The dynamic calibration method of PSP and its characteristics research considering the influence of temperature

-

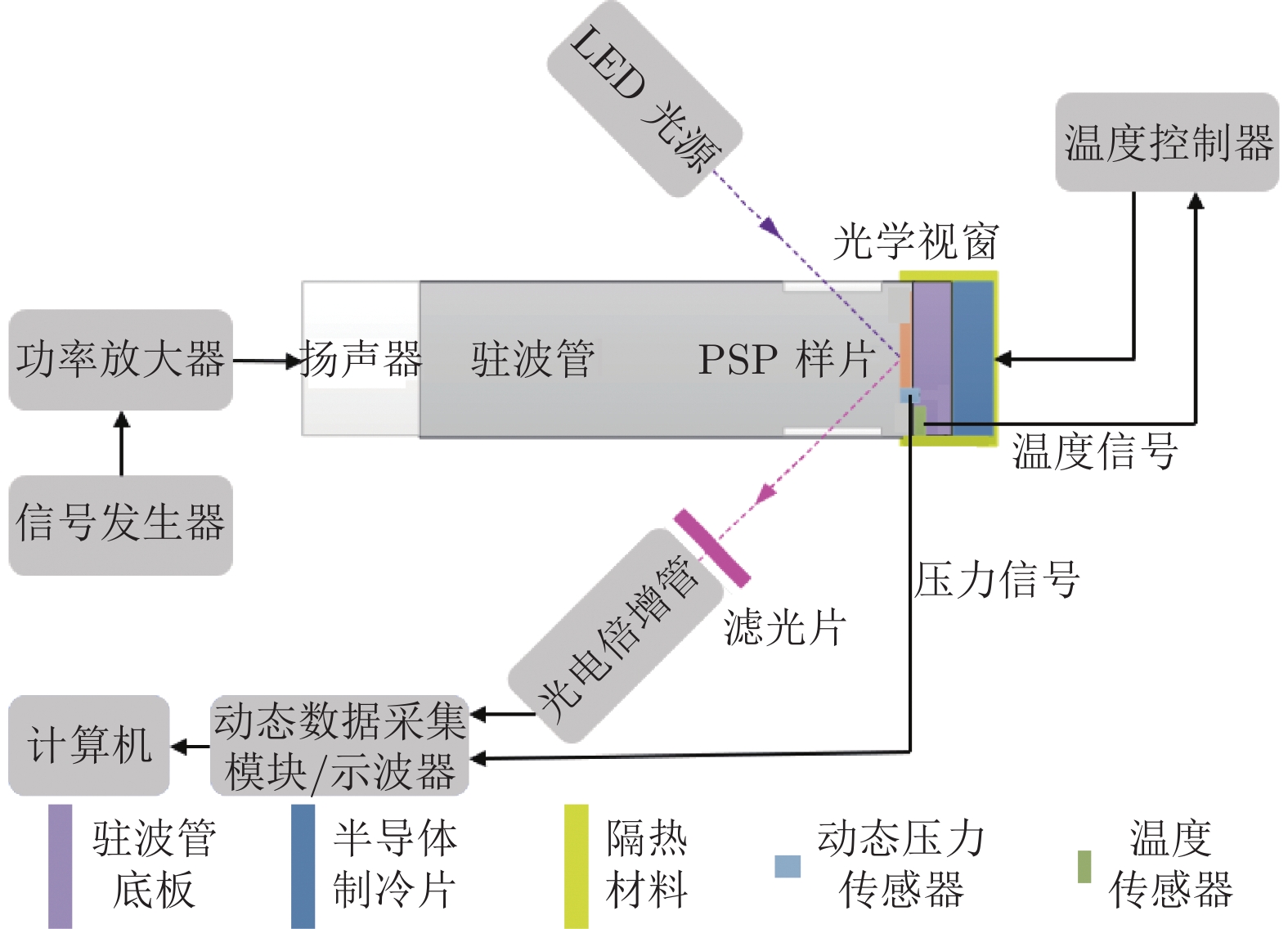

摘要: 快响应压敏涂料( Pressure-Sensitive Paint, PSP)的动态特性及温度对其影响规律是决定快响应PSP是否适用于非定常流场的关键依据。本文提出了快响应PSP动态校准方法,采用能够调节温度和频率的动态校准系统建立可控校准驻波场,系统开展了温度对所研制的聚合物陶瓷压敏涂料(Polymer Ceramic Pressure-Sensitive Paint, PC-PSP)压力灵敏度和频响特性的影响研究。动态校准比静态校准能够更为准确地反映快响应涂料的特性。频率变化对PC-PSP压力灵敏度有显著影响;温度对PC-PSP压力灵敏度的影响不明显,但在测量中不可忽视PSP的温度敏感度。同一温度下,随着频率增大,增益减小,相位滞后现象逐渐增强;不同温度下,随着温度升高,截止频率增大,相位滞后现象逐渐减弱。所测试的PC-PSP在20 ℃、0.5 kHz下的动态压力灵敏度为0.59%/kPa,在20 ℃、3.0 kHz下动态压力灵敏度为0.51%/kPa,截止频率为4.8 kHz,性能稳定,满足低速风洞非定常试验的工程要求。Abstract: The dynamic characteristics and temperature effects of fast-response pressure-sensitive paint are the key factors for determining whether it is applicable to unsteady flow fields. This paper proposes a method for dynamic calibration of fast-response PSP (Pressure-Sensitive Paint), establishes a controllable calibration standing wave field through a dynamic calibration system that can adjust the temperature and frequency, and researches on the influence of temperature on pressure sensitivity and frequency response characteristics of the developed PC-PSP (Polymer Ceramic Pressure-Sensitive Paint). Dynamic calibration reflects the PSP characteris-tics more accurately than static calibration. Frequency changes have a significant effect on the pressure sensitivity of PC-PSP, and the influence of temperature on the pressure sensitivity of PC-PSP is not significant, while the temperature sensitivity of PC-PSP cannot be ignored in measure-ment. At the same temperature, the gain decreases and the phase lags behind as the frequency increases. At different temperatures, with the increase of the temperature, the cut-off frequency increases, and the phase lag gradually weakens. The dynamic pressure sensitivity at 20 ℃ and 0.5 kHz is 0.59%/kPa, and at 20 ℃ and 3 kHz is 0.51%/kPa, with the cut-off frequency being 4.8 kHz. Therefore, the performance of the tested PC-PSP is stable and meets the engineering requirements for unsteady flow field pressure measurement tests in low-speed wind tunnels.

-

表 1 校准系统压力–频率表

Table 1. Pressure-frequency table of calibration system

工作频率/kHz 压力/kPa 工作频率/kHz 压力/kPa 0.5 3.647 15 0.242 1.5 5.198 20 0.191 5 2.926 30 0.137 10 1.450 40 0.078 表 2 PC-PSP样片变温压力灵敏度表

Table 2. Pressure sensitivity table of PC-PSP sample with changing temperature

温度/℃ Sp-0.5/(%·kPa−1) Sp-3/(%·kPa−1) 1−Sp-3/Sp-0.5 10 0.57 0.44 22.8% 20 0.59 0.51 13.6% 30 0.57 0.50 12.3% 40 0.58 0.52 10.3% -

[1] PETERSON J I, FITZGERALD R V. New technique of surface flow visualization based on oxygen quenching of fluorescence[J]. Review of Scientific Instruments, 1980, 51(5):670–671. doi: 10.1063/1.1136277 [2] 战培国. 动态压敏漆技术研究综述[J]. 飞航导弹, 2015(7): 55–59. doi: 10.16338/j.issn.1009-1319.2015.07.12 [3] GREGORY J W, SAKAUE H, LIU T S, et al. Fast pressure-sensitive paint for flow and acoustic diagnostics[J]. Annual Review of Fluid Mechanics, 2014, 46: 303–330. doi: 10.1146/annurev-fluid-010313-141304 [4] DONG Z, LIANG L, ZHANG W G, et al. Simultaneous pressure and deformation field measurement on helicopter rotor blades using a grid-pattern pressure-sensitive paint system[J]. Measurement, 2020, 152: 107359. doi: 10.1016/j.measurement.2019.107359 [5] 魏春华, 仝帆, 廖先辉, 等. 基于快响应压敏漆的螺旋桨表面压力测量技术研究[J]. 气动研究与实验, 2022, 34(2): 53–60. doi: 10.12050/are20220206WEI C H, TONG F, LIAO X H, et al. Research on surface pressure measurement technology of propeller based on fast-sounding Pressure-Sensitive Paint[J]. Aerodynamic Research & Experiment, 2022, 34(2): 53–60. doi: 10.12050/are20220206 [6] NAKAKITA K. Scanning unsteady PSP technique for high-frequency and small-pressure fluctuation in low-speed[C]//Proc of the 27th AIAA Aerodynamic Measurement Technology and Ground Testing Conference. 2010. doi: 10.2514/6.2010-4920 [7] CRAFTON J, FORLINES A, PALLUCONI S, et al. Investigation of transverse jet injections in a supersonic crossflow using fast-responding pressure-sensitive paint[J]. Experiments in Fluids, 2015, 56(2): 1–15. doi: 10.1007/s00348-014-1877-3 [8] GORDEYEV S, DE LUCCA N, JUMPER E J, et al. Comparison of unsteady pressure fields on turrets with different surface features using pressure-sensitive paint[J]. Experiments in Fluids, 2014, 55(1): 1661. doi: 10.1007/s00348-013-1661-9 [9] DAVIS T, EDSTRAND A, ALVI F, et al. Investigation of impinging jet resonant modes using unsteady pressure-sensitive paint measurements[J]. Experiments in Fluids, 2015, 56(5): 101. doi: 10.1007/s00348-015-1976-9 [10] PASTUHOFF M, TILLMARK N, ALFREDSSON P H. Dynamic calibration of polymer/ceramic pressure sensitive paint using a shock tube[C]//Proc of the 7th International Conference on Flow Dynamics. 2010: 132-133. [11] KAMEDA M. Effect of luminescence lifetime on the frequency response of fast-response pressure-sensitive paints[J]. Transactions of The Japan Society of Mechanical Engineers, Part B, 2012, 78(795): 1942–1950. doi: 10.1299/kikaib.78.1942 [12] GREGORY J W, ASAI K, KAMEDA M, et al. A review of pressure-sensitive paint for high-speed and unsteady aerodynamics[J]. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 2008, 222(2): 249-290. doi: 10.1243/09544100jaero243 [13] PANDEY A, GREGORY J W. Frequency-response characteris-tics of polymer/ceramic pressure-sensitive paint[J]. AIAAJournal, 2016, 54(1): 174–185. doi: 10.2514/1.J054166 [14] SUGIMOTO T, KITASHIMA S, NUMATA D, et al. Characterization of frequency response of pressure-sensitive paints[C]//Proc of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition. 2012. doi: 10.2514/6.2012-1185 [15] CASPER K M, WAGNER J L, BERESH S J, et al. Unsteady pressure sensitive paint measurements of resonance properties in complex cavities[C]//Proc of the 46th AIAA Fluid Dynamics Conference. 2016. doi: 10.2514/6.2016-3315 [16] McMULLEN R M, HUYNH D P, GREGORY J, et al. Dynamic calibrations for fast-response porous polymer/ceramic pressure-sensitive paint[C]//Proc of the AIAA Ground Testing Conference. 2013. doi: 10.2514/6.2013-3123 [17] PANDEY A, GREGORY J. Dynamic response characteris-tics of polymer/ceramic pressure-sensitive paint[C]//Proc of the 53rd AIAA Aerospace Sciences Meeting. 2015. doi: 10.2514/6.2015-0021 [18] 高丽敏, 姜衡, 葛宁, 等. 正弦波型高频动态压力光学校准系统及其应用[J]. 航空学报, 2020, 41(10): 123667. doi: 10.7527/S1000-6893.2020.23667GAO L M, JIANG H, GE N, et al. A high frequency dynamic pressure optical calibration system based on sinusoidal wave and its application[J]. Acta Aeronautica et Astronautica Sinica, 2020, 41(10): 123667. doi: 10.7527/S1000-6893.2020.23667 [19] 高丽敏, 欧阳波, 姜衡, 等. 快速响应压力敏感涂料截止频率实验研究[J]. 航空学报, 2023, 44(11): 38–46. doi: 10.7527/S1000-6893.2022.27556GAO L M, OUYANG B, JIANG H, et al. Experimental study on cut-off frequency of fast response pressure sensitive paint[J]. Acta Aeronautica et Astronautica Sinica, 2023, 44(11): 38–46. doi: 10.7527/S1000-6893.2022.27556 [20] SUGIMOTO T, SUGIOKA Y, NUMATA D, et al. Characterization of frequency response of pressure-sensitive paints[J]. AIAA Journal, 2017, 55(4): 1460–1464. doi: 10.2514/1.j054985 [21] LIU T S, SULLIVAN J P, ASAI K, et al. Pressure and temperature sensitive paints[M]. Berlin: Springer, 2005: 30-31. [22] PENG D, GU F, ZHONG Z, et al. Thermal stability improvement of sprayable fast-responding pressure-sensitive paint for measurement above 100℃[J]. Chinese Journal of Aeronautics, 2021, 34(1): 320–326. doi: 10.1016/j.cja.2020.09.040 [23] PENG D, LIU Y Z. Fast pressure-sensitive paint for understanding complex flows: from regular to harsh environments[J]. Experiments in Fluids, 2019, 61(1): 8. doi: 10.1007/s00348-019-2839-6 [24] JIAO L R, PENG D, LIU Y Z. Dynamic response of polymer ceramic pressure-sensitive paint: improved model considering thickness effect[J]. AIAA Journal, 2018, 56(7): 2903–2906. doi: 10.2514/1.J056778 -

下载:

下载: