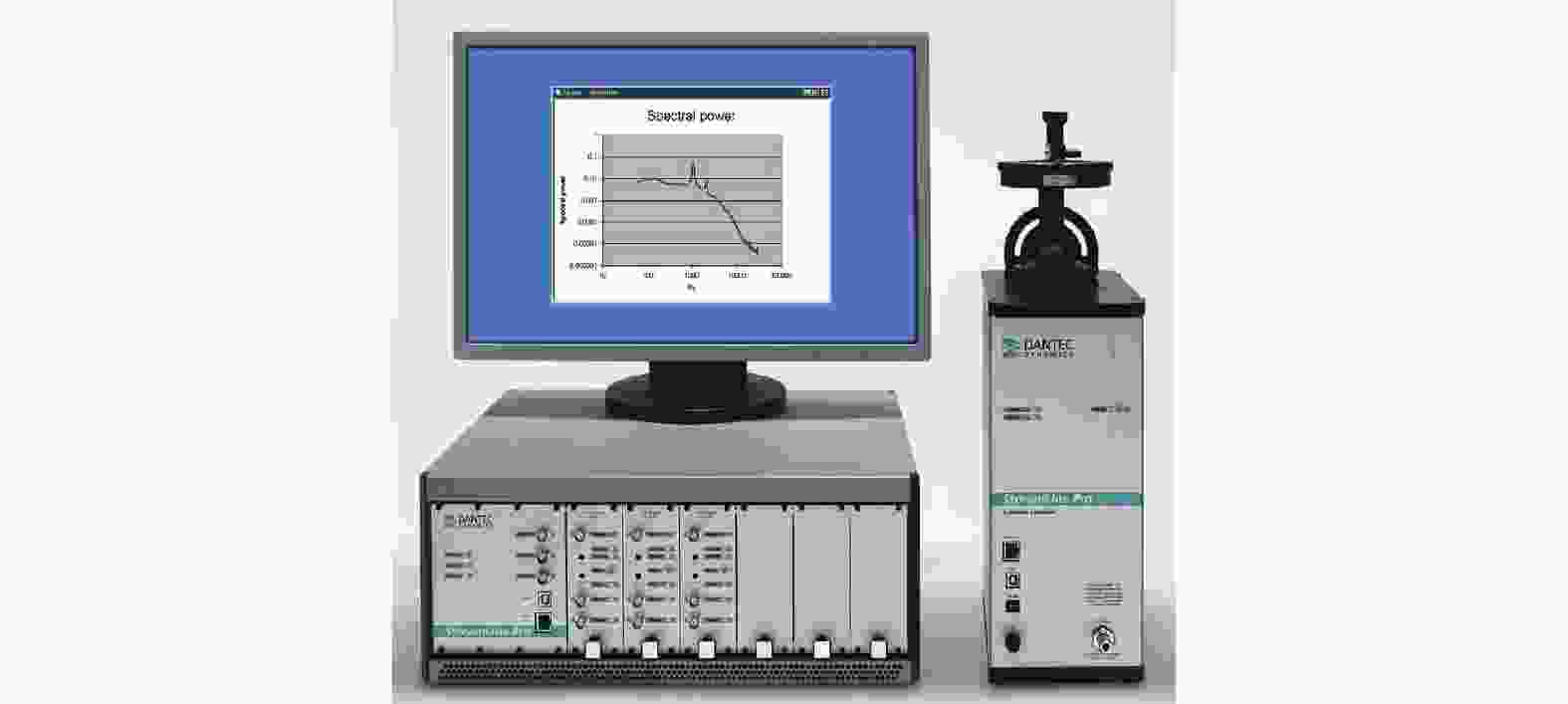

高翔, 薛东文, 燕群, 等. 涡扇发动机旋转声模态发生与测试试验研究[J]. 科学技术与工程, 2018, 18(23): 128–133. doi: 10.3969/j.issn.1671-1815.2018.23.018GAO X, XUE D W, YAN Q, et al. Research on acoustic spinning mode synthesizer and measurement of turbofan engine method validating experiment[J]. Science Technology and Engineering, 2018, 18(23): 128–133. doi: 10.3969/j.issn.1671-1815.2018.23.018

|

| [10] |

SUTLIFF D L, JONES M G, NARK D M. In-duct and farfield experimental measurements from the ancf for the purpose of improved broadband liner optimization[C]// Proc of the 20th AIAA/CEAS Aeroacoustics Conference. 2014. doi: 10.2514/6.2014-3231

|

| [11] |

MUMCU A, KELLER C, HURFAR C M, et al. An acoustic excitation system for the generation of turbomachinery specific sound fields: part I—design and methodology[C]//Proceedings of ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition. 2016. doi: 10.1115/GT2016-56020

|

| [12] |

HURFAR C M, KELLER C, MUMCU A, et al. An acoustic excitation system for the generation of turbomachinery specific sound fields: part II—experimental verification[C]//Proceedings of ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition. 2016 doi: 10.1115/GT2016-56969

|

| [13] |

薛东文, 燕群, 高翔, 等. 发动机涵道高阶声模态控制技术研究[J]. 计算机仿真, 2019, 36(6): 125–130, 185. doi: 10.3969/j.issn.1006-9348.2019.06.025XUE D W, YAN Q, GAO X, et al. The control of high order acoustic modes in engine duct[J]. Computer Simulation, 2019, 36(6): 125–130, 185. doi: 10.3969/j.issn.1006-9348.2019.06.025

|

| [14] |

SUTLIFF D L, WALKER B E. Artificial noise systems for parametric studies of turbo-machinery aero-acoustics[J]. International Journal of Aeroacoustics, 2016, 15(1-2): 103–130. doi: 10.1177/1475472x16630851

|

| [15] |

ARNOLD F, TAPKEN U, BAUERS R, et al. Turbomachinery exhaust noise radiation experiments - part 1: polar directivity measurements[C]//Proc of the 14th AIAA/CEAS Aeroacoustics Conference (29th AIAA Aeroacoustics Conference). 2008. doi: 10.2514/6.2008-2857

|

| [16] |

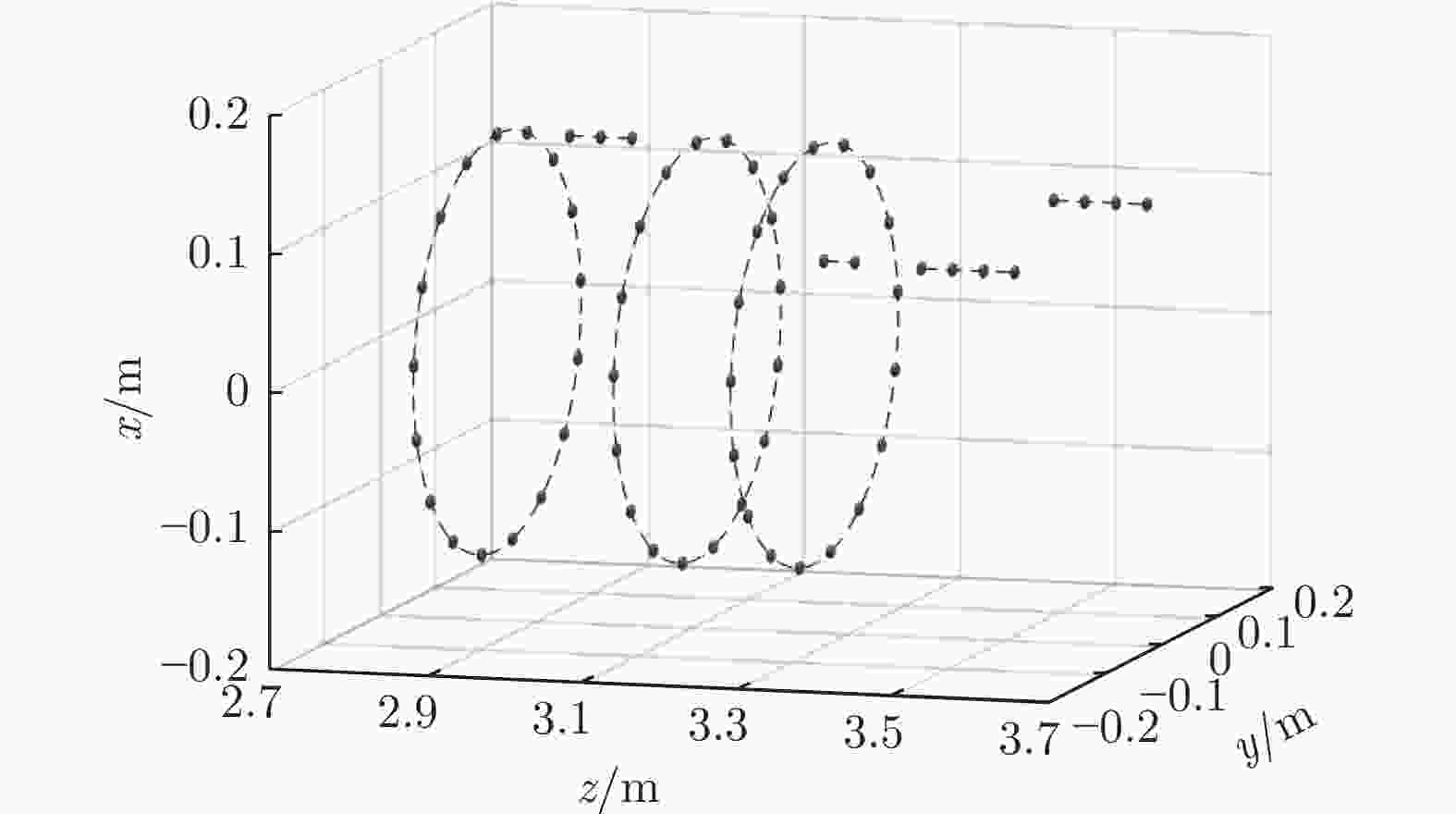

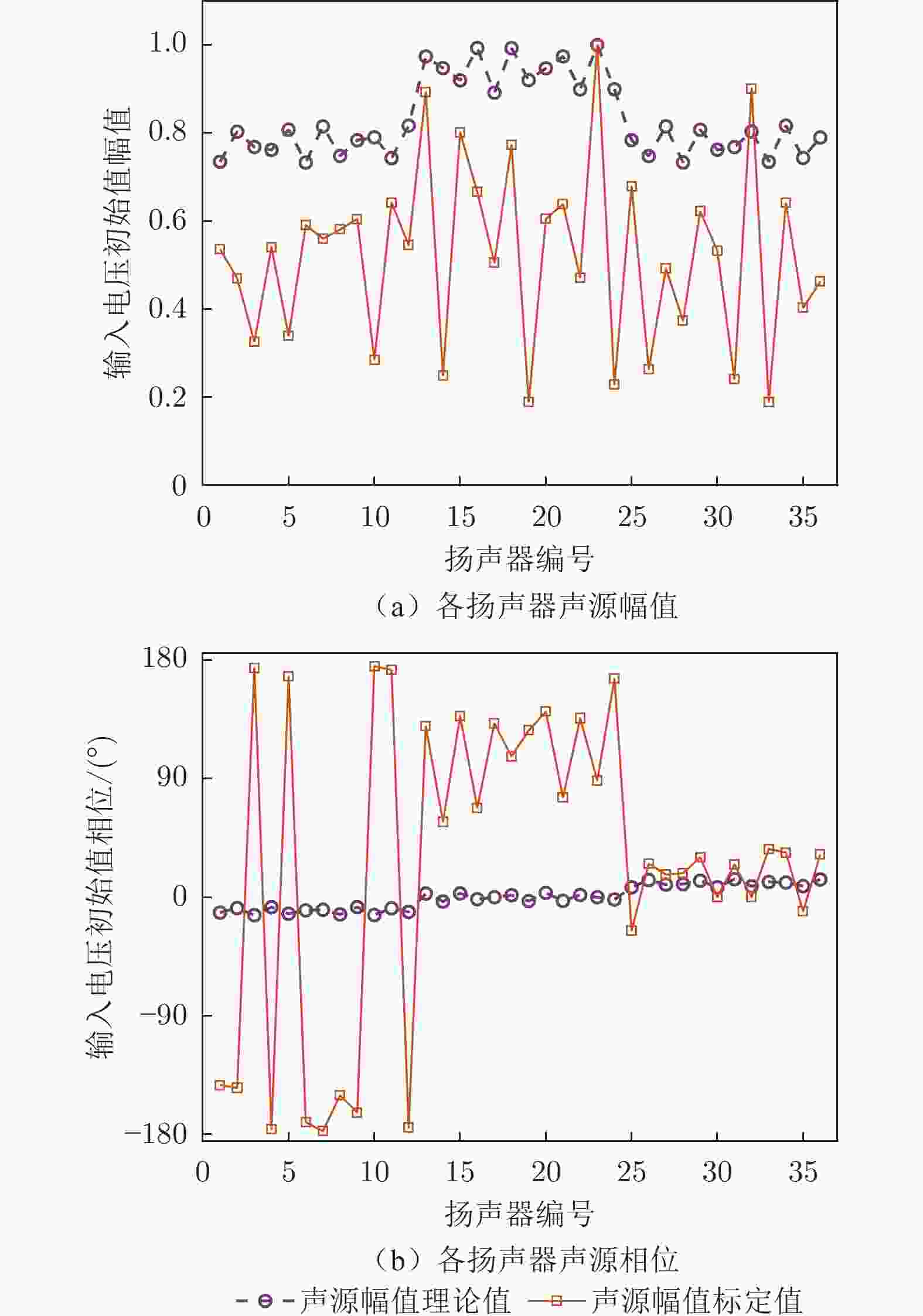

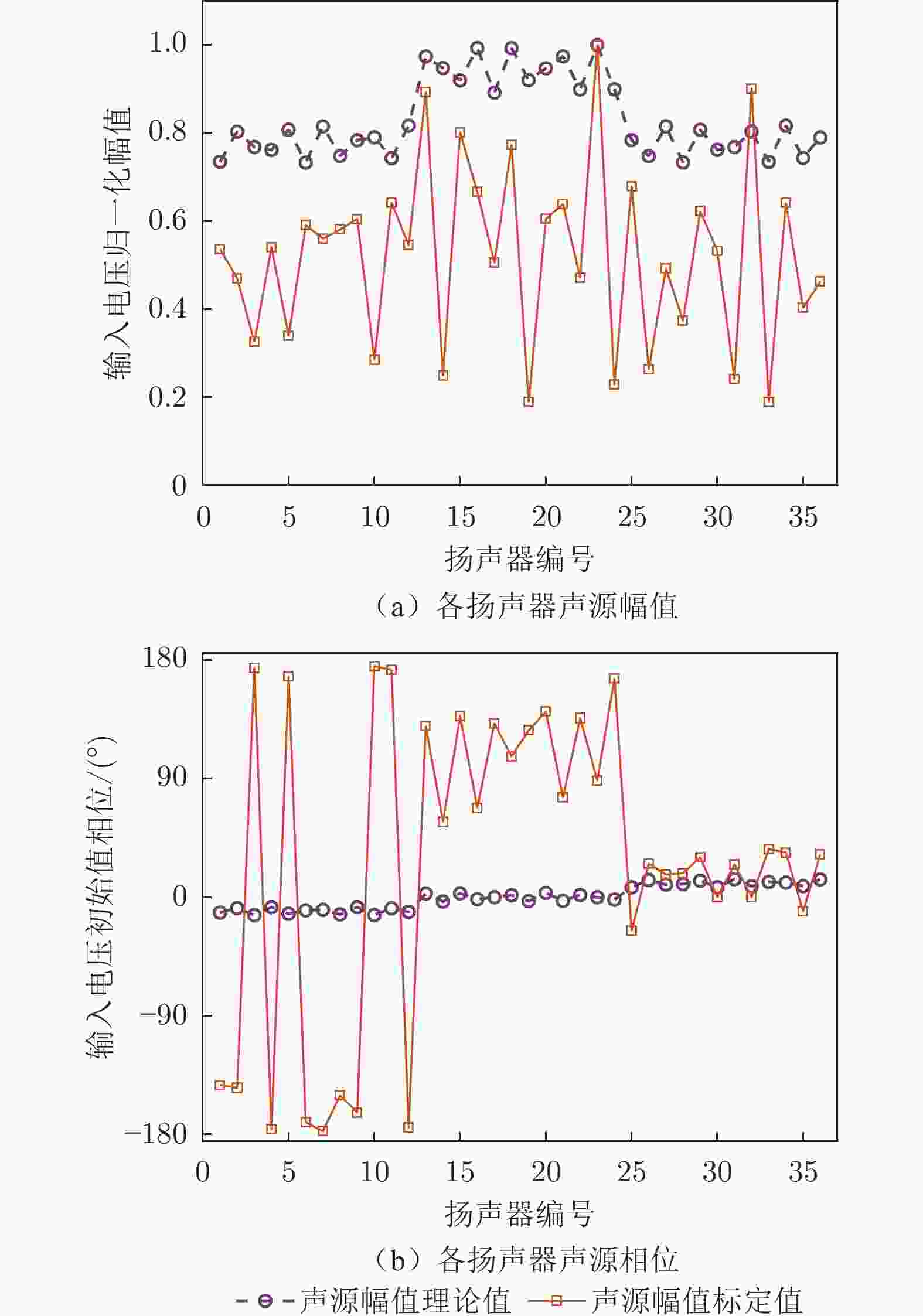

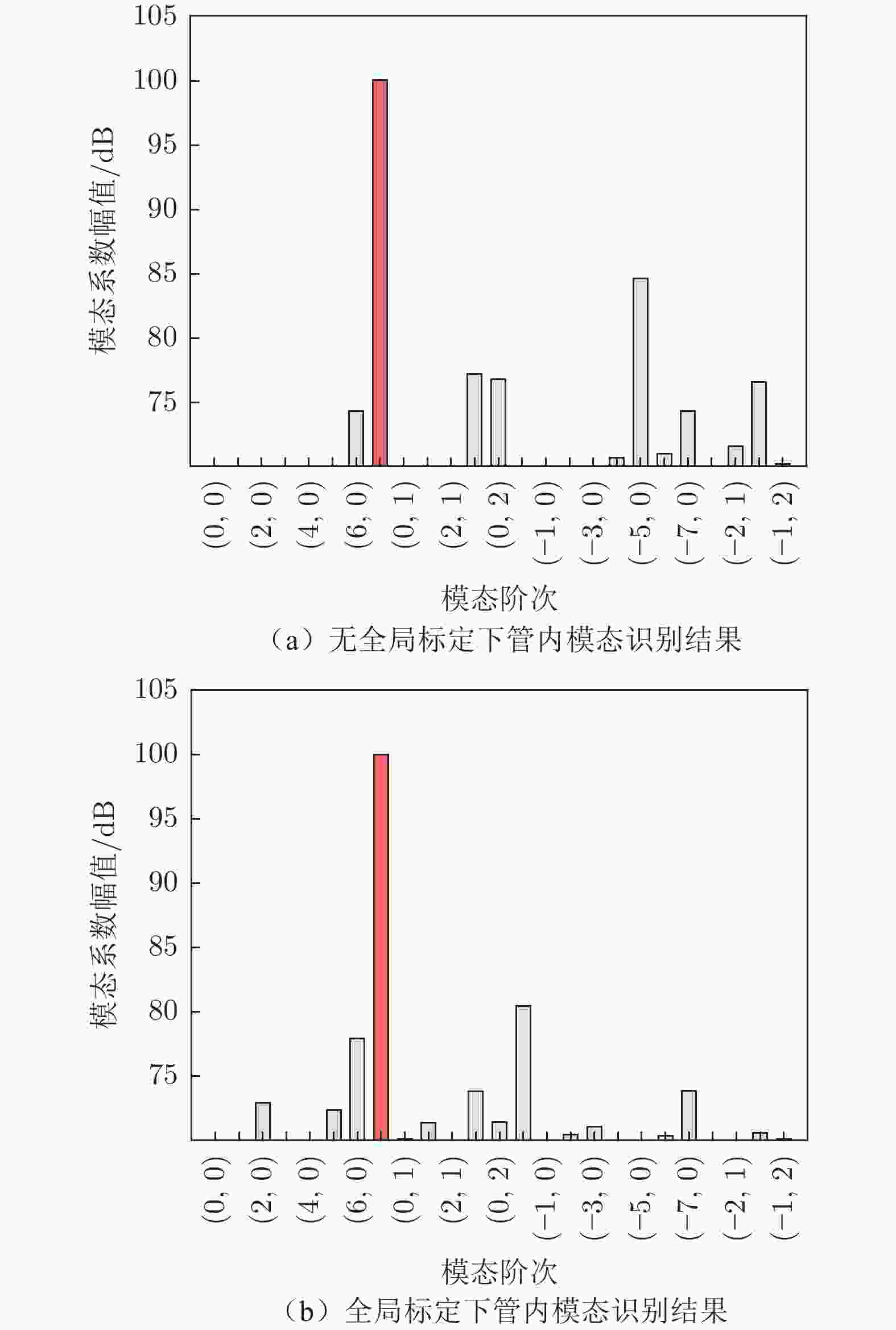

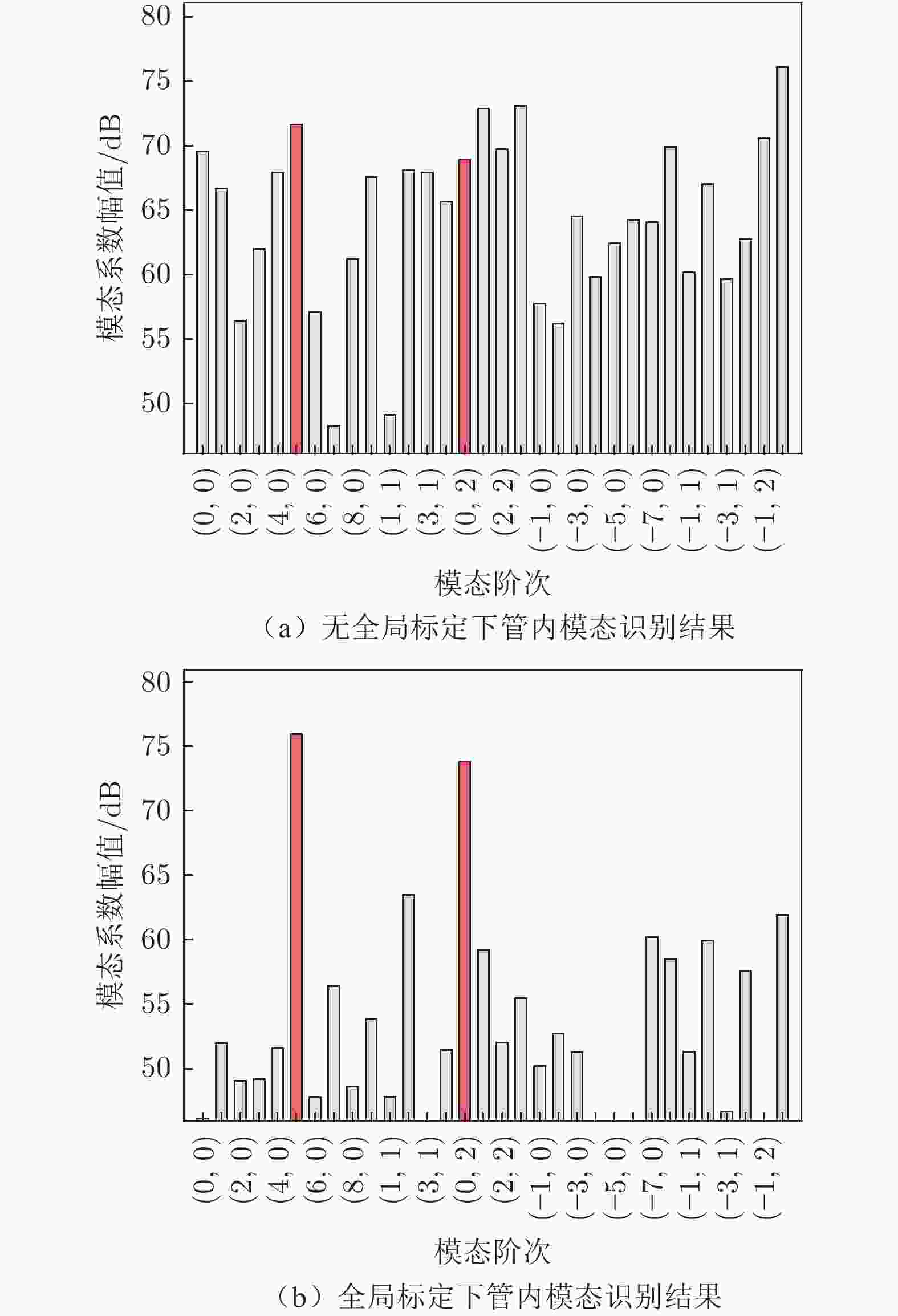

黄时春, 英基勇, 高翔, 等. 激发圆形管道内多阶声模态的扬声器阵列控制方法[J]. 声学学报, 2022, 47(4): 521–530. doi: 10.15949/j.cnki.0371-0025.2022.04.005HUANG S C, YING J Y, GAO X, et al. A loudspeaker array control method for exciting multi-order acoustic modes in a cylindrical duct[J]. Acta Acustica, 2022, 47(4): 521–530. doi: 10.15949/j.cnki.0371-0025.2022.04.005

|

| [17] |

HUANG S, PAN X, YU L, et al. Achieving cylindrical duct modes generation in spinning mode synthesizer via a least-square identification of the global calibration factor[J]. Applied Acoustics, 2022, 186: 108423. doi: 10.1016/j.apacoust.2021.108423

|

| [18] |

ALONSO J S, BURDISSO R A. Green's functions for the acoustic field in lined ducts with uniform flow[J]. AIAA Journal, 2007, 45(11): 2677–2687. doi: 10.2514/1.29872

|

| [19] |

LOWIS C, JOSEPH P. A focused beamformer technique for separating rotor and stator-based broadband sources[C]//Proc of the 12th AIAA/CEAS Aeroacoustics Conference (27th AIAA Aeroacoustics Conference). 2006. doi: 10.2514/6.2006-2710

|

| [20] |

TIKHONOV A. Solution of incorrectly formulated problems and the regularization method[J]. Soviet Math, 1963, 4: 1035–1038.

|

| [21] |

黄时春. 圆形管道内复杂声模态的激发与识别[D]. 上海: 上海交通大学, 2021.

|

| [22] |

HILL G. Loudspeaker modelling and design: a practical introduction[M]. New York: Routledge, 2019.

|

下载:

下载: